Anode for electrolytic manganese metal and preparation method thereof

A technology of electrolytic manganese metal and anode, applied in the direction of electrodes, electrolytic components, electrolytic process, etc., can solve the problems of low electric efficiency, increased cell voltage, high energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

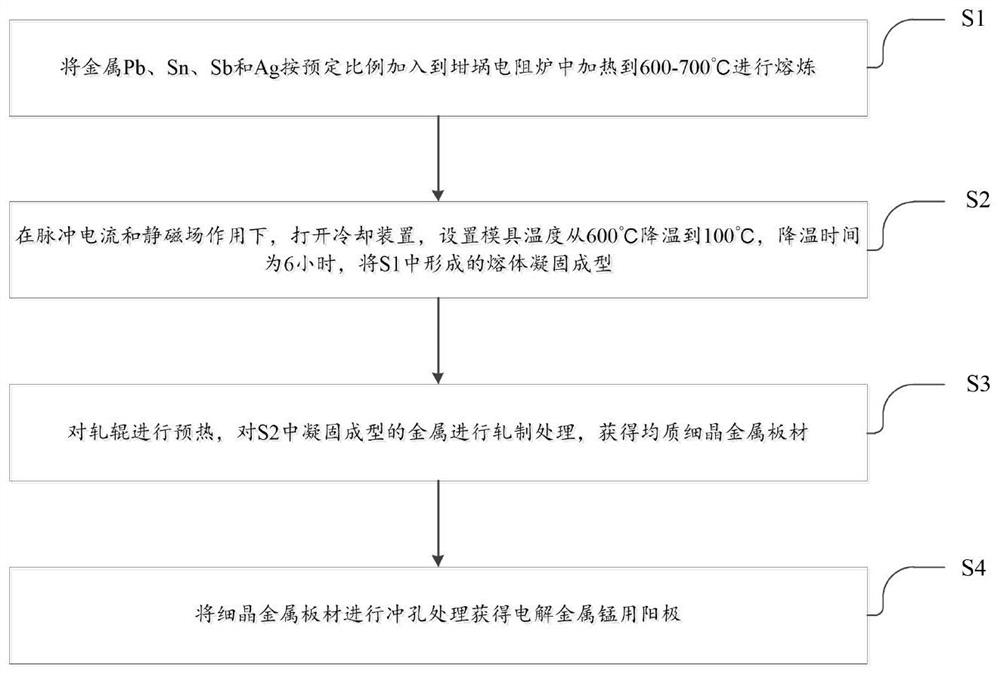

[0024] A kind of preparation method of anode for electrolytic manganese metal, the concrete steps are as follows:

[0025] (a) According to the mass percentage, the chemical composition is Sn1.5%, Sb2%, Ag0.2%, and the balance is Pb, after weighing the ingredients, heat to 650°C in a crucible resistance furnace for smelting;

[0026] (b) Under the action of pulse current and static magnetic field, turn on the cooling device, set the temperature of the mold to cool down from 600°C to 100°C, and the cooling time is 6 hours to solidify the melt;

[0027] (c) preheating the roll, and rolling the solidified metal to obtain a homogeneous fine-grained metal plate with a thickness of 6 mm;

[0028] (d) punching the metal plate with a hole diameter of 20 mm to finally obtain an anode for electrolytic manganese metal.

[0029] The anode of the novel electrolytic manganese metal prepared in the present embodiment is placed in the manganese electrolyte, and the anode is placed in the man...

Embodiment 2

[0031] A kind of preparation method of anode for electrolytic manganese metal, the concrete steps are as follows:

[0032] (a) According to the mass percentage, the chemical composition is Sn2%, Sb1.5w%, Ag0.2%, and the balance is Pb, and after weighing the ingredients, heat to 650°C in a crucible resistance furnace for smelting;

[0033] (b) Under the action of pulse current and static magnetic field, turn on the cooling device, set the temperature of the mold to cool down from 600°C to 100°C, and the cooling time is 6 hours to solidify the melt;

[0034] (c) preheating the roll, and rolling the solidified metal to obtain a homogeneous fine-grained metal plate with a thickness of 6 mm;

[0035] (d) punching the metal plate with a hole diameter of 20 mm to finally obtain an anode for electrolytic manganese metal.

[0036]The anode of the novel electrolytic manganese metal prepared in the present embodiment is placed in the manganese electrolyte, and the anode is placed in the...

Embodiment 3

[0038] A kind of preparation method of anode for electrolytic manganese metal, the concrete steps are as follows:

[0039] (a) According to the mass percentage, the chemical composition is Sn2.5%, Sb1%, Ag0.2%, and the balance is Pb, after weighing the ingredients, heat to 650°C in a crucible resistance furnace for smelting;

[0040] (b) Under the action of pulse current and static magnetic field, turn on the cooling device, set the temperature of the mold to cool down from 600°C to 100°C, and the cooling time is 6 hours to solidify the melt;

[0041] (c) preheating the roll, and rolling the solidified metal to obtain a homogeneous fine-grained metal plate with a thickness of 6 mm;

[0042] (d) punching the metal plate with a hole diameter of 20 mm to finally obtain an anode for electrolytic manganese metal.

[0043] The anode of the novel electrolytic manganese metal prepared in this example is placed in the manganese electrolyte, and the Mn 2+ Concentration 35g / L, pH=7.5, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com