Grading control cooling process of 600Mpa-grade high-strength anti-seismic weather-proof hot-rolled steel bar

A cooling process and hierarchical control technology, applied in the direction of temperature control, etc., can solve the problems of high C content, poor weather resistance, and inability to ensure the strength-to-yield ratio of seismic indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) The internal control chemical composition of the test steel bar: C 0.22%, Si 0.50%, Mn 1.42%, P 0.028%, S0.021%, Cr 0.15%, V 0.16%, N 280ppm; Fe balance.

[0023] (2) After conventional heating of 160 square billets, hot rolling is carried out. The rolling specification is Φ25mm, the billet heating temperature is 1150°C, the billet exit temperature is 1100°C, and the rolling start temperature is 1050°C. Rough rolling, intermediate rolling, and intermediate rolling The cooling between finishing and finishing rolling is mainly based on water tank rapid cooling, the average cooling speed is controlled at 20°C / s, the finishing rolling speed is 14m / s, and the finishing rolling temperature is controlled at 1050°C;

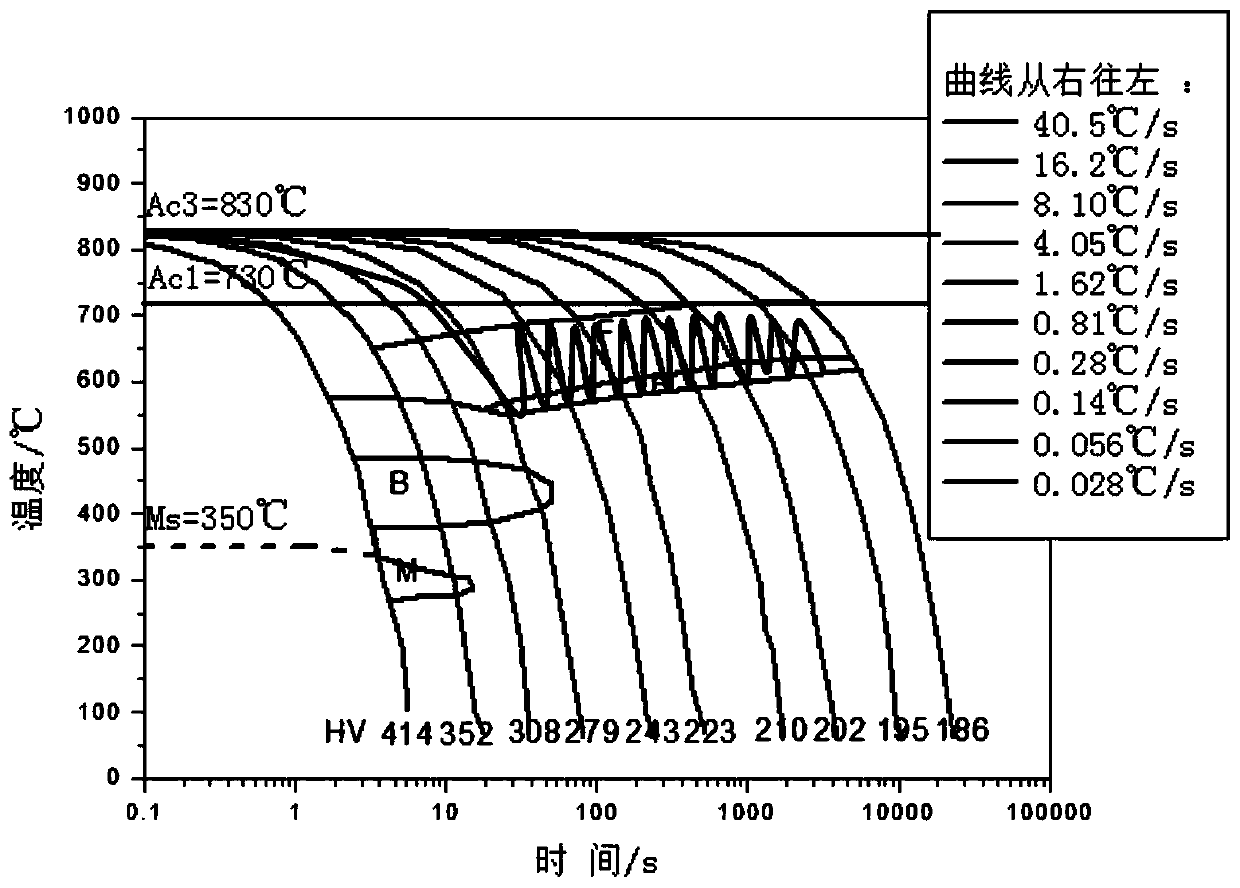

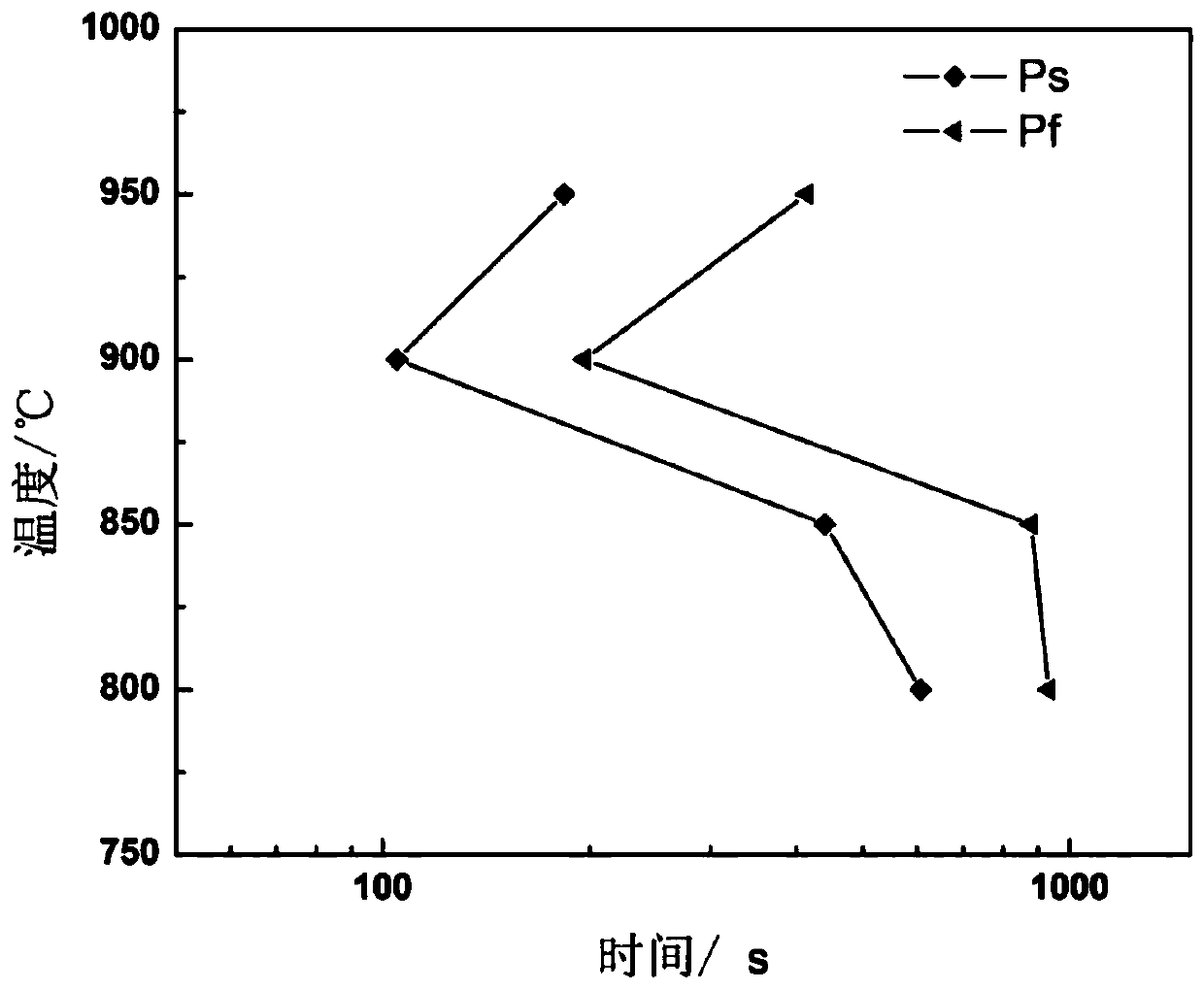

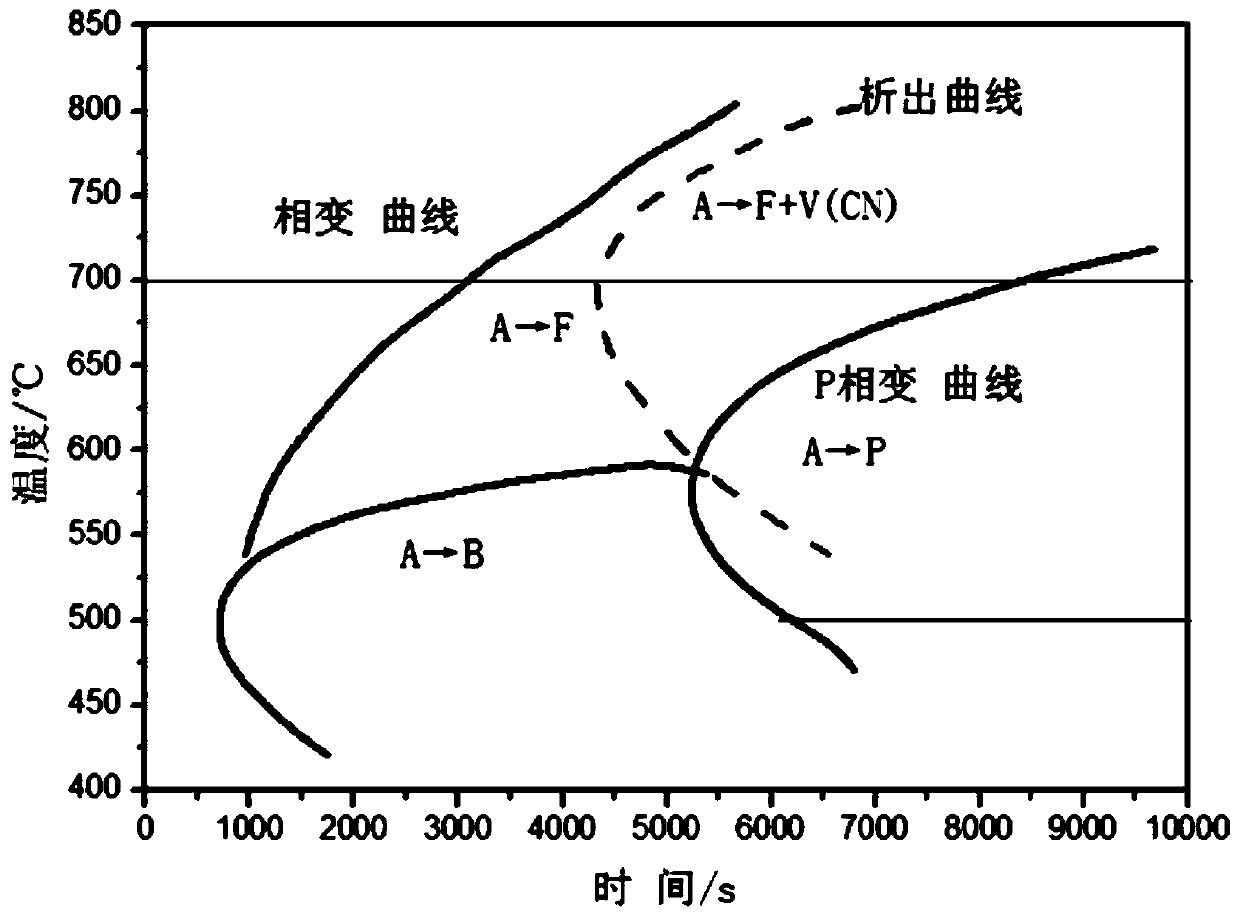

[0024] (3) Adopt the step-by-step control cooling process of fast cooling-returning temperature-fast cooling-returning temperature cycle, the total cooling time is controlled in stages for 1.5s, and the minimum temperature is adjusted according to the CCT curve...

Embodiment 2

[0027] (1) The internal control chemical composition of test steel bar HRB600E: C 0.20%, Si 0.50%, Mn 1.50%, P0.0024%, S 0.028%, V 0.10%, N243ppm, Cr0.5%, Ni0.9%; quantity.

[0028] (2) After conventional heating of 150 square billets, hot rolling is carried out. The rolling specification is Φ25mm. The cooling between rolling and finishing rolling is mainly based on water tank rapid cooling, the average cooling speed is controlled at 40°C / s, the final rolling speed is 14m / s, and the final rolling temperature is controlled at 900°C;

[0029] (3) Adopt the stepwise controlled cooling process of fast cooling-returning temperature-fast cooling-returning temperature cycle, control the total cooling time in stages to 2s, adjust the minimum temperature ≥ 550°C according to the CCT curve and precipitation curve, and the maximum surface cooling speed V cooling At 175°C / s, control the temperature of the cooling section to be in the optimum temperature zone of the pearlite phase transfo...

Embodiment 3

[0032] (1) The internal control chemical composition of test steel bars: C 0.24%, Si 0.65%, Mn 1.55%, P 0.028%, S0.021%, Cr 0.2%, V 0.014%, N 200ppm, Ni0.5%; Fe balance .

[0033] (2) After conventional heating of 160 square billets, hot rolling is carried out. The rolling specification is Φ12mm, the billet heating temperature is 1150°C, the billet exit temperature is 1100°C, and the rolling start temperature is 1050°C. Rough rolling, intermediate rolling, and intermediate rolling The cooling between finishing and finishing rolling is mainly based on water tank rapid cooling, the average cooling speed is controlled at 30°C / s, the finishing rolling speed is 15m / s, and the finishing rolling temperature is controlled at 900°C;

[0034] (3) Adopt the step-by-step control cooling process of fast cooling-returning temperature-fast cooling-returning temperature cycle, the total cooling time is controlled in stages to 0.8s, and the minimum temperature is adjusted according to the CCT ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com