Preparation method and application thereof for vanadium pentoxide/oxidized graphene composite film

A composite technology of vanadium pentoxide and graphene, which is applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problem of difficulty in applying flexible energy storage devices, poor uniformity of vanadium pentoxide and graphene composite films, Complicated preparation process and other issues to achieve the effect of reducing raw material consumption, easy control and operation, and shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

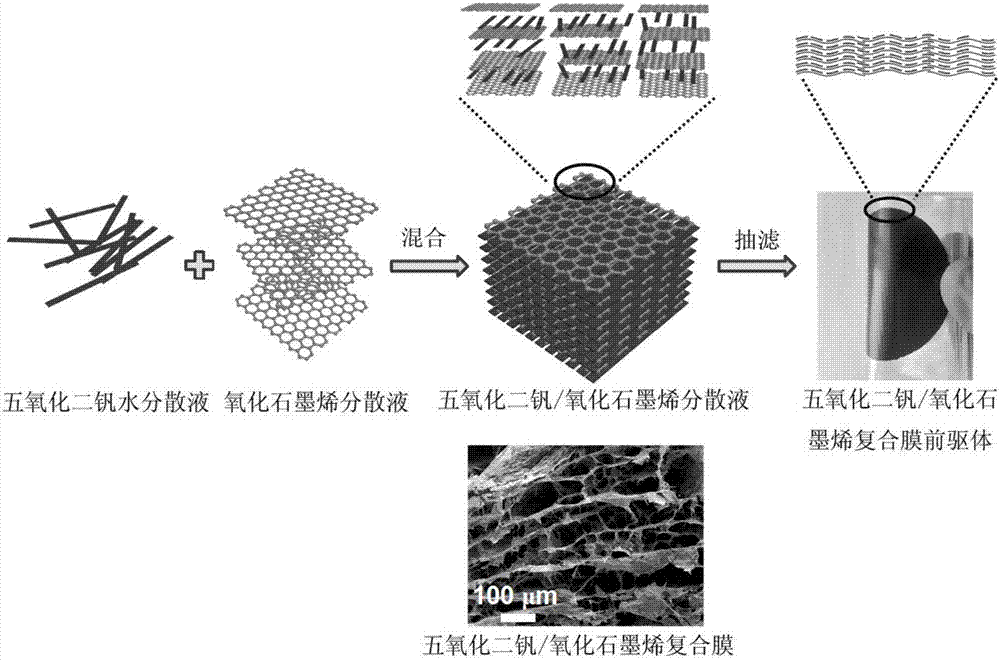

[0036] Such as image 3 Shown, a kind of preparation method of vanadium pentoxide / graphene composite membrane comprises the following steps:

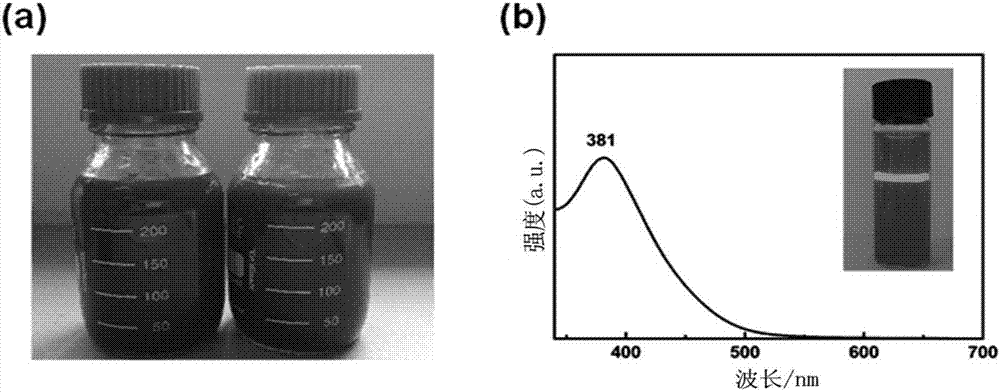

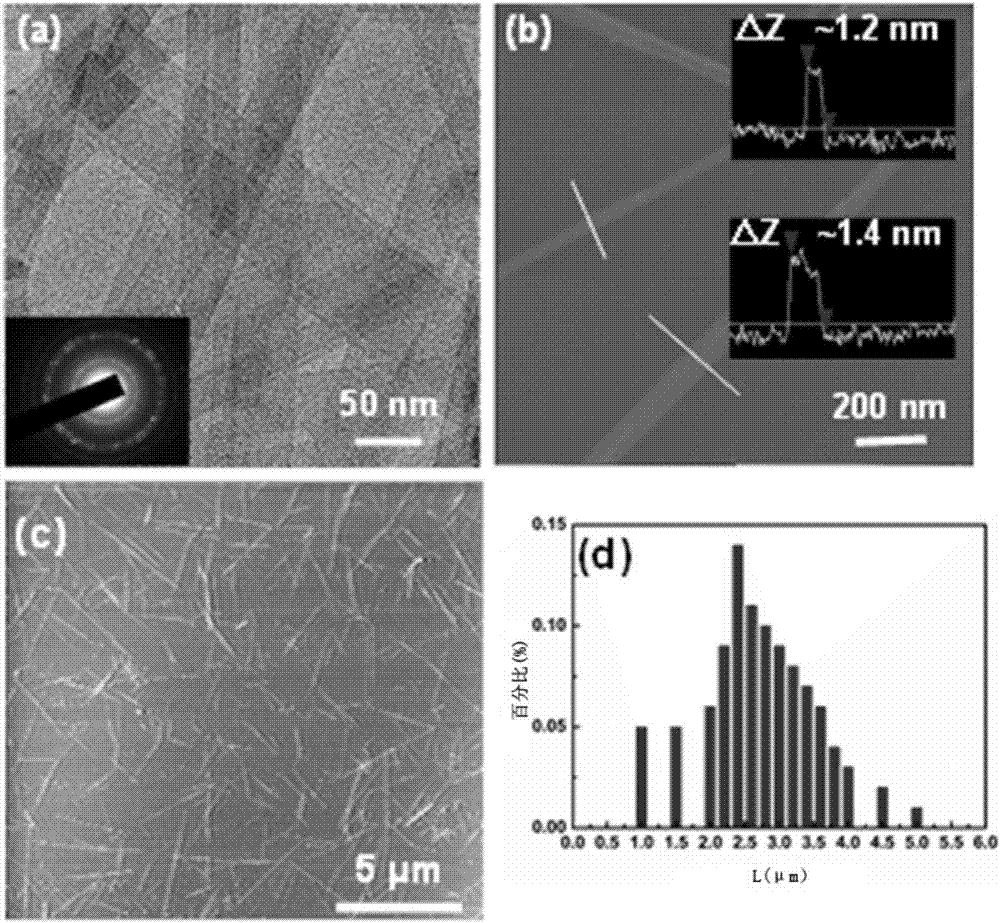

[0037] (a) Preparation of vanadium pentoxide aqueous dispersion: at a room temperature of 20°C, add 0.9g of vanadium pentoxide powder into 63mL of double distilled water and stir, slowly add to the dispersion containing vanadium pentoxide Add 12mL of hydrogen peroxide solution with a mass fraction of 30% dropwise, continue to stir for 1 hour after adding the hydrogen peroxide solution, transfer the mixed solution to a 100mL hydrothermal reaction kettle and react at 180°C for 12 hours, cool the reaction kettle to five An aqueous dispersion of vanadium oxide, the concentration of the dispersion is 12 mg / mL, and the prepared vanadium pentoxide is vanadium pentoxide nanobelts. Such as figure 1 Shown in (a), the aqueous dispersion of the vanadium pentoxide of preparation is very stable, figure 1 (a) the dispersion liquid in the left bottl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Aperture range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com