A kind of ce-al-cu-ag bulk amorphous alloy and preparation method

A ce-al-cu-ag, amorphous alloy technology, applied in the field of Ce-Al-Cu-Ag bulk amorphous alloy and its preparation, can solve the problem of poor superplastic processing ability, low glass forming ability and supercooling Problems such as the narrow liquid phase region, to achieve the effect of being beneficial to plastic processing and forming, the improvement of width and glass forming ability, and the wide plastic processing and forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Preparation of Ce 70 Al 10 Cu 20 Bulk amorphous alloy

[0027] Step 1: Combine Ce with a purity of 99.5wt%, Al with 99.9wt% and Cu with 99.9wt% in accordance with Ce 70 Al 10 Cu 20 The specified molar ratio is used for ingredients;

[0028] Step 2: Put the above ingredients uniformly into an electric arc furnace, perform arc smelting in an argon atmosphere adsorbed by titanium, and cool to obtain a master alloy ingot;

[0029] Step 3: Remelt the master alloy ingot obtained above under the above conditions, and suck the master alloy melt into a water-cooled copper mold with an inner diameter of 3mm using the adsorption device in the electric arc furnace to obtain Ce 70 Al 10 Cu 20 Bulk amorphous alloy.

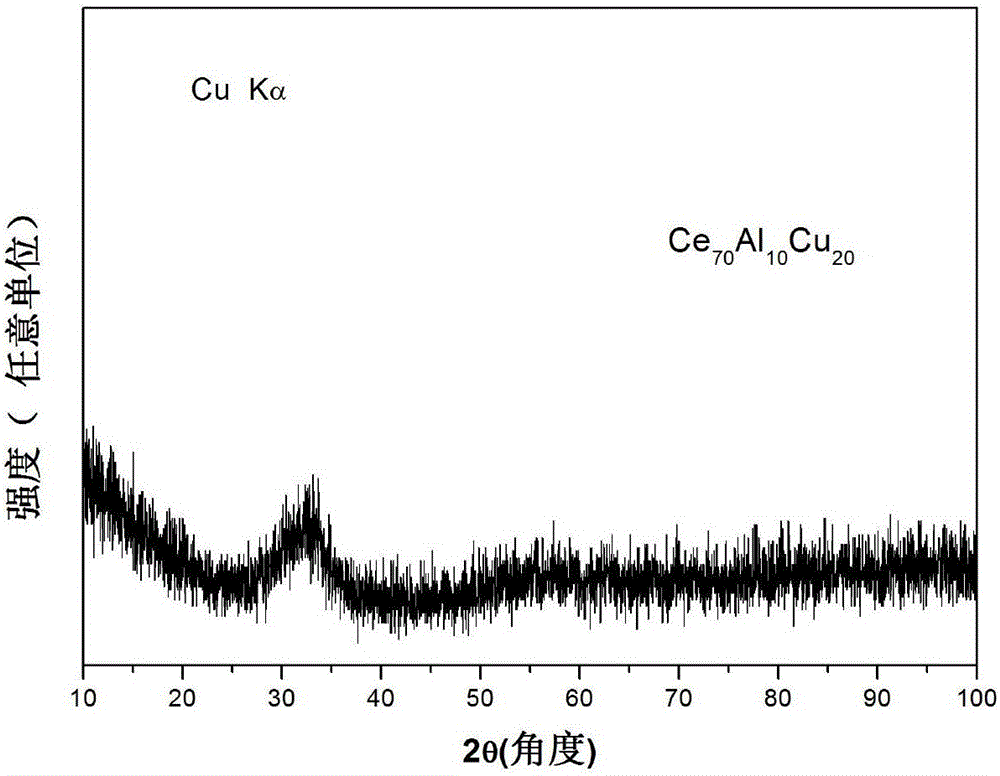

[0030] X-ray diffraction (XRD) was used to detect the structural features of bulk amorphous alloys. The XRD results of the alloy are as follows figure 1 Shown.

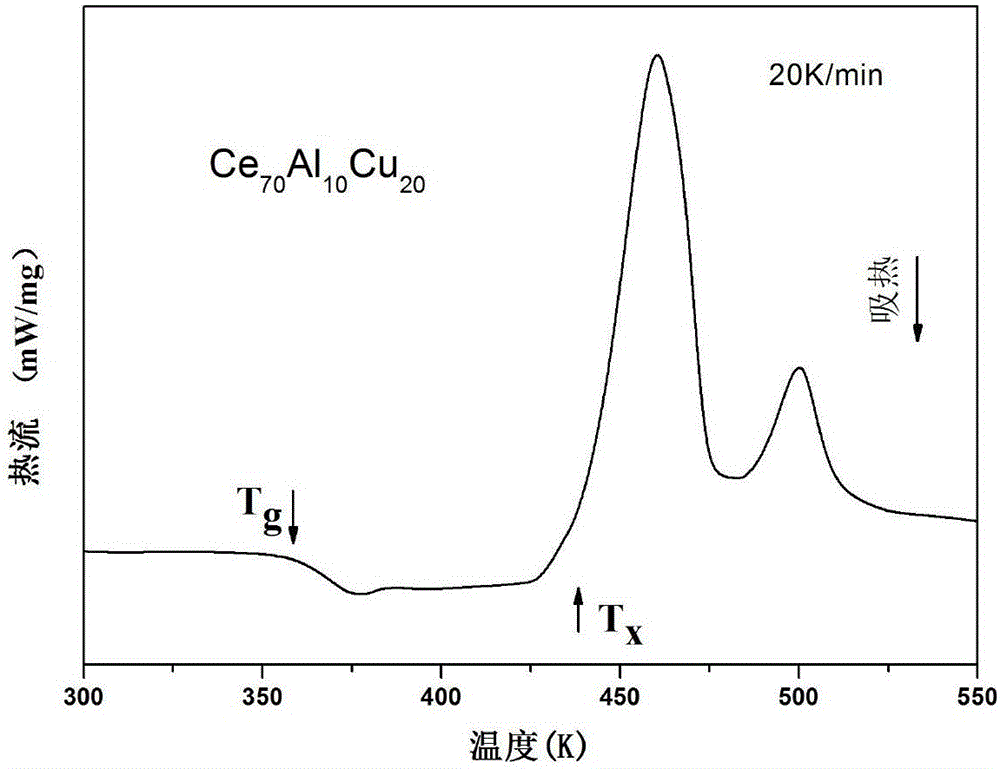

[0031] Differential scanning calorimetry (DSC) was used for thermodynamic analysis of the alloy, and the re...

Embodiment 2

[0032] Example 2: Preparation of Ce 69 Al 10 Cu 20 Ag 1 Bulk amorphous alloy

[0033] Step 1: Set the purity of 99.5wt% Ce, 99.9wt% Al, 99.9wt% Cu and 99.9wt% Ag according to Ce 69 Al 10 Cu 20 Ag 1 The specified molar ratio is used for ingredients;

[0034] Step 2: Put the above ingredients uniformly into an electric arc furnace, arc smelt in an argon atmosphere adsorbed by titanium, and cool to obtain a master alloy ingot;

[0035] Step 3: Remelt the master alloy ingot obtained above under the above conditions, and suck the master alloy melt into a water-cooled copper mold with an inner diameter of 5mm by using the adsorption device in the electric arc furnace to obtain Ce 69 Al 10 Cu 20 Ag 1 Bulk amorphous alloy.

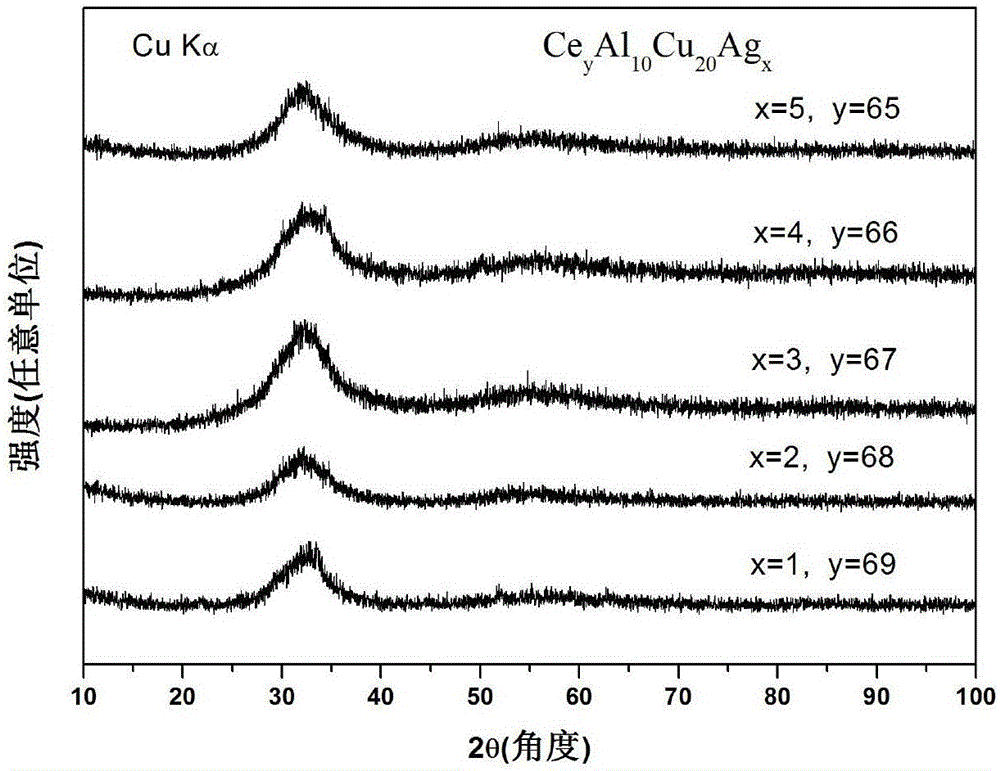

[0036] X-ray diffraction (XRD) was used to detect the structural features of bulk amorphous alloys. The XRD results of the alloy are as follows image 3 Shown.

[0037] Differential scanning calorimetry (DSC) was used for thermodynamic analysis of the alloy, and the relate...

Embodiment 3

[0038] Example 3: Preparation of Ce 68 Al 10 Cu 20 Ag 2 Bulk amorphous alloy

[0039] Step 1: Set the purity of 99.5wt% Ce, 99.9wt% Al, 99.9wt% Cu and 99.9wt% Ag according to Ce 68 Al 10 Cu 20 Ag 2 The specified molar ratio is used for ingredients;

[0040] Step 2: Put the above ingredients uniformly into an electric arc furnace, arc smelt in an argon atmosphere adsorbed by titanium, and cool to obtain a master alloy ingot;

[0041] Step 3: Remelt the master alloy ingot obtained above under the above conditions, and suck the master alloy melt into a water-cooled copper mold with an inner diameter of 7mm by using the adsorption device in the electric arc furnace to obtain Ce 68 Al 10 Cu 20 Ag 2 Bulk amorphous alloy.

[0042] X-ray diffraction (XRD) was used to detect the structural features of bulk amorphous alloys. The XRD results of the alloy are as follows image 3 Shown.

[0043] Differential scanning calorimetry (DSC) was used for thermodynamic analysis of the alloy, and the relate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical dimension | aaaaa | aaaaa |

| critical dimension | aaaaa | aaaaa |

| critical dimension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com