Stockyard dust emission inhibitor as well as preparation method and application thereof

A technology of inhibitors and stockyards, applied in chemical instruments and methods, other chemical processes, starch derivative coatings, etc., can solve the problems of slow speed, inconvenient operation, dust pollution, etc., to reduce surface tension, formula Scientific and reasonable, enhance the effect of penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: raw materials are measured in parts by weight, and the dust suppressant is used for dust raising in coal yards.

[0040] Dissolve 12 kg of carboxymethyl cellulose and 5 kg of methyl cellulose with 450 kg of water for later use; 6.5 kg of polyvinyl alcohol are dissolved with 120 kg of water for later use; 4 kg of emulsifier, 10 kg of penetrant, and 0.5 kg of film-forming aid are dissolved in 20 kg of water respectively Standby; add 102kg of water into the reaction kettle, start stirring, first pre-mix the dissolved carboxymethyl cellulose, methyl cellulose, polyvinyl alcohol, stir for 0.5h, then add 150kg of oxidized starch, 80kg of EVA emulsion, dissolve The emulsifier, penetrant, and film-forming aid are used, and the stirring is stopped for about 1 hour, and the material is discharged and packaged.

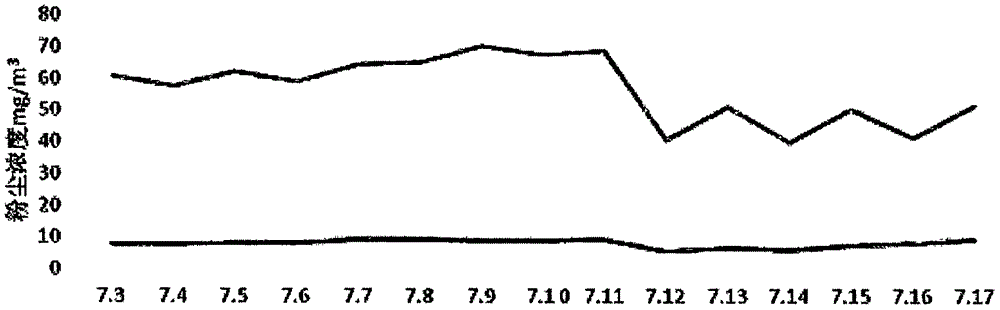

[0041] Dilute the dust inhibitor 15 times and inject it into the high-pressure spraying equipment at 1.8L / m 2Spray evenly once to form a solidified layer o...

Embodiment 2

[0042] Embodiment 2: Raw materials are measured by weight, and the dust suppressant is used for dust in cement plants.

[0043] Dissolve 10kg of hydroxypropyl methylcellulose and 2kg of hydroxyethylcellulose in 465kg for later use; 6kg of polyvinyl alcohol is dissolved in 100kg of water for later use; 4.5kg of emulsifier, 11kg of penetrant, and 1kg of film-forming aid are used in 20kg Dissolve in water for later use; add 140.5kg of water into the reaction kettle, start stirring, first pre-mix the dissolved hydroxypropylmethylcellulose, hydroxyethylcellulose, and polyvinyl alcohol, stir for 0.5h, and then add 140kg of oxidized starch in turn , EVA emulsion 60kg, dissolved emulsifier, penetrant, film-forming aid, stirring for about 1 hour, stop the machine, discharge, and pack.

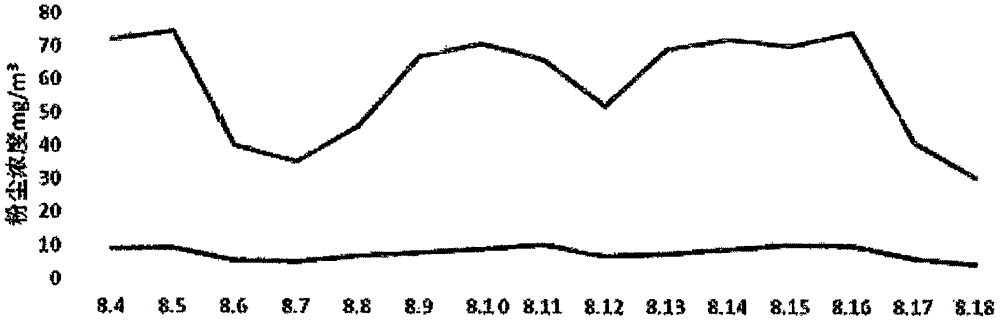

[0044] Dilute the dust inhibitor 12 times and inject it into the high-pressure spraying equipment at 2.0L / m 2 Spray evenly once to form a solidified layer of about 10mm to achieve the effect of dust su...

Embodiment 3

[0045] Embodiment 3: Raw materials are measured by weight, and the dust inhibitor is used for dust in iron and steel factories.

[0046] Dissolve 14 kg of carboxymethyl cellulose and 1 kg of hydroxyethyl cellulose with 440 kg of water for later use; 7 kg of polyvinyl alcohol are heated and dissolved with 135 kg of water for later use; Dissolve for later use; add 109.8kg of water into the reactor, start stirring, pre-mix the dissolved carboxymethyl cellulose, hydroxyethyl cellulose, polyvinyl alcohol, stir for 0.5h, then add 160kg of oxidized starch, EVA emulsion 50kg, dissolved emulsifier, penetrant, film-forming aid, stirring for about 1 hour, stop, discharge, and pack.

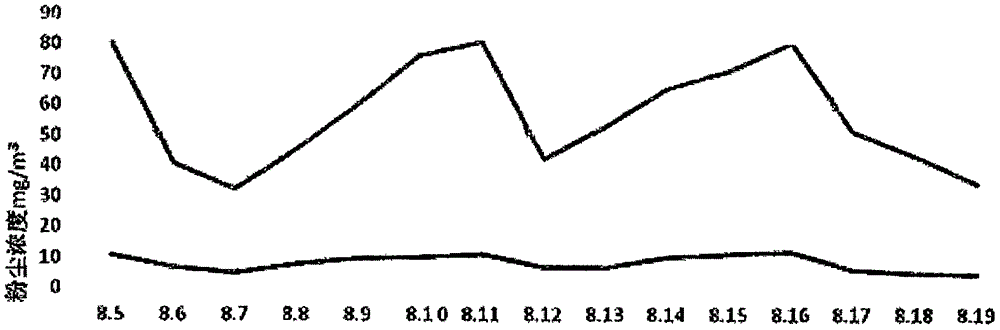

[0047] Dilute the dust inhibitor 20 times and inject it into the high-pressure spraying equipment at 1.5L / m 2 Spray once evenly with the dosage, and spray again evenly after 24 hours to form a solidified layer of about 10mm to achieve the dust suppression effect. The technical indicators of the dust inhibi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com