Butt-joint low-resistance lead for electronic packaging and manufacturing method thereof

An electronic packaging, low-resistance lead technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems that the resistance is not suitable for the passage of large current, the space is limited, the lead is increased, and the structure is simple, The effect of convenient processing and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

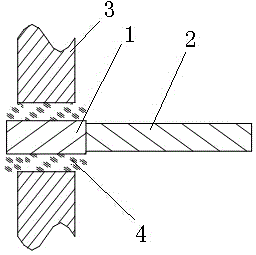

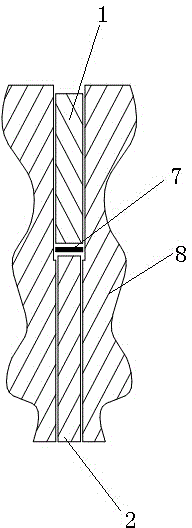

[0038] like figure 1 As shown, the butt-joint low-resistance lead for electronic packaging is formed by butting the ends of the feed-through lead segment 1 and the low-resistance lead segment 2 through resistance welding or brazing coaxial welding. The material of the low-resistance lead segment 2 A metal material having a resistivity lower than that of the feedthrough lead segment 1 is selected, and the resistivity of the metal material is ≤2 μΩ·cm. The length of the feedthrough lead segment 1 matches the length of the encapsulating glass 4 , and the diameter is larger than that of the low-resistance lead segment 1 .

[0039] Preferably, the low-resistance lead segment 2 is made of oxygen-free copper, zirconium bronze or diffused oxygen-free copper. Feedthrough lead section 1 is a low-expansion metal lead material with a linear expansion coefficient of 4-10ppm / ℃, including iron-nickel alloys (such as Kovar alloy, 4J50 alloy, etc.) and iron-nickel alloy-clad copper lead mater...

Embodiment 2

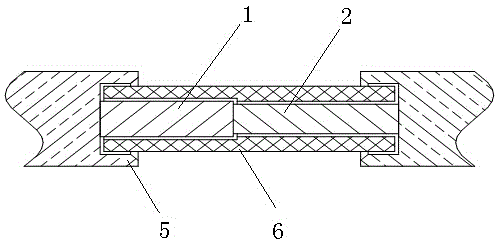

[0042] like figure 2 As shown, the resistance welding method of butt-type low-resistance leads for electronic packaging, the steps are as follows:

[0043] (1) Use a grinder to grind the butt end faces of the feedthrough lead segment 1 and the low resistance lead segment 2, so that the flatness of the end face is 0.01 mm and the surface roughness is 0.8 μm, and then the end faces of the two lead segments to be welded are stacked perpendicular to the horizontal plane Neat, restrained by a metal ring, the front and back sides are ground into a smooth plane, and the burrs are removed;

[0044](2) Put the feedthrough lead segment 1 and the low-resistance lead segment 2 through the positioning insulating sleeve 6, and the length of which extends out of the positioning insulating sleeve 6 is 1 mm, so as to ensure that the two lead segments will not be bent and deformed after the end face is stressed; Clamp the positioning insulating sleeve 6 on both sides of the welding electrode ...

Embodiment 3

[0047] use as figure 2 The resistance welding method shown, the steps are as follows:

[0048] (1) Use a grinder to grind the butt end faces of the feedthrough lead segment 1 and the low resistance lead segment 2, so that the flatness of the end face is 0.008 mm and the surface roughness is 0.87 μm, and then the end faces of the two lead segments to be welded are vertical to the horizontal plane and stacked neatly. Constrained by a metal ring, the front and back sides are ground into smooth planes respectively, and the burrs are removed;

[0049] (2) Put the feedthrough lead segment 1 and the low-resistance lead segment 2 through the positioning insulating sleeve 6, and extend the length of the positioning insulating sleeve 6 by 0.5mm to ensure that the two lead segments will not be bent and deformed after the end face is stressed; Clamp the positioning insulating sleeve 6 on both sides of the welding electrode 5, adjust the power of the resistance welding machine to reach t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Linear expansion coefficient | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com