Durable antibacterial textile fiber and preparation method thereof

A textile fiber and durability technology, applied in the field of chemical fiber preparation, can solve problems affecting spinning strength and quality, poor durability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation method of durable antibacterial textile fiber, comprises the following steps:

[0031] a. Mix nano-scale antibacterial agent nano-silver with polyethylene wax, silica airgel, nylon 6, and high-melt index EVA7660M in a high-mixer for 4 minutes in a mass ratio of 4:8:1:0.8:12, and then Melt and co-extrude with a co-rotating twin-screw extruder, water-cool, pelletize, and dry to obtain antibacterial masterbatch; the co-rotating twin-screw extruder is a 65-type co-rotating twin-screw extruder with an aspect ratio of 42:1 machine;

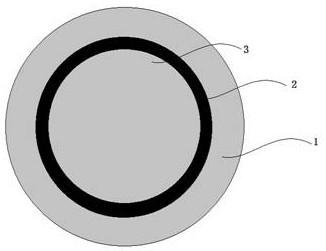

[0032] b. Add nylon 6, the antibacterial masterbatch obtained in step a, and nylon 6 into three screw extruders to melt, and compound them into silk through a multi-layer die head. The inner layer is nylon 6, the middle layer is antibacterial masterbatch, and the outer layer It is nylon 6, and the mass ratio of the inner layer, the middle layer, and the outer layer is 100:8:70, and then stretched into fibers at a speed of 3200m / m...

Embodiment 2

[0034] The preparation method of durable antibacterial textile fiber, comprises the following steps:

[0035] a. Put the nano-scale antibacterial agent nano-scale titanium oxide, polyethylene wax, silica airgel, nylon 6, and high-melt index EVA40L-03 in a high-mixer with a mass ratio of 3:10:1:0.6:12 3min, then melt co-extrusion with a co-rotating twin-screw extruder, water-cooled, pelletized, and dried to obtain antibacterial masterbatch; to the twin-screw extruder;

[0036] b. Add nylon 6, the antibacterial masterbatch obtained in step a, and nylon 6 into three screw extruders to melt, and compound them into silk through a multi-layer die head. The inner layer is nylon 6, the middle layer is antibacterial masterbatch, and the outer layer It is nylon 6, the mass ratio of the inner layer, the middle layer, and the outer layer is 100:9:60, and then it is stretched into fibers at a speed of 2500m / min, and the spinning oil and deionized water are used in a mass ratio of 1:4. Th...

Embodiment 3

[0038] The preparation method of durable antibacterial textile fiber, comprises the following steps:

[0039] a. Mix the nano-scale antibacterial agent rice-grade zinc oxide with polyethylene wax, silica airgel, nylon 6, and high-melt index EVA220W in a high-mixer for 5 minutes at a mass ratio of 5:10:1:1:13 , then melt and co-extrude with a co-rotating twin-screw extruder, water-cool, pelletize, and dry to obtain antibacterial masterbatch; the co-rotating twin-screw extruder is a 65-type co-rotating twin-screw with an aspect ratio of 42:1 extruder;

[0040] b. Add nylon 6, the antibacterial masterbatch obtained in step a, and nylon 6 into three screw extruders to melt, and compound them into silk through a multi-layer die head. The inner layer is nylon 6, the middle layer is antibacterial masterbatch, and the outer layer It is nylon 6, and the mass ratio of the inner layer, the middle layer, and the outer layer is 100:9:60, and then stretched into fibers at a speed of 4000m / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com