A recycling process of waste viscose

A viscose and process technology, applied in the direction of rayon recycling, sustainable manufacturing/processing, textile/flexible product manufacturing, etc., can solve problems such as reducing environmental pressure, achieve the goal of reducing environmental pressure, reducing production costs, and improving production quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

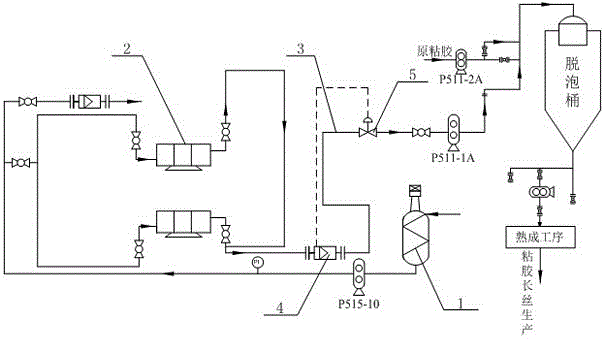

Image

Examples

Embodiment 1

[0027] Regarding the processing technology of the existing waste viscose, we know that after the waste viscose is collected and processed, it is usually reused in the production of viscose short filaments. The existing patent document CN102586954A discloses such a treatment method, which will The waste viscose is collected and processed and then reused in the yellowing machine used in the production of viscose staple yarn, as the raw material for the production of viscose staple yarn. While realizing the production of viscose, it also has the advantages of saving production costs and reducing environmental pollution Index and the production characteristics of improving economic benefits, but for the existing technology, we found that in the known public technology, waste rubber is not directly added to normal viscose, and used for the production of viscose filaments in large production systems, Therefore, for the diversity of waste viscose processing and further reducing the en...

Embodiment 2

[0033] The difference between this embodiment and Embodiment 1 is: in this embodiment, the maturity degree of the waste rubber in the waste rubber collection tank is controlled at 8.8, and the viscose particle content of the waste rubber is controlled at 1000 / ml.

Embodiment 3

[0035] The difference between this embodiment and Embodiment 1 is that the filter involved in this embodiment is a plate and frame filter, wherein the filter cloth of the plate and frame filter consists of two layers of poplin, two layers of plain cloth and one The waste glue sent to the plate and frame filter is filtered through two layers of poplin, two layers of plain cloth and one layer of double fleece in sequence. After filtering, the number of viscose particles in the waste glue is 200 pieces / ml, the viscosity is 38Pa•s, and the maturity is 9.8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com