Patents

Literature

40results about How to "Suitable for industrial processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for removing nitrites in cubilose

The invention relates to a method for removing nitrites in cubilose, belonging to the technical field of standard-exceeding components in food. The nitrites in the cubilose are removed by combining an ultrasonic technology and an ozone technology, therefore, the content of the nitrites in the cubilose is reduced to be below 30mg / kg, and the cup type and the color of the cubilose can be kept unchangeable. The method comprises the following steps: putting the cubilose in water for ultrasonic treatment for 10-30min with ultrasonic power of 50-2500W and ultrasonic frequency of 20-50 kHz; washing with water for three times, placing into an ozone generator for ozone treatment for 6-120 min by using the water as a medium; and naturally drying. The invention can keep the cup type and the color of the cubilose unchangeable; no chemicals are added, the product after the ozone is oxidized is water without harmful substances so that the cubilose and the environment can not be polluted; the method is an environmental-friendly treatment technology; the ozone has the sterilizing function, and the treated cubilose is not easy to mould; and the invention has simple process, little equipment input and cost saving, and is suitable for the industrialized treatment.

Owner:厦门市燕之屋丝浓食品有限公司

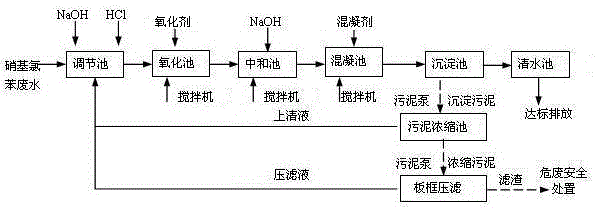

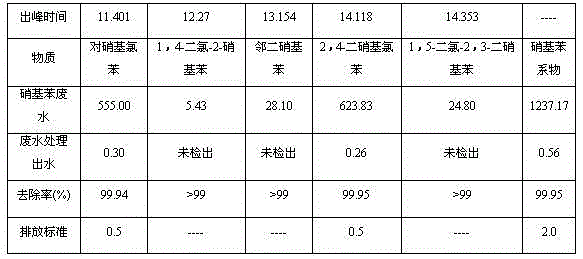

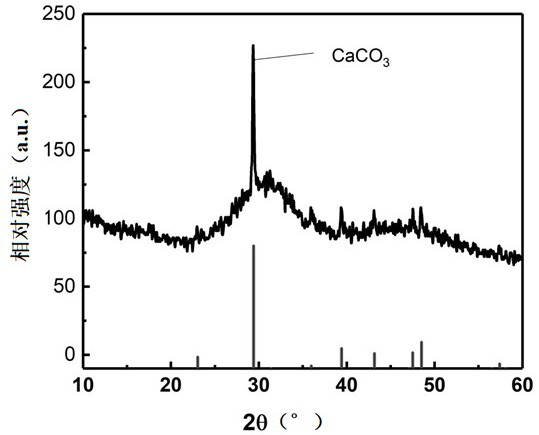

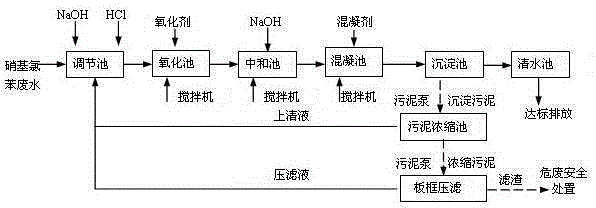

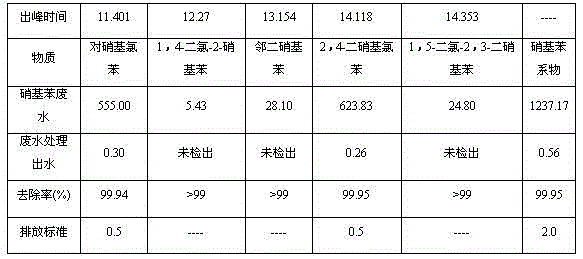

Treatment method and treatment system for nitrochlorobenzene production waste water

InactiveCN103951101AImprove processing efficiencyLow running costMultistage water/sewage treatmentSludgeFiltration

A treatment method and a treatment system for nitrochlorobenzene production waste water. The method comprises the following steps: pumping nitrochlorobenzene production waste water into an adjustment pool, adjusting the pH value to allow the waste water to be acidic, then allowing the waste water to enter an oxidation pool, adding oxidizing agents of sodium hypochlorite, calcium hypochlorite or hypochloric acid for chemical oxidation treatment, discharging the effluent from the oxidation pool into a neutralization pool, adjusting the pH value to allow the effluent to be neutral, discharging the effluent from the neutralization pool into a coagulation pool, adding coagulants of one or more than one of polyaluminium chloride, polyferric chloride, and polyacrylamide for a coagulation reaction, discharging the effluent from the coagulation pool into a sedimentation pool, allowing a supernatant obtained by sedimentation and separation in the sedimentation pool to overflow into a clean water pool, discharging the clean water that reaches the standard, concentrating and filtering sedimentated sludge at the bottom of the sedimentation pool for safety treatment, and discharging waste liquid generated during the concentration and filtration process into the adjustment pool for re-treatment. According to the invention, the removal rate of nitrochlorobenzene and other nitrobenzene compounds in effluent of the nitrochlorobenzene production waste water treated by the method of the invention is up to 99%, and the method of the invention has the advantages of high treatment efficiency, low operation cost, no secondary pollution, and the like.

Owner:LUOYANG INST OF SCI & TECH

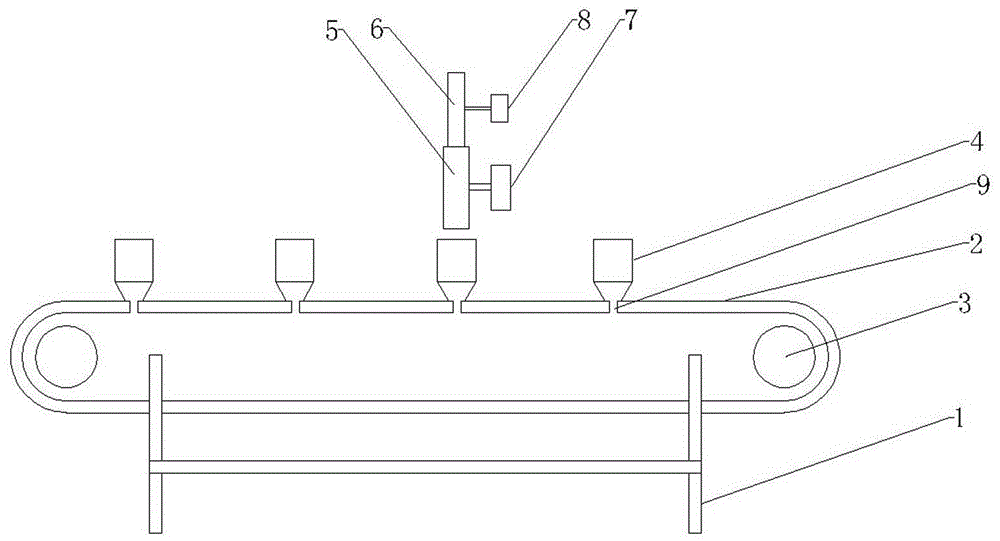

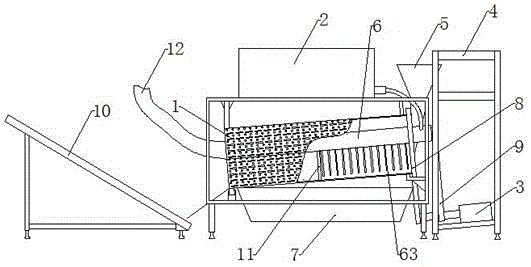

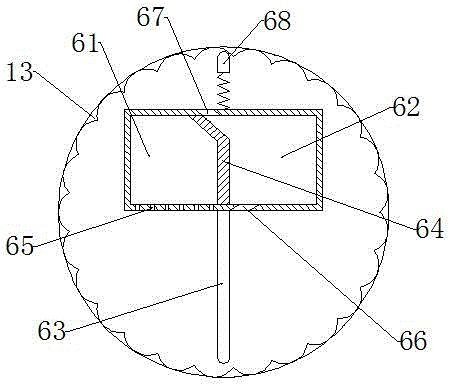

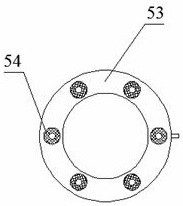

Stauntonvine fruit pitting machine

InactiveCN105752594AAvoid destructionReduce resistanceConveyorsFruit stoningReciprocating motionEngineering

The invention belongs to the field of fruit and vegetable processing equipment and discloses a stauntonvine fruit pitting machine to solve the problems that a large amount of manual operation is needed in an existing pitting machine, and large-batch pitting cannot be achieved. The stauntonvine fruit pitting machine comprises a rack, a conveying belt and a motor. A plurality of round through holes are formed in the conveying belt, fixing cups are connected to the round through holes and are vertically arranged, the interiors of the fixing cups are communicated with the round through holes, the diameter of the bottom ends of the fixing cups is larger than the diameter of the round through holes, a pitting device is arranged above the conveying belt and comprises a first air cylinder, a second air cylinder, a pitting pipe and a propelling column, the first air cylinder is connected with the pitting pipe, the pitting pipe reciprocates in the vertical direction and is of a through hollow structure, the propelling column is located in the pitting pipe, the second air cylinder is connected with the propelling column, and the propelling column reciprocates in the pitting pipe in the vertical direction. By means of the stauntonvine fruit pitting machine, pitting work of a large quantity of stauntonvine fruits can be achieved with one person, continuous processing can be achieved, and the production efficiency is high.

Owner:贵州天楼生物发展有限公司

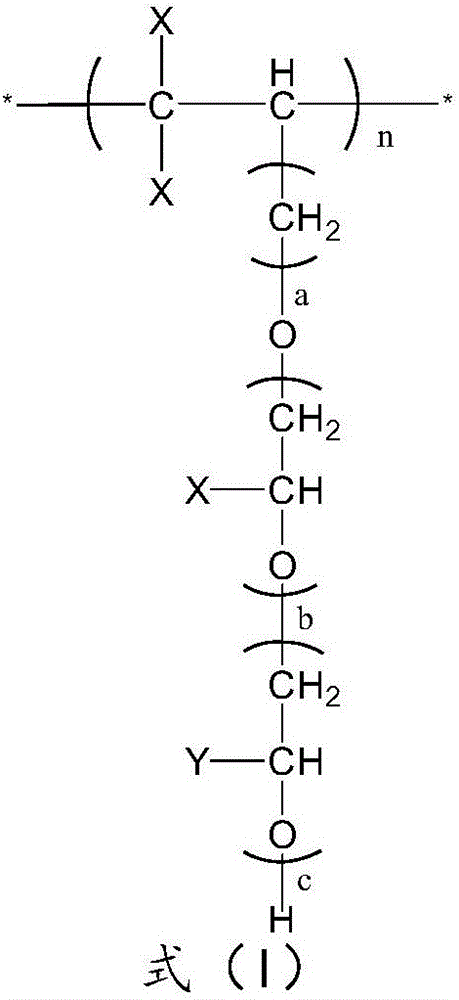

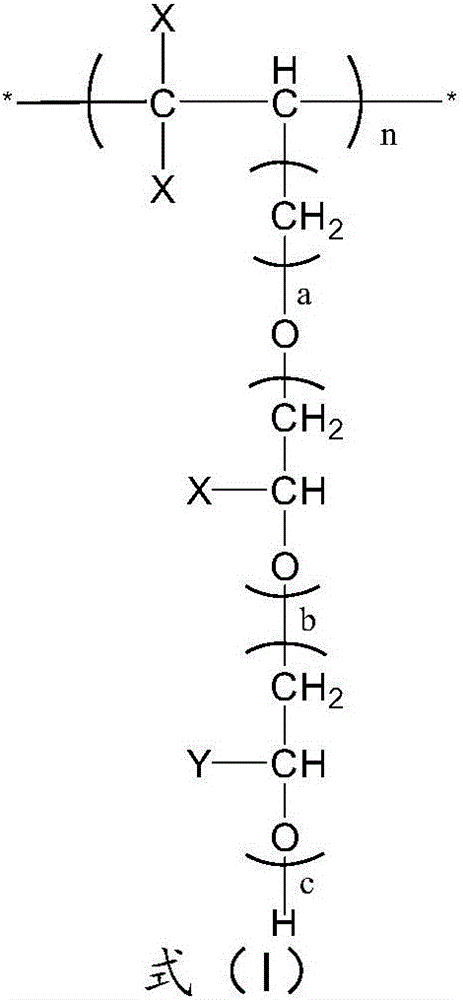

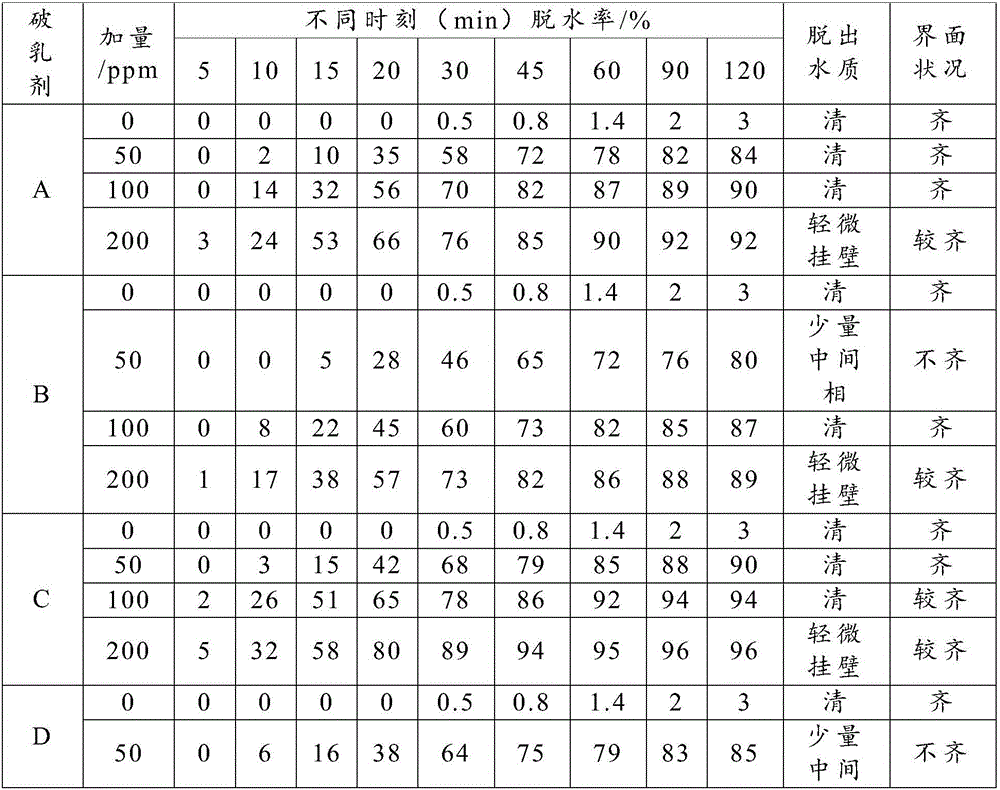

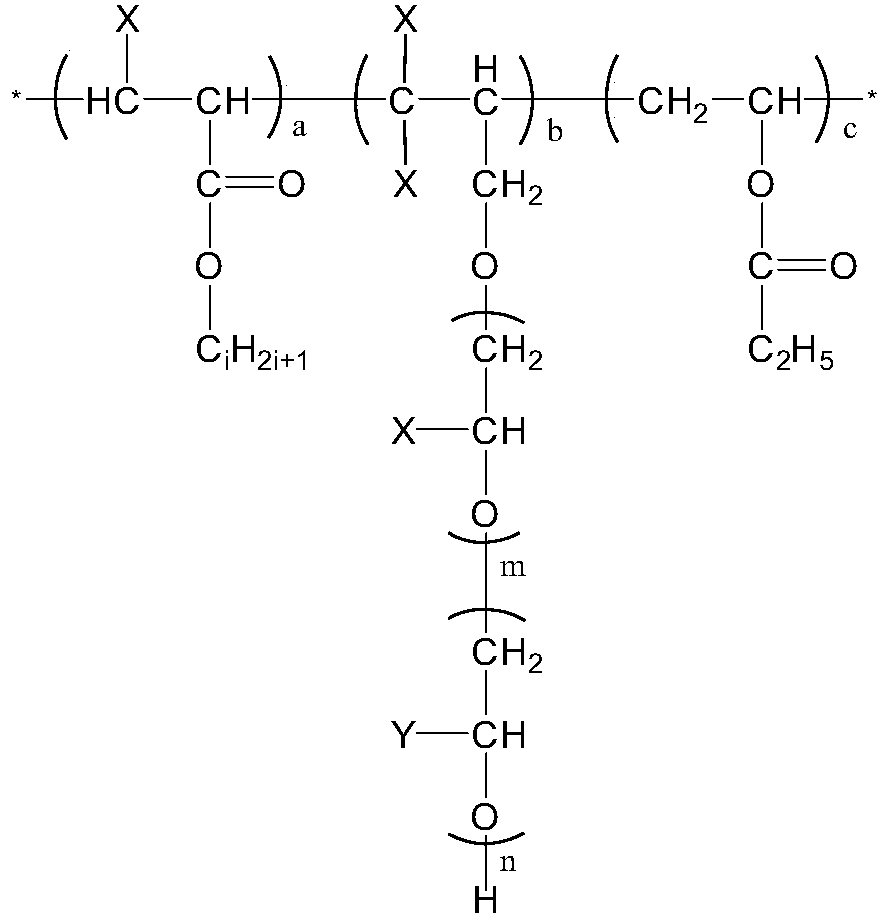

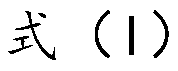

Crude oil demulsifying agent and preparation method thereof

ActiveCN106674452AFast dehydrationOut of waterDewatering/demulsification with chemical meansHydrocarbon oils treatmentAlcoholEther

The invention provides a crude oil demulsifying agent and a preparation method thereof, belonging to the field of crude oil demulsification and dewatering. The crude oil demulsifying agent has the advantages of rapid dewatering, clear water after dewatering, wide adaptive range of crude oil, and the like. The crude oil demulsifying agent uses double bond-contained unsaturated alcohol as an initiator, initiates anionic ring-opening polymerization of propylene oxide and ethylene oxide under the action of a catalyst to obtain poly-oxypropylene-poly-oxyethylene ether of unsaturated alcohol, and initiates polymerization under the action of the initiator. The crude oil demulsifying agent provided by the invention can be used in crude oil demulsification and dewatering process.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

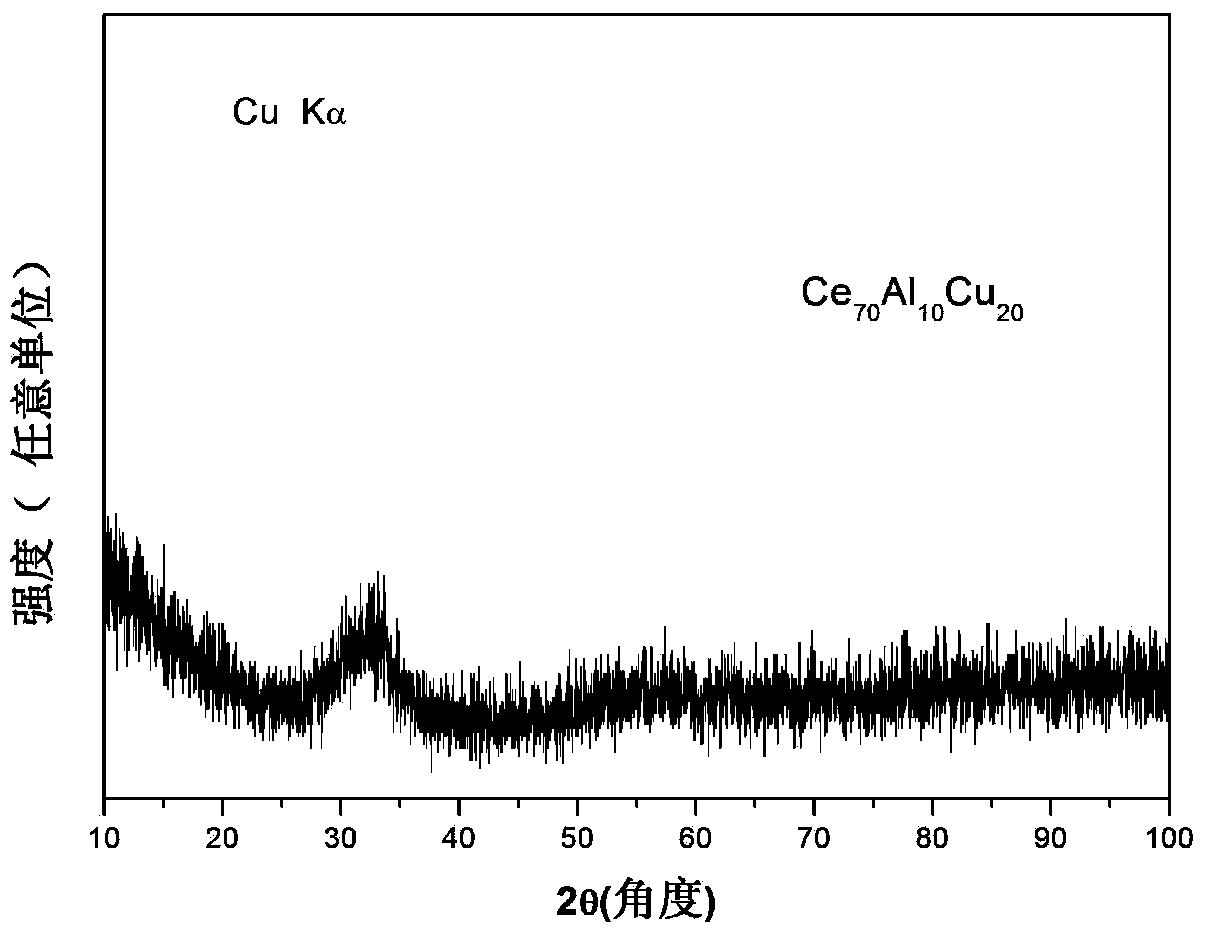

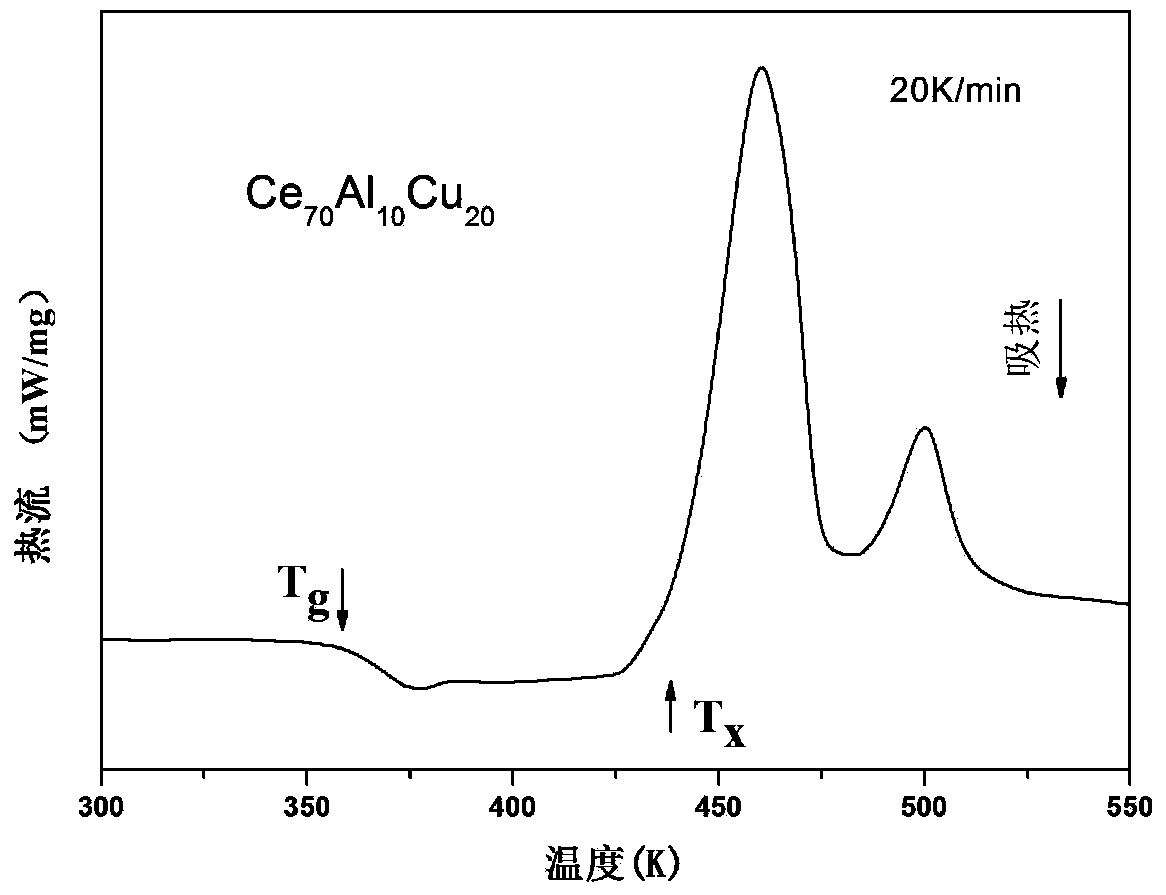

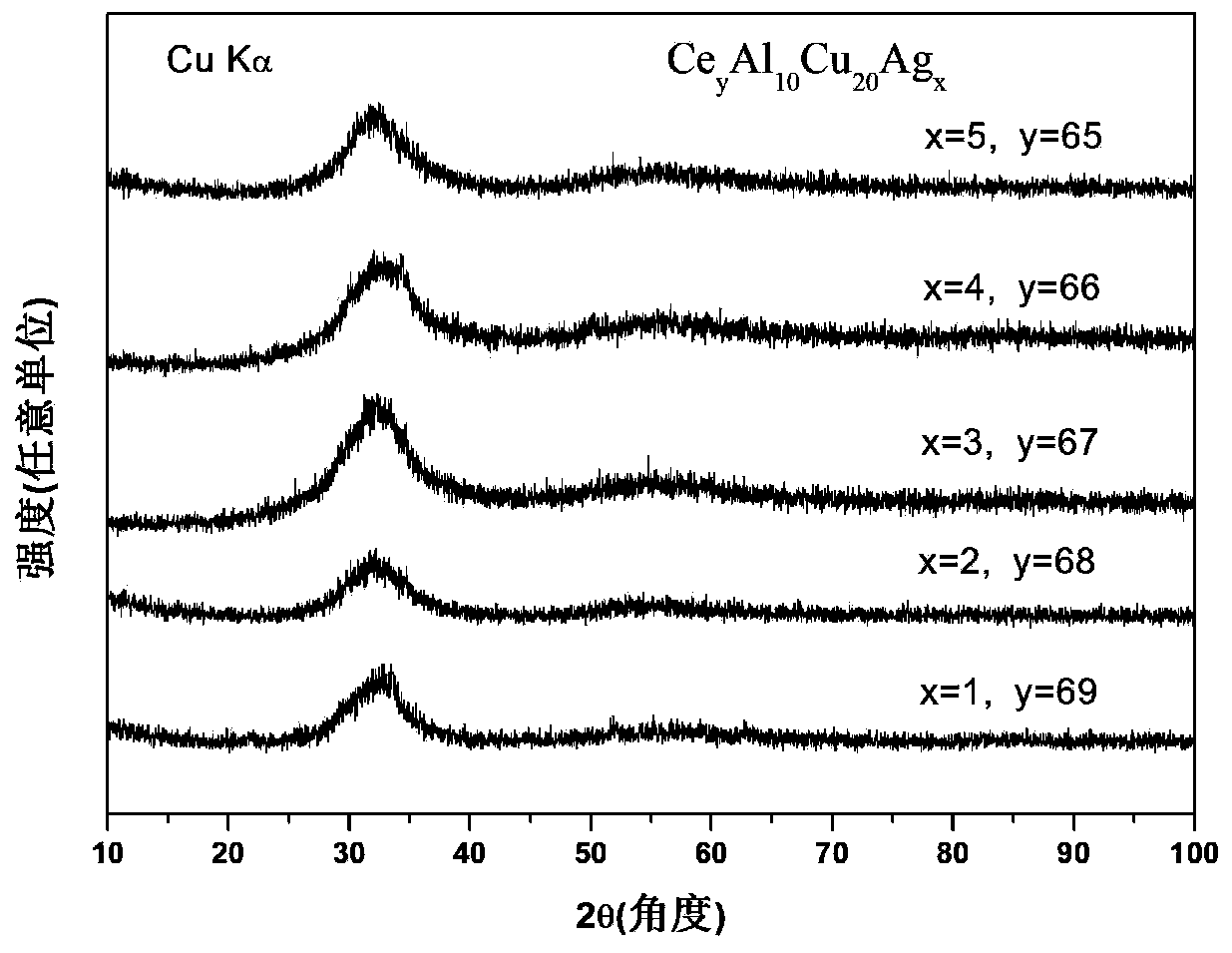

Ce-Al-Cu-Ag bulk amorphous alloy and preparation method thereof

ActiveCN103938126AImprove industrial applicabilityIncreased width and glass forming capacityAg elementLiquid phase

The invention relates to a Ce-Al-Cu-Ag bulk amorphous alloy with a low glass transition temperature and a wide supercooled liquid region. By taking Ce70Cu20Al10 as a basic component and the metal element Ag which belongs to the same main group with Cu as an alloying element, the composition of the alloy is determined by the follow formula: CeyAl10Cu20Agx, wherein x is the atomic percentage of the metal element Ag, y is the atomic percentage of Ce, x is greater than or equal to 1 but less than or equal to 5, y is greater than or equal to 65 but less than or equal to 69, and (x+y)=70. The alloy can form the bulk amorphous alloy with the critical dimension no less tan 3mm and the maximum supercooled liquid region reaching 95K. The alloy integrates low glass transition temperature, wide supercooled liquid region and good glass forming capacity. By means of the low glass transition temperature similar to a common polymer, the alloy can be used as an ideal material which researches phase change and structural relaxation of the metallic glass. By means of excellent conductivity and near-room-temperature super-plastic forming property, the alloy is expected to have a good application prospect in precise components and nano-meter fabrication.

Owner:UNIV OF SCI & TECH BEIJING

Treatment method of chemical nickel plating waste liquid

ActiveCN110759540AAchieve recyclingImprove processing efficiencyWater contaminantsCalcium/strontium/barium fluoridesPhosphoric acidNickel sulphate

A treatment method of chemical nickel plating waste liquid comprises the following steps: (1) adding calcium hydroxide into the chemical nickel plating waste liquid to react, and filtering to obtain primary filtrate and filter residues 1; (2) adding calcium hydroxide into the primary filtrate, introducing ozone for oxidation reaction, and filtering to obtain oxidized filtrate and filter residues 2; (3) adding calcium hydroxide into the oxidized filtrate to react, and filtering to obtain standard filtrate and filter residues 3; (4) combining the filter residues 1, 2 and 3, adding a sulfuric acid solution for leaching, and filtering to obtain nickel sulfate primary filtrate and filter residues 4; (5) adding sodium fluoride into the nickel sulfate primary filtrate for reaction, adjusting thepH value, standing and filtering to obtain nickel sulfate filtrate and calcium fluoride slag; (6) adding zirconium sulfate into the nickel sulfate filtrate to react, standing and filtering to obtain anickel sulfate purified solution and zirconium phosphate slag; and (7) adjusting the pH value of the nickel sulfate purified solution, reacting, and filtering. The method is high in wastewater treatment efficiency, free of secondary discharge, capable of recycling nickel, simple in process, low in cost and suitable for industrial treatment.

Owner:湖南中湘春天环保科技有限公司

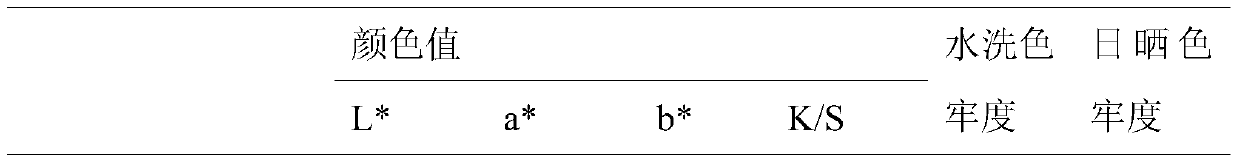

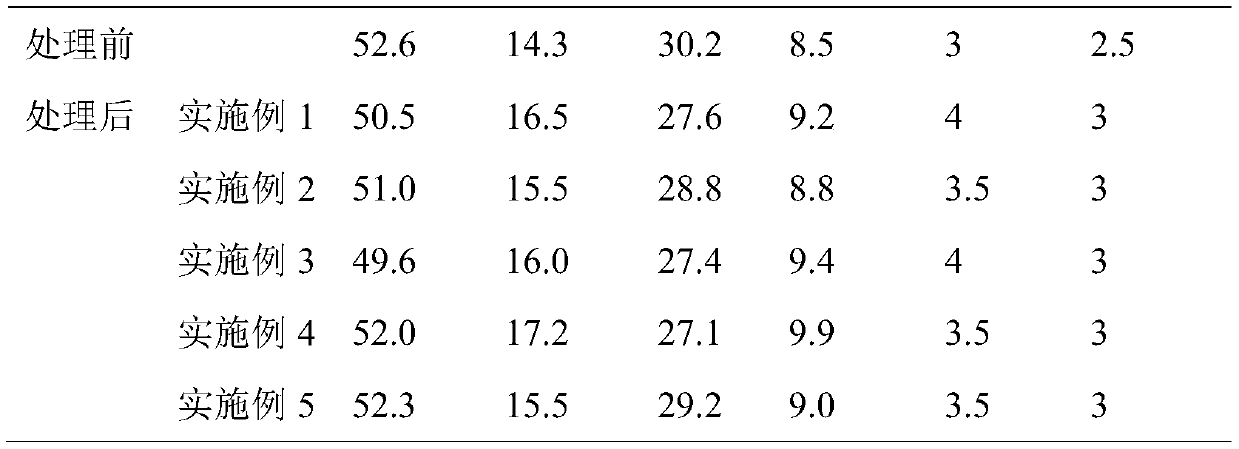

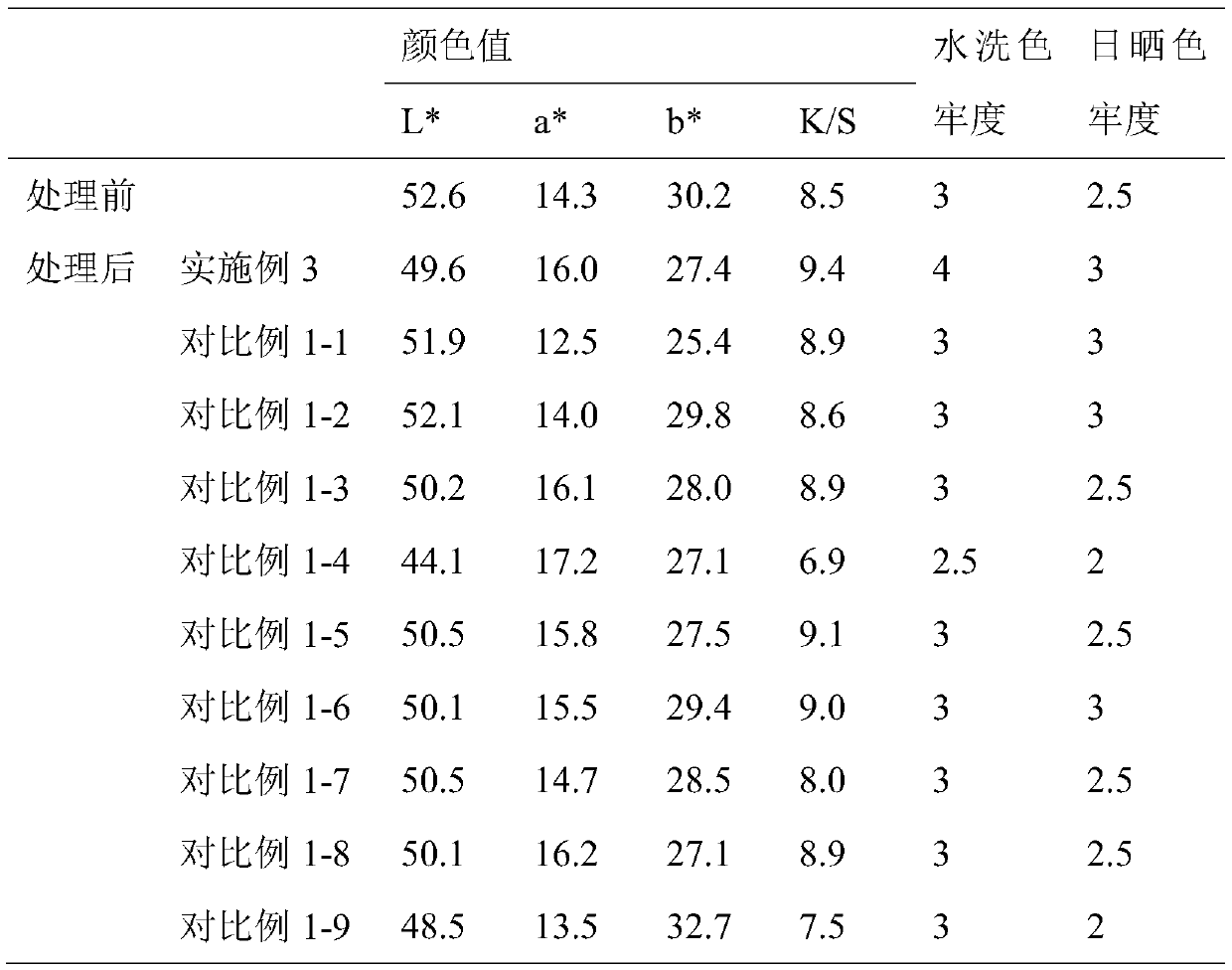

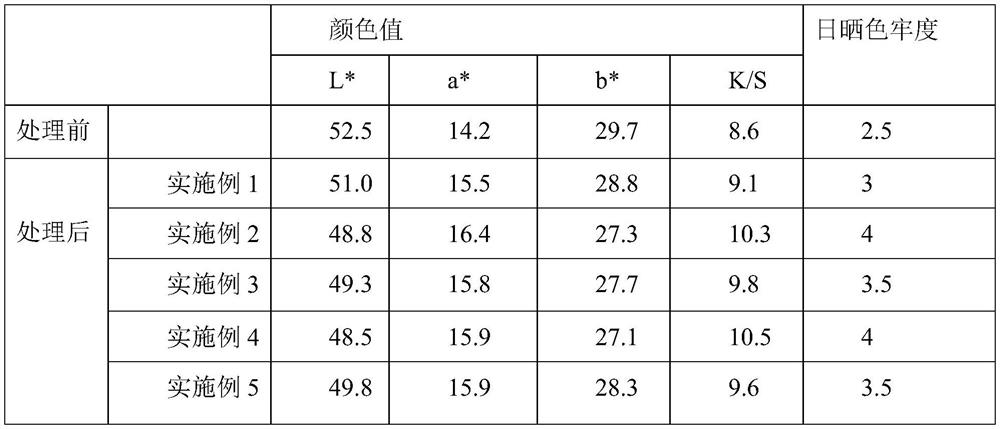

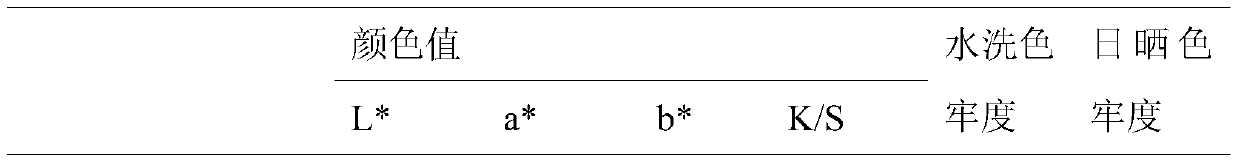

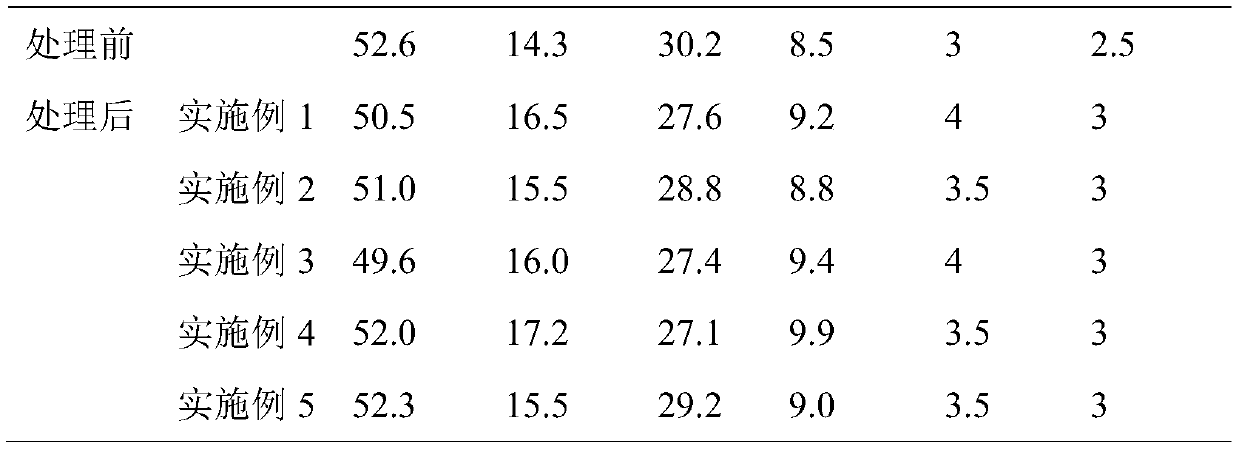

Processing method for improving natural colored cotton color depth and colour and luster stability

The invention discloses a processing method for improving the natural colored cotton color depth and colour and luster stability. The method comprises the steps that natural colored cotton obtained after color fixing is washed and dried; the natural colored cotton is dried, then the natural colored cotton obtained after drying is subjected to liquid ammonia treatment, and the natural colored cotton after liquid ammonia treatment is obtained; gelatin, penetrant and water are mixed to form a protein solution, then the protein solution is adjusted to reach the pH being 2.0-7.0, and a treatment solution is obtained; the natural colored cotton obtained after liquid ammonia treatment is put in the treatment solution for padding at 15-70 DEG C, so that the liquid-carrying rate of natural coloredcotton obtained after padding is 30-150%, and then cold reactor placement is conducted; the natural colored cotton after fixing treatment is obtained. By means of the method, the color of the naturalcolored cotton can become brighter, and the color is obviously deepened and become more uniform; the color fastness to washing and sunshine can be effectively improved.

Owner:ZHEJIANG SCI-TECH UNIV

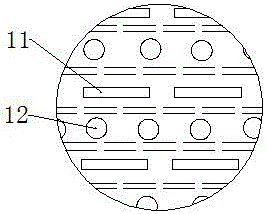

Fresh chili automatic screening device

The invention discloses a fresh chili automatic screening device. A main part of the device is an inclined classification roller; round holes and strip-shaped holes are axially arranged on the wall of the classification roller in rows; the classification roller is provided with separation bars on the inner sides of the joint places of the round holes and the strip-shaped holes; a screening pipe is axially arranged in the classification roller; a separation plate is arranged in the screening pipe for dividing the screening pipe into a water washing pipe and a winnowing pipe; multiple comb needles are spaced at the bottom end of the separation plate; a water spraying hole is formed in the water washing pipe; a strip-shaped incision is axially formed in the bottom wall of the winnowing pipe; a fan is arranged at one end of the winnowing pipe, and is connected with a roller power device; the other end of the winnowing pipe is connected with a slag discharge pipe; a water tank is arranged above the classification roller; and one end of the water washing pipe is communicated with the water tank. The device can screen off impurities of chilies, can clean the chilies, can finish the work, finished by traditional multiple procedures, only through one power device, reduces the labor and time consumption in the chili processing process, and reduces the production cost.

Owner:遵义椒源食品有限公司

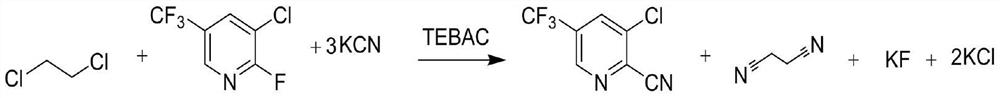

Combined preparation method of 2-cyano-3-chloro-5-trifluoromethylpyridine and succinonitrile

InactiveCN112390747AEasy to recycleLess waste waterPreparation by cyanide reactionCarboxylic acid nitrile purification/separationPtru catalystPotassium cyanide

The invention discloses a combined preparation method of 2-cyano-3-chloro-5-trifluoromethylpyridine and succinonitrile, and belongs to the field of organic chemistry. The method comprises the following steps: taking 2-fluoro-3-chloro-5-trifluoromethylpyridine and dichloroethane as raw materials, reacting in a potassium cyanide / sodium solution under the action of a phase transfer catalyst to obtaina mixed solution of 2-cyano-3-chloro-5-trifluoromethylpyridine and succinonitrile, layering, washing with water, and rectifying to obtain the 2-cyano-3-chloro-5-trifluoromethylpyridine with the content of more than 99% and the succinonitrile with the content of more than 99.9%. According to the method, the yield is high, the wastewater treatment is simple, byproducts are fully utilized, the yieldof the 2-cyano-3-chloro-5-trifluoromethylpyridine can reach 93%, and the yield of the succinonitrile can reach 95%.

Owner:内蒙古佳瑞米精细化工有限公司

Preparation method of organic fertilizer

InactiveCN106748433ASuitable for industrial processingBio-organic fraction processingBiological combination treatmentMixed materialsMushroom

The invention discloses a preparation method of an organic fertilizer. The preparation method is characterized by comprising the following steps: compounding: preparing raw materials of the organic fertilizer, mixing a biological starter with the raw materials, and performing uniform mixing; fermentation: implementing aerobic fermentation on the configured raw materials to generate spawns, and then performing stacking and anaerobic digestion for compost, wherein a mixed material subjected to fermentation contains greater than or equal to 80% of an organic matter, greater than or equal to 8% of NPK, greater than or equal to 5% of amino acid and greater than or equal to 0.21 g / kg of bio-fungus; curing: enabling the mixed material subjected to the fermentation step (2) to enter a curing plant, stabilizing ingredients, then enabling the product to enter a production plant, and performing breaking and screening, wherein the diameters of the screened materials are smaller than 10 mm; granulation: extruding and granulating the mixture by a granulator, and then, performing low-temperature drying to produce the organic fertilizer. The preparation method has the following advantages: the organic fertilizer produced by the process is suitable for serving as fertilizer concentrates for planting matrices and various plants, and is suitable for large-scale industrial processing of mushroom residues and animal and plant organic raw materials.

Owner:东兴易新环保科技有限公司

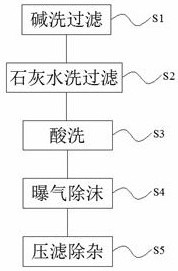

Hydrofluoric acid wastewater purification treatment process

InactiveCN112811713ASuitable for industrial processingConvenient for centralized dischargeWater contaminantsMultistage water/sewage treatmentActivated sludgeFiltration

The invention provides a hydrofluoric acid wastewater purification treatment process, and belongs to the technical field of industrial wastewater treatment. The hydrofluoric acid wastewater purification treatment process comprises the five steps of: alkali washing filtration, lime water washing filtration, acid pickling, aeration defoaming and filter pressing impurity removal, specifically, hydrofluoric acid wastewater is sequentially subjected to alkali liquor washing filtration to remove sodium fluoride and alkaline organic matter, lime water washing filtration to remove calcium fluoride and alkaline organic matter and acid pickling to remove alkaline residues and organic matter; supernatant enters an aeration chamber, after aeration combined activated sludge treatment, a large number of organic matter impurities are subjected to flocculating settling, foam formed by aeration wraps suspended solids to be conveniently discharged in a concentrated mode; the supernatant enters a filter pressing chamber, purified water with the fluorine ion concentration reaching the standard is obtained after filter pressing and impurity removal are conducted. The method is suitable for industrial treatment of hydrofluoric acid wastewater.

Owner:马鞍山蒹葭电子科技有限公司

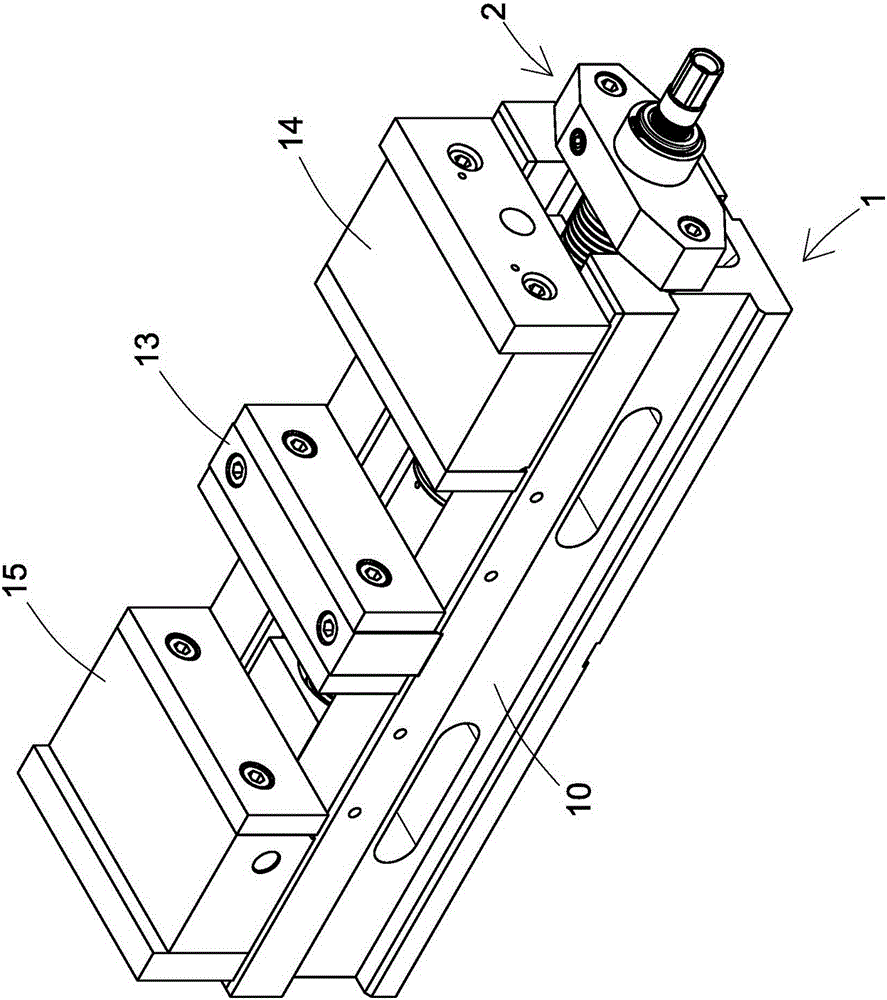

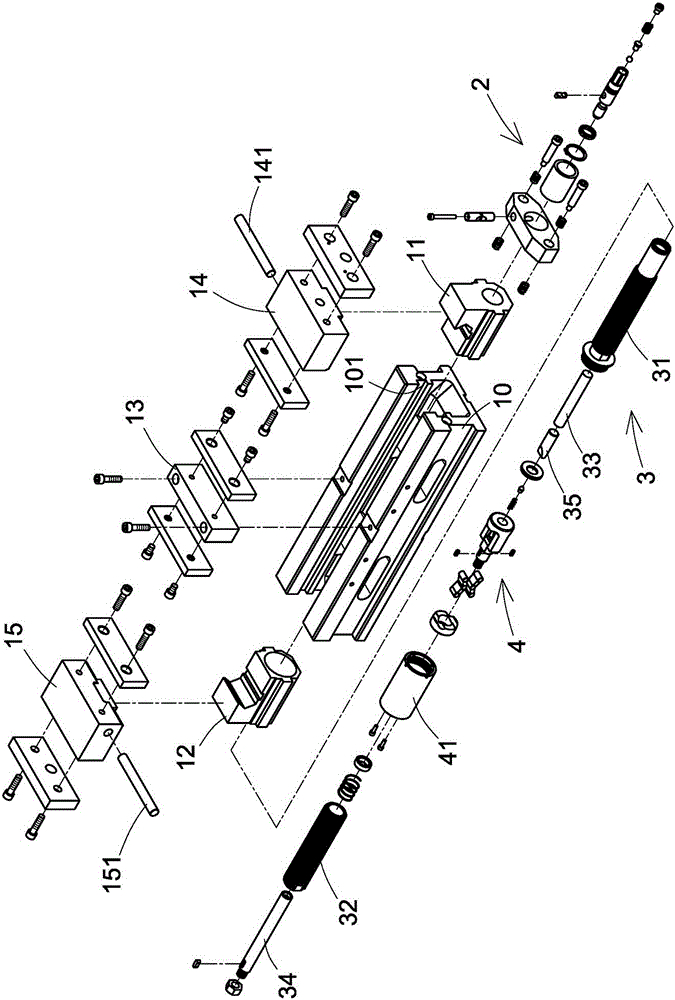

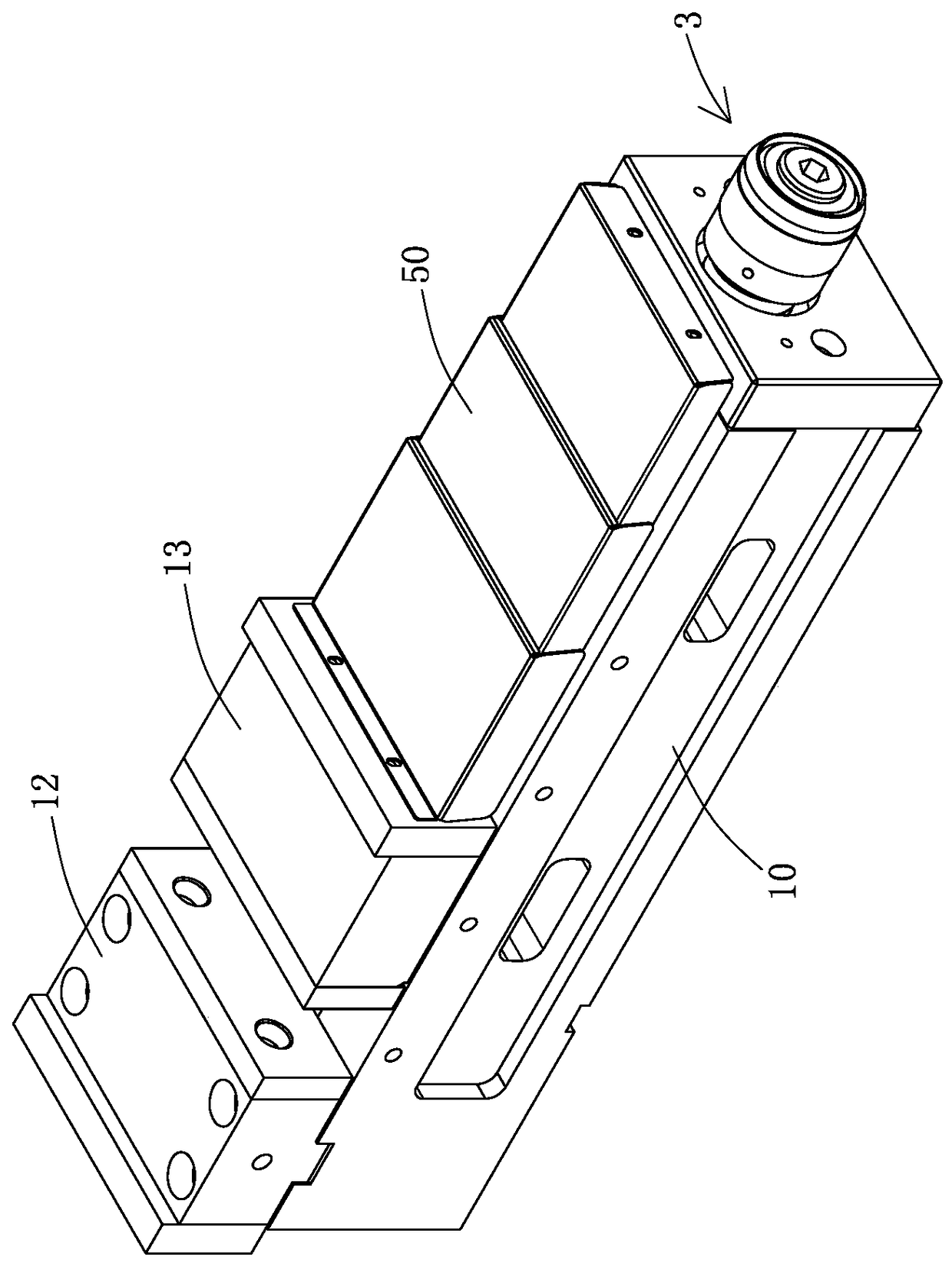

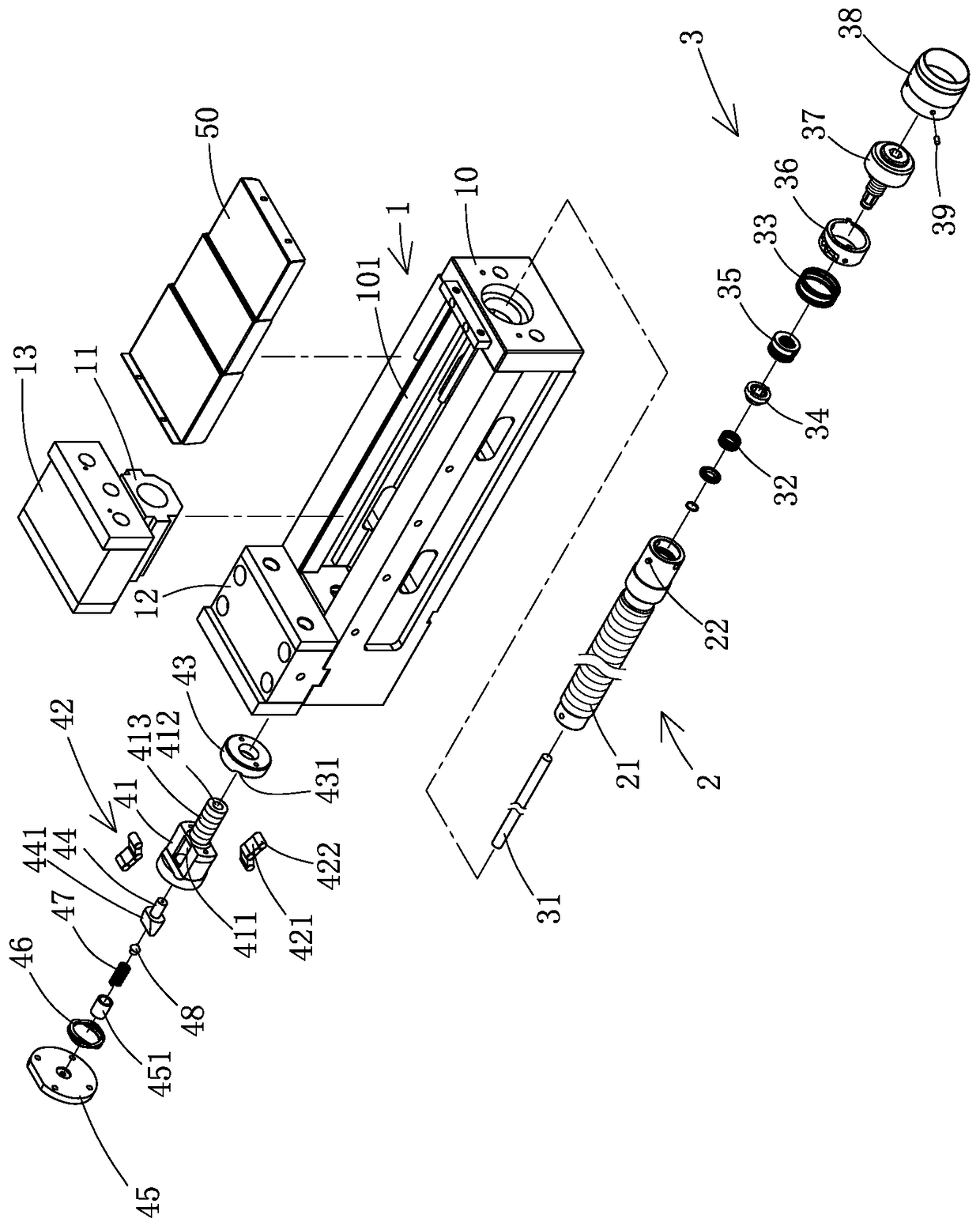

Double-clip force multiplying type jaw vice structure

Owner:HOMGE MACHINERY IND

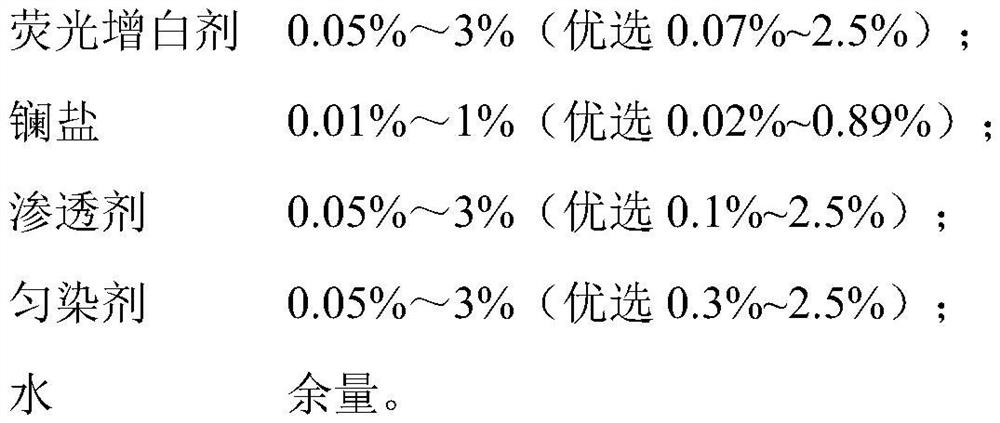

Color deepening and fixing after-finishing agent for natural colored cotton

The invention discloses a color deepening and fixing after-finishing agent for natural colored cotton. The color deepening and fixing after-finishing agent is composed of the following components in percentage by weight: 0.05%-3% of a fluorescent whitening agent; 0.01%-1% of lanthanum salt; 0.05%-3% of a penetrating agent; 0.05%-3% of a leveling agent; and the balance of water. The fluorescent whitening agent is triazinylamino stilbene. The after-finishing agent provided by the invention is easy for industrial application, and can improve the color quality of natural colored cotton products.

Owner:ZHEJIANG SCI-TECH UNIV

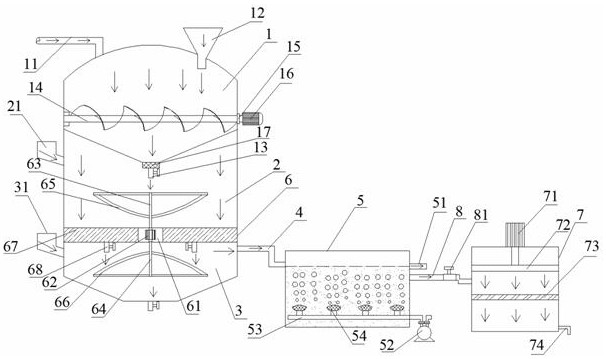

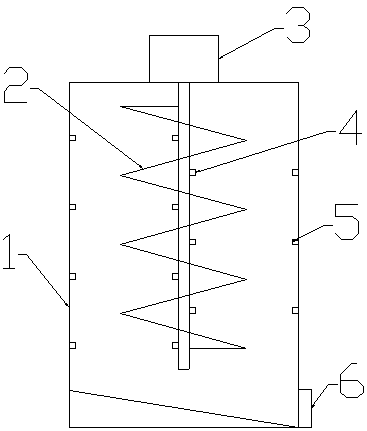

High-efficiency edible mushroom washing machine

InactiveCN108783490AHigh degree of automationIncrease productivityFood treatmentEdible mushroomConvection

The invention discloses a high-efficiency edible mushroom washing machine. The high-efficiency edible mushroom washing machine comprises a cylinder body, a spiral stirrer arranged in the cylinder body, and a motor which is coaxially connected with the upper end of the spiral stirrer, wherein a shaft of the spiral stirrer is tubular; a plurality of water sprinkler heads I are arranged on the shaftof the spiral stirrer; a stirring blade of the spiral stirrer is spiral, the outer diameter of the stirring blade is one half to two thirds of the inner diameter of the cylinder body; and a pluralityof water sprinkler heads II are arranged on the inner wall of the cylinder body. The high-efficiency edible mushroom washing machine disclosed by the invention has the beneficial effects that a multi-sprinkler-head convection spraying structure and a spiral stirring structure are designed, so that impurities on the surfaces of edible mushrooms can be quickly washed; and the high-efficiency ediblemushroom washing machine is high in automation degree, the production efficiency is greatly improved, and the high-efficiency edible mushroom washing machine is especially suitable for industrializedprocessing and treating of vegetables.

Owner:四川江中源食品有限公司

Processing method of sauce with scallion fragrance

The invention discloses a processing method of sauce with scallion fragrance. The processing method comprises the steps of pretreating raw materials and frying the raw materials. Lean sandwich meat, scallion, onion and shallot are adopted as main materials. The freshness and the fragrance of the pork are retained to a greatest extent by a special frying process, the fragrance of the scallion is strong and layered, both the taste and the color are very good, and the fragrance of scallion materials is fully retained; the process for preparing the sauce is simple, and the repeatability is high, so that the processing method is very suitable for industrial processing.

Owner:四川锦膳食品有限公司

Aluminum craft

InactiveCN102745009AElegant colorBright GuanzeDecorative surface effectsSpecial ornamental structuresColor differenceAluminium alloy

The invention discloses an aluminum craft, the main body part and / or the lining plate part of which are / is made of aluminum or an aluminum alloy. The invention makes use of the property that the light reflectivity of aluminum is greater than that of the non-aluminum part on the craft, and makes the aluminum part and the non-aluminum part present light and color differences, thus obtaining a special artistic effect.

Owner:SNTO TECH GRP

Processing method for improving color depth and color stability of natural colored cotton

The invention discloses a processing method for improving the natural colored cotton color depth and colour and luster stability. The method comprises the steps that natural colored cotton obtained after color fixing is washed and dried; the natural colored cotton is dried, then the natural colored cotton obtained after drying is subjected to liquid ammonia treatment, and the natural colored cotton after liquid ammonia treatment is obtained; gelatin, penetrant and water are mixed to form a protein solution, then the protein solution is adjusted to reach the pH being 2.0-7.0, and a treatment solution is obtained; the natural colored cotton obtained after liquid ammonia treatment is put in the treatment solution for padding at 15-70 DEG C, so that the liquid-carrying rate of natural coloredcotton obtained after padding is 30-150%, and then cold reactor placement is conducted; the natural colored cotton after fixing treatment is obtained. By means of the method, the color of the naturalcolored cotton can become brighter, and the color is obviously deepened and become more uniform; the color fastness to washing and sunshine can be effectively improved.

Owner:ZHEJIANG SCI-TECH UNIV

Preparation method of betel-nut-flavor jerky

InactiveCN103190640BRich varietyIn line with traditional consumption habitsFood preparationBetelFood flavor

The invention relates to a preparation method of a betel-nut-flavor jerky. The method is characterized in that fragmentary livestock meat is adopted as a raw material, uniformly tumbled with seasonings such as a betel nut extract at low temperature and pickled, then dried and baked to obtain meat blocks, and betel nut bittern is applied to the surface of the meat blocks using a brush, and the meat block is naturally dried. According to the invention, a jerky production process and a betel nut production process are combined to produce the series betel-nut-flavor jerky, not only can the flavor types of jerky be enriched, but also no residue is left after the betel-nut-flavor jerky is eaten, no environment pollution occurs, and the jerky is an ideal betel nut substitute food.

Owner:HUNAN AGRICULTURAL UNIV +1

A kind of treatment method of electroless nickel plating waste liquid

ActiveCN110759540BAchieve recyclingImprove processing efficiencyCalcium/strontium/barium fluoridesWater contaminantsCalcium hydroxideSulfate

A treatment method for electroless nickel plating waste liquid, comprising: (1) adding calcium hydroxide to the electroless nickel plating waste liquid for reaction, filtering to obtain primary filtrate and filter residue 1; (2) adding calcium hydroxide to the primary filtrate, Then pass through the ozone oxidation reaction and filter to obtain the oxidation filtrate and filter residue 2; (3) Add calcium hydroxide to the oxidation filtrate for reaction and filter to obtain the standard filtrate and filter residue 3; (4) Combine filter residues 1 to 3 and add sulfuric acid The solution is leached and filtered to obtain the nickel sulfate primary filtrate and filter residue 4; (5) in the nickel sulfate primary filtrate, add sodium fluoride to react, adjust the pH value, let stand, and filter to obtain the nickel sulfate filtrate and calcium fluoride residue; ( 6) Add zirconium sulfate to the nickel sulfate filtrate to react, let it stand, and filter to obtain nickel sulfate purification solution and zirconium phosphate slag; (7) adjust the pH value of the nickel sulfate purification solution, react, filter, and serve. The method of the invention has high waste water treatment efficiency, no secondary discharge, nickel recovery, simple process and low cost, and is suitable for industrial treatment.

Owner:湖南中湘春天环保科技有限公司

Recycling treatment device for wastewater containing copper cyanide

InactiveCN105461087ASuitable for industrial processingReduce dosageMultistage water/sewage treatmentChemistryPre treatment

The invention discloses a recycling treatment device for wastewater containing copper cyanide. The recycling treatment device comprises a pretreatment system for wastewater containing copper cyanide , a first-stage membrane separation treatment system, a second-stage membrane separation treatment system and a conveying system which communicate with one another sequentially through a pipeline; and the pretreatment system for wastewater containing copper cyanide comprises a collection tank for wastewater containing copper cyanide, a raw water pump, a filter, a carbon filter, a pretreatment fine filter, an ultrafilter, a backwashing pump and a pretreatment water tank which communicate with one another sequentially through a pipeline, the first-stage membrane separation treatment system comprises a first-stage boosting pump, a first-stage fine filter, a first-stage high-pressure pump, a first-stage membrane separation device and a first-stage intermediate water tank which communicate with one another sequentially through a pipeline, the second-stage membrane separation treatment system comprises a second-stage boosting pump, a second-stage high-pressure pump and a second-stage membrane separation device which communicate with one another sequentially through a pipeline, and the conveying system comprises a recycling water tank and a conveying pump which communicate with each other sequentially through a pipeline. The recycling treatment device has the advantages that the cost is reduced, and the arrangement is reasonable.

Owner:TAIZHOU HUALONG ELECTRONICS

Crude oil pour point depressant and preparation method thereof

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

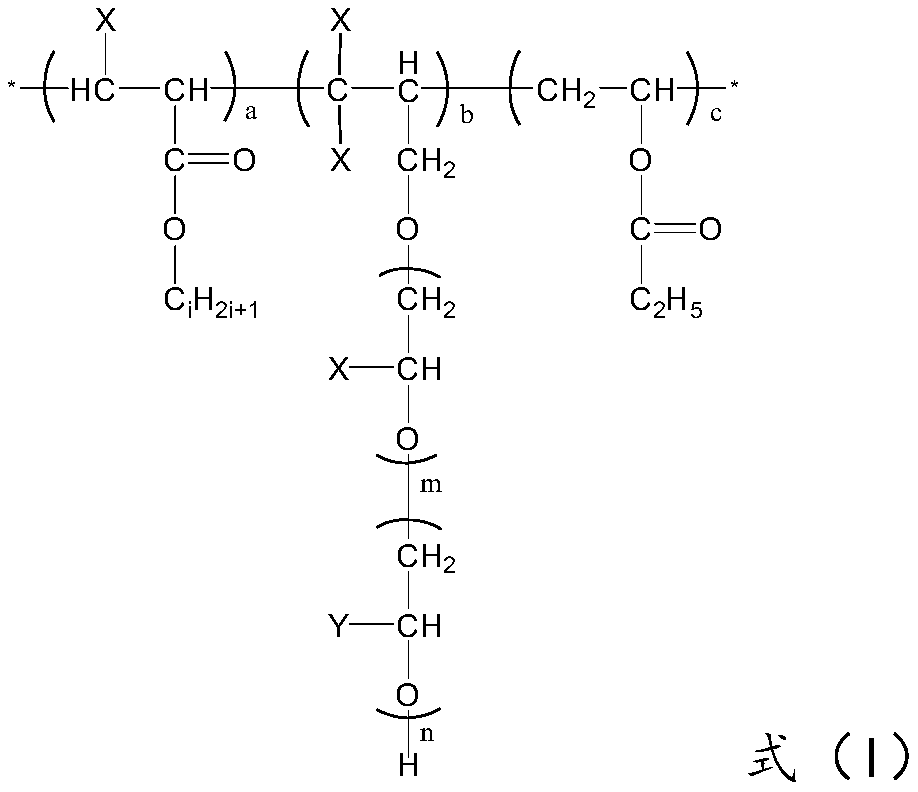

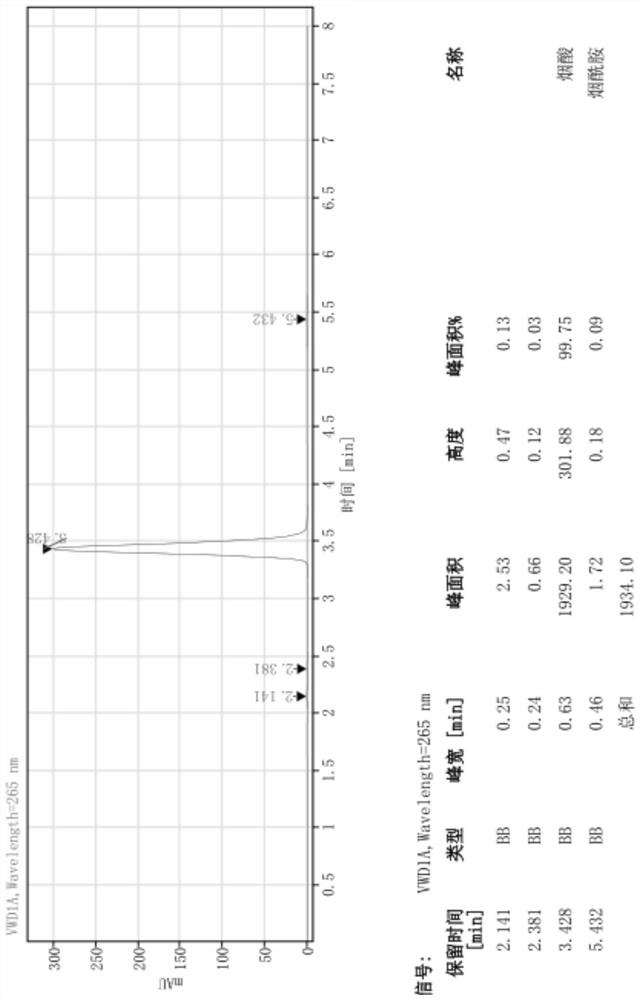

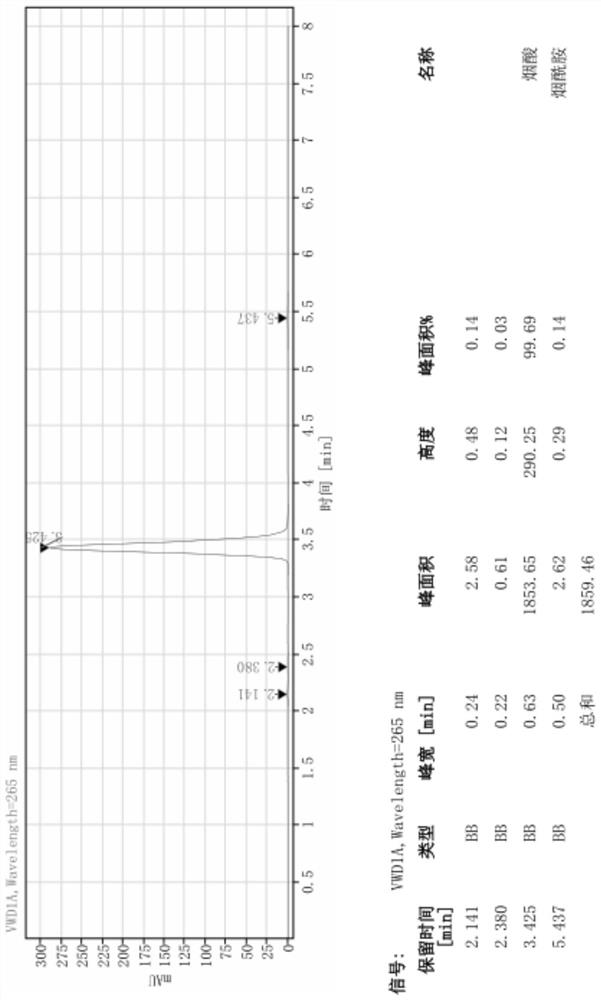

Method for recovering nicotinic acid in industrial wastewater

PendingCN114456106AReduce Niacin LossHigh recovery rateOrganic chemistryActivated carbonAcidum Nicotinicum

The invention discloses a method for recovering nicotinic acid in industrial wastewater, which comprises the following steps: concentrating nicotinic acid wastewater until the content of nicotinic acid is 100-250g / L, directly adjusting the pH value to 3.0-4.0, directly adding activated carbon, adding a certain amount of solvent for dissolving, heating and boiling, carrying out suction filtration while hot, standing the filtrate to room temperature, carrying out suction filtration again on the filtrate, washing the filter cake with water to obtain a wet product, and carrying out vacuum drying at 70-100 DEG C under-0.08 mpa-0. 10 mpa to obtain the nicotinic acid. The high-purity nicotinic acid is obtained. The method provided by the invention solves the problems of complex process conditions, low quality of recovered nicotinic acid, low recovery rate, too high wastewater treatment cost and the like in the prior art.

Owner:ANHUI RUIBANG BIOLOGICAL SCI & TECH CO LTD

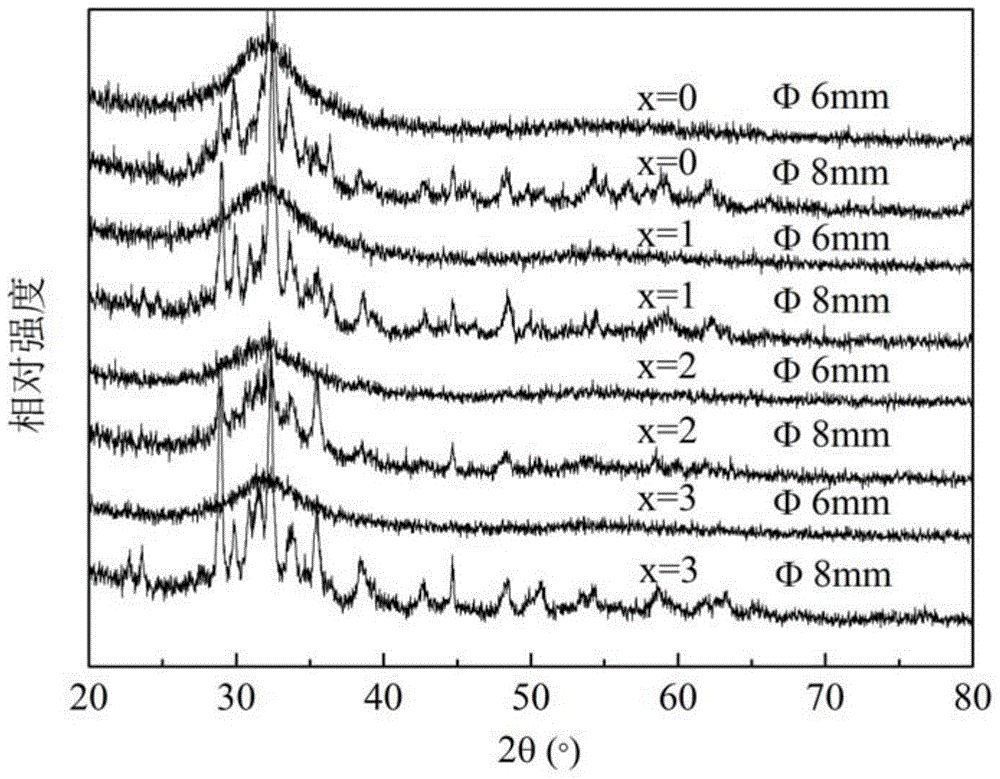

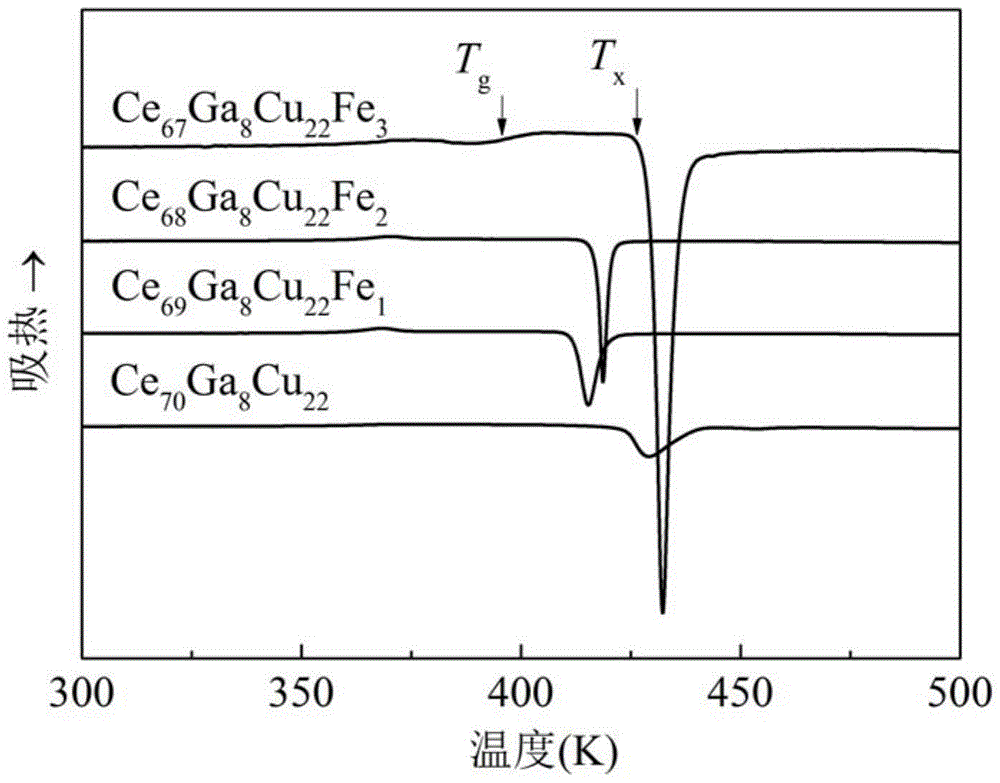

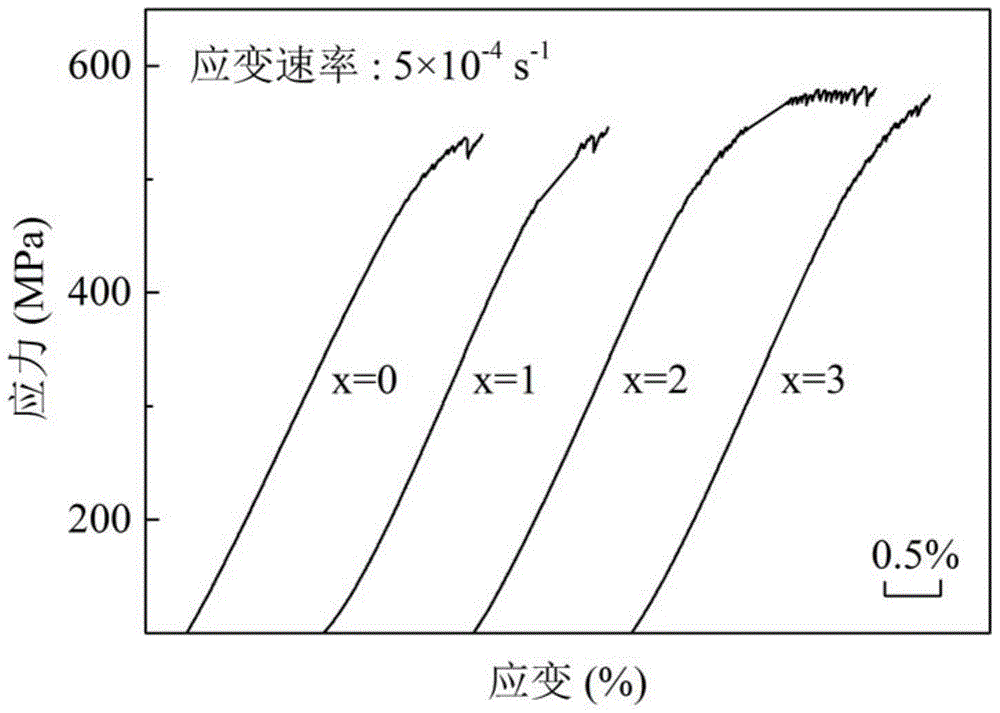

A method for improving the mechanical properties of ce‑ga‑cu bulk amorphous alloys

ActiveCN105112818BImprove mechanical propertiesExcellent vitrification abilityHigh fractureRoom temperature

The invention discloses a method for improving the mechanical property of a Ce-Ga-Cu series bulk amorphous alloy. The method is characterized by comprising the step of adding a microelement Fe into the Ce-Ga-Cu series bulk amorphous alloy to form a Ce-Ga-Cu-Fe series bulk amorphous alloy. The structural formula of the Ce-Ga-Cu-Fe series bulk amorphous alloy is Ce70-xGa8Cu22Fex, wherein x is 1, 2 or 3. Compared with the corresponding Ce-Ga-Cu series bulk amorphous alloy, the Ce-Ga-Cu-Fe series bulk amorphous alloy has the advantages that the rigidity, fracture strength and plastic deformation capability are improved to a certain extent when the high thermal stability and low glass-transition temperature are kept; when x is 2, a bar made of the Ce-Ga-Cu-Fe series bulk amorphous alloy has not only the highest fracture strength and microhardness, but also about 1% compressive plasticity at room temperature. Therefore, application of a Ce-based amorphous alloy as a functional material is facilitated.

Owner:HEFEI UNIV OF TECH

A kind of treatment method of nitro bamboo cellulose washing wastewater

ActiveCN112093960BEasy to handleAchieve recyclingWater treatment parameter controlMultistage water/sewage treatmentCelluloseSewage discharge

The invention relates to a treatment method for nitrated bamboo cellulose washing wastewater, belonging to the technical field of environmental protection. Move the nitrocellulose cellulose washing wastewater to container A for stirring and inject the nitrocellulose cellulose alkali boiling wastewater; observe after heating and stirring the container A, if the pH value is lower than 7, stir and add the nitrocellulose cellulose alkali boiling wastewater, When the pH value is 7-8, stop adding liquid M; move the liquid M to the vacuum evaporation container B to stir and vacuumize to raise the temperature, and collect the liquid X at this time; after 2 to 5 minutes, collect the liquid Y at this time, Stop when the remaining liquid in the vacuum evaporation vessel B is 5-10% of the initial total amount, the remaining liquid Z; liquid X is used for washing nitrocellulose; liquid Y is used for alkali boiling of nitrocellulose; liquid Z is recovered Utilization; the nitrocellulose washing wastewater has been treated. The treatment method provided by the invention can realize the recycling of the nitrated bamboo cellulose washing waste water, and effectively solve the problem of sewage discharge in the preparation process of the nitrated bamboo cellulose.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

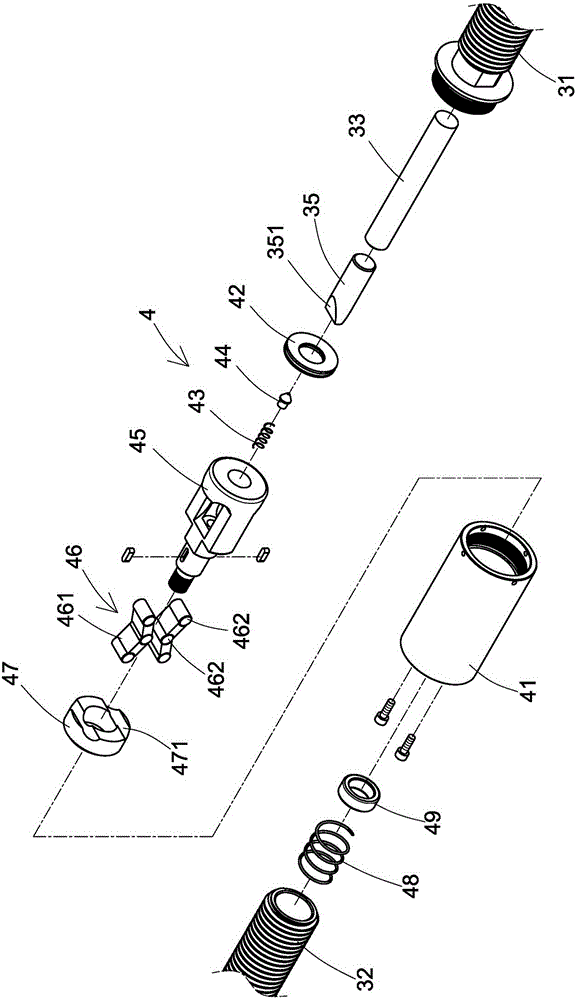

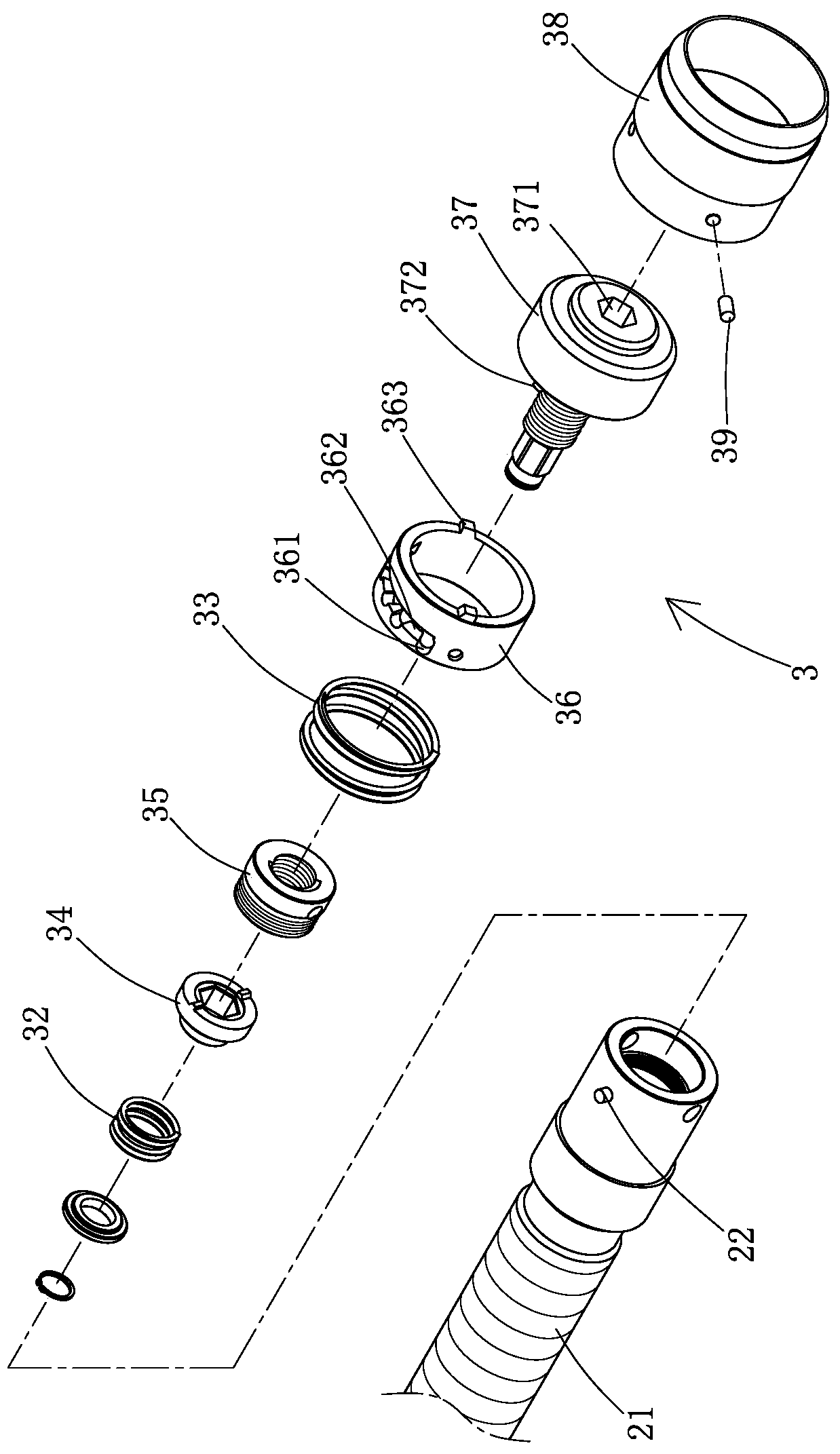

Pressure-adjusting structure for double-force-type vice

The invention discloses a pressure-adjusting structure for a double-force-type vice. The pressure-adjusting structure is composed of a vice unit, a transmission unit, an adjusting unit and a double-force unit. A push rod of the adjusting unit is arranged in a guide screw in a penetrating mode, a thread sleeve is arranged at the end of the guide screw in a threaded mode, and thus a second elastic element pushes against a pressing block; a clutch ring is arranged on the periphery of the guide screw in a sleeving mode, and provided with a plurality of axial adjusting grooves with different lengths, and a radial sliding oblique groove is arranged among the axial adjusting grooves in a connected mode. The axial adjusting grooves allow an embossment of the guide screw to move relatively, a driving tube is arranged in the thread sleeve in a threaded mode, and the end of the driving tube pushes against the push rod. An adjusting ring is fixedly connected with the clutch ring through a bolt soas to be integrally linked with the clutch ring, and thus the pressure-adjusting structure can adjust of the pressure increasing amount in a multi-stage mode and easily slides into the axial adjustinggrooves, and operation is simple, easy and effortless.

Owner:HOMGE MACHINERY IND

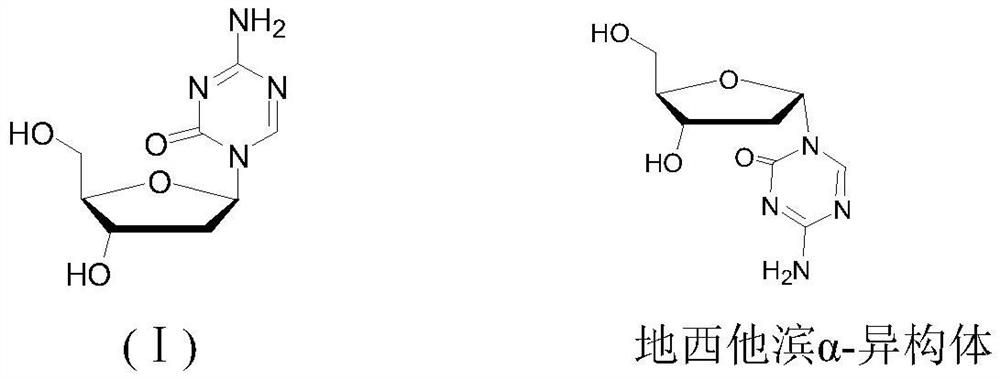

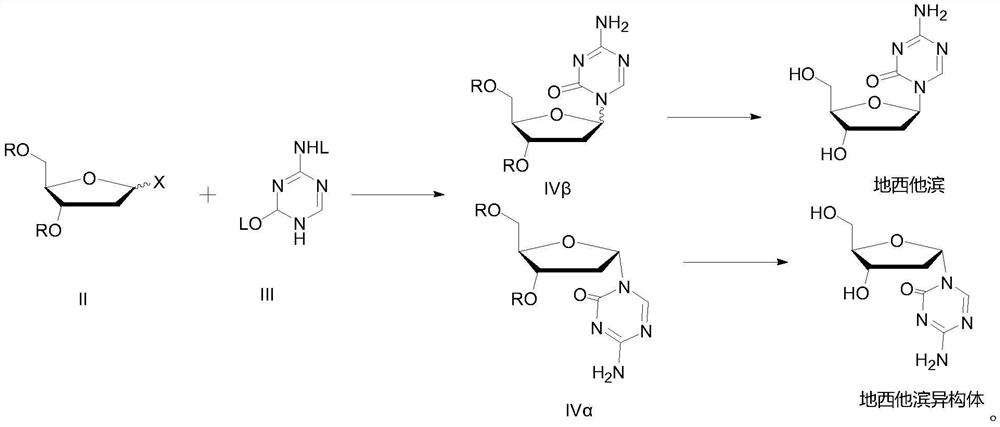

Separation method of decitabine and alpha-type isomer

PendingCN114644667AAchieve recyclingReduce yield lossSugar derivativesSugar derivatives preparationPharmaceutical drugMedicinal chemistry

The invention belongs to the technical field of medicinal chemistry, and particularly provides a method for separating decitabine and an alpha isomer, in particular to a method for separating and purifying a decitabine recovery mother solution with high content of the alpha isomer, and the high-purity alpha isomer and decitabine can be obtained only by sequential splitting through control of a crystallization process. According to the method, the decitabine mother liquor is recycled, the yield loss of decitabine is reduced, and the method is simple, reliable and suitable for industrial treatment of the decitabine mother liquor.

Owner:LUNAN PHARMA GROUP CORPORATION

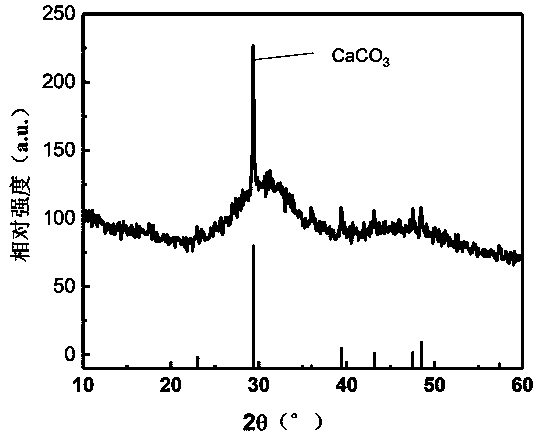

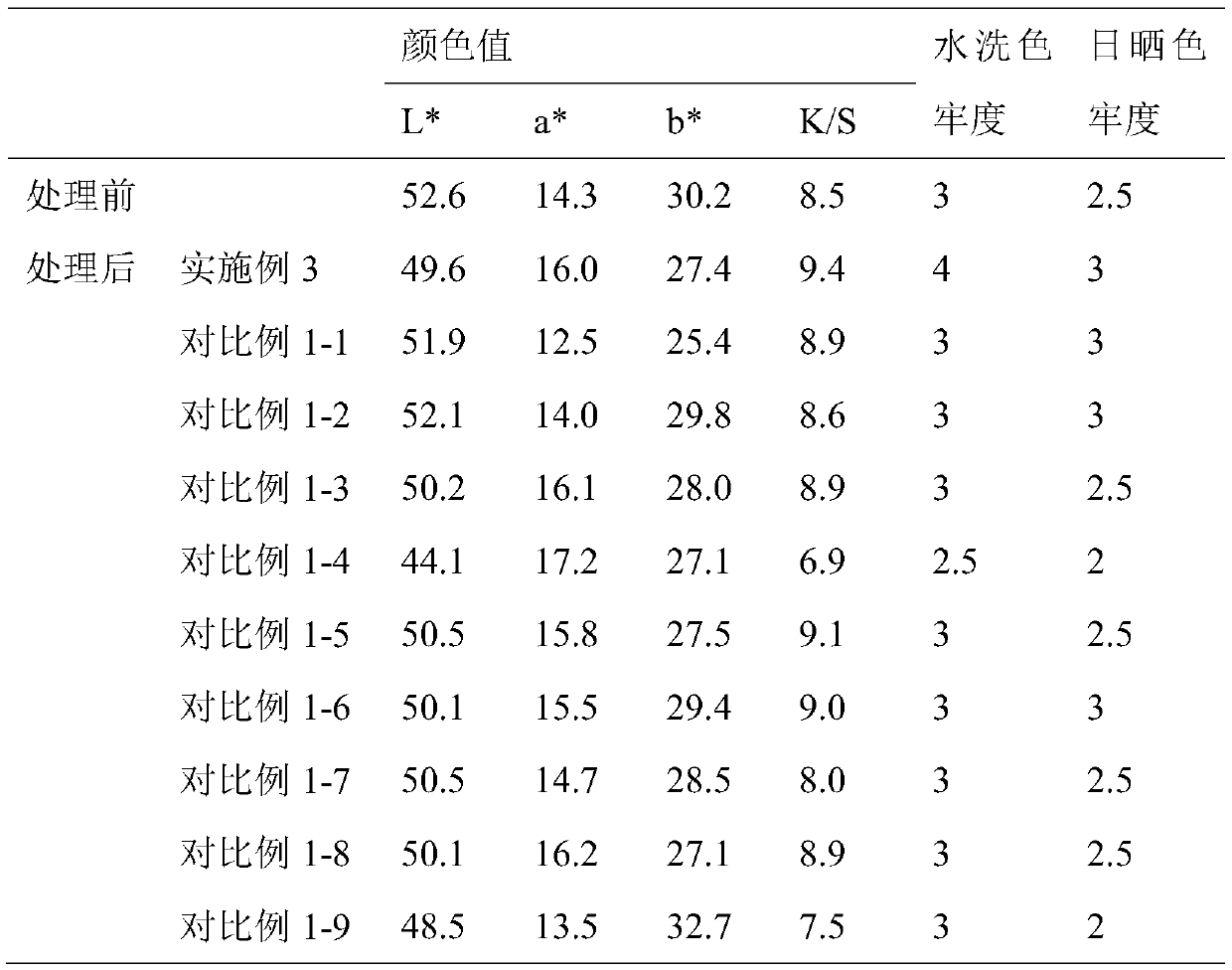

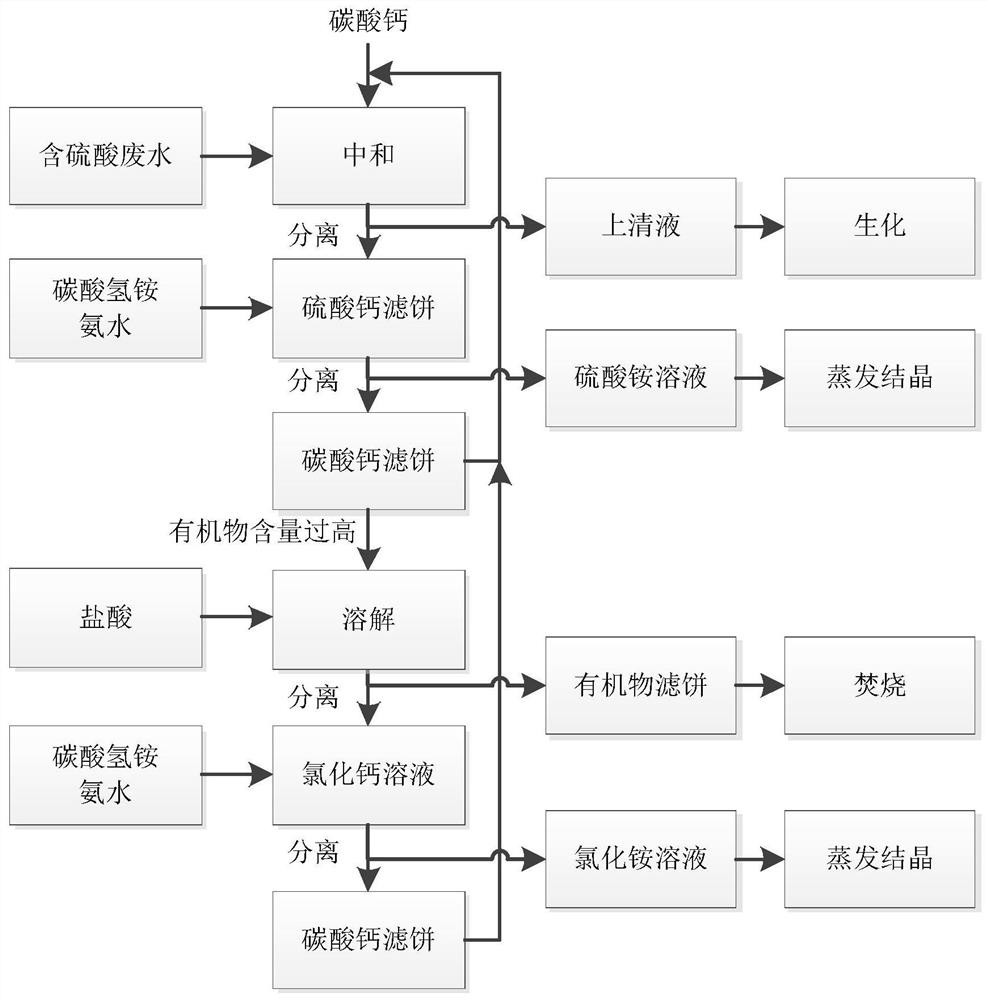

Treatment method for dye wastewater

ActiveCN113666388AEfficient treatment methodAvoid intoleranceCalcium/strontium/barium carbonatesWater contaminantsAmmoniacal nitrogenEnvironmental engineering

The invention provides a treatment method for dye wastewater. The dye wastewater contains sulfuric acid. The treatment method comprises the following steps of: 1, neutralizing the dye wastewater by using calcium carbonate, and separating to obtain a first solid product and a first clear liquid; and 2, treating the first solid product by using ammonium bicarbonate, and carrying out solid-liquid separation to obtain a second solid product containing calcium carbonate and a second clear liquid. With the treatment method for the dye wastewater disclosed by the invention adopted, the problem of biochemical bacteria intolerance caused by over-high salt content and over-high ammonia nitrogen in wastewater during biochemical treatment is avoided; toxic and harmful organic matters in the wastewater are subjected to biochemical treatment and organic solid waste incineration, and the treatment method is simple and thorough; obtained ammonium sulfate and ammonium chloride have few organic matter residues and high quality; and except the organic solid wastes, no other hazardous wastes are generated.

Owner:ZHEJIANG RUNTU +1

Method for treating nitrated bamboo cellulose soda boiling wastewater

InactiveCN112390448AEasy to handleAchieve recyclingWater treatment parameter controlMultistage water/sewage treatmentCellulosePulp and paper industry

The invention relates to a method for treating nitrated bamboo cellulose soda boiling wastewater, and belongs to the technical field of environmental protection. The method comprises the steps: transferring the nitrated bamboo cellulose soda boiling wastewater into a container A, stirring, injecting nitrated bamboo cellulose washing wastewater, and stopping injection when the pH value is 7-8; heating and stirring the container A, if the pH value is higher than 7, supplementing nitrified bamboo cellulose washing wastewater, and stopping supplementing when the pH value is 7-8 so as to obtain toobtain liquid M; transferring the liquid M into a vacuum evaporation container B, stirring, vacuumizing, heating, and collecting liquid X; after 2-5 minutes, collecting liquid Y, when the residual liquid accounts for 5-10% of the initial total amount, stopping the operation so that the residual liquid is liquid Z; washing the nitrified bamboo cellulose by using the liquid X; using the liquid Y forsoda boiling of nitrified bamboo cellulose; recycling the liquid Z; and finishing the treatment of the nitrified bamboo cellulose washing wastewater. According to the treatment method provided by theinvention, cyclic utilization of washing and soda boiling of the nitrified bamboo cellulose can be realized, and the problem of sewage discharge in the preparation process of the nitrified bamboo cellulose is effectively solved.

Owner:江西吉润花炮新材料科技有限公司

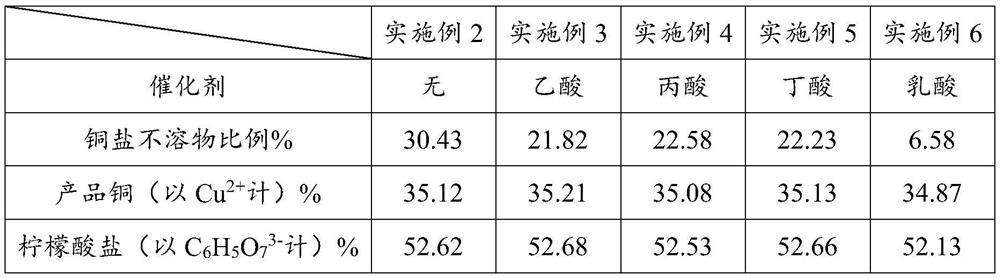

Preparation method of high-purity citric acid chelated copper

PendingCN111777502AAvoid impuritiesShort reaction timeOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystCu2 ions

The invention discloses a preparation method of high-purity citric acid chelated copper, and belongs to the field of preparation of trace element nutritional agents. The preparation method comprises the following steps: adding a formic acid catalyst into a reaction kettle according to a molar ratio of citric acid to formic acid of 1: (0.005-0.05); adding a copper salt into a reaction kettle at normal temperature, wherein the amount ratio of citric acid to copper ions in the copper salt is 1: 1.8-2.2, stirring and reacting citric acid and copper ions in the copper salt for 25-35 minutes, filtering, putting filtrate into the reaction kettle, heating to 45-55 DEG C, stirring and reacting for 25 minutes, reacting to generate citric acid chelated copper, and dehydrating to obtain citric acid chelated copper crystals. According to the invention, the formic acid is used as a catalyst; a product obtained by combining citric acid and copper ions is easily dissolved in water, copper formate is also easily dissolved in water, insoluble impurities such as lead and mercury in the raw materials can be removed through filtration, meanwhile, the situation that the product is impure, the reaction time is short and the reaction temperature is low (45-55 DEG C) due to the fact that citric acid chelated copper is generated through direct high-temperature reaction to coat the unreacted raw materials is avoided, and energy saving and environmental protection can be better realized.

Owner:GUANGHAN LONGDA FEED

A kind of treatment method and treatment system of nitrochlorobenzene production wastewater

InactiveCN103951101BImprove processing efficiencyLow running costMultistage water/sewage treatmentChlorobenzeneFiltration

A treatment method and a treatment system for nitrochlorobenzene production waste water. The method comprises the following steps: pumping nitrochlorobenzene production waste water into an adjustment pool, adjusting the pH value to allow the waste water to be acidic, then allowing the waste water to enter an oxidation pool, adding oxidizing agents of sodium hypochlorite, calcium hypochlorite or hypochloric acid for chemical oxidation treatment, discharging the effluent from the oxidation pool into a neutralization pool, adjusting the pH value to allow the effluent to be neutral, discharging the effluent from the neutralization pool into a coagulation pool, adding coagulants of one or more than one of polyaluminium chloride, polyferric chloride, and polyacrylamide for a coagulation reaction, discharging the effluent from the coagulation pool into a sedimentation pool, allowing a supernatant obtained by sedimentation and separation in the sedimentation pool to overflow into a clean water pool, discharging the clean water that reaches the standard, concentrating and filtering sedimentated sludge at the bottom of the sedimentation pool for safety treatment, and discharging waste liquid generated during the concentration and filtration process into the adjustment pool for re-treatment. According to the invention, the removal rate of nitrochlorobenzene and other nitrobenzene compounds in effluent of the nitrochlorobenzene production waste water treated by the method of the invention is up to 99%, and the method of the invention has the advantages of high treatment efficiency, low operation cost, no secondary pollution, and the like.

Owner:LUOYANG INST OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com