A kind of treatment method of electroless nickel plating waste liquid

A technology of electroless nickel plating and treatment methods, applied in chemical instruments and methods, oxidized water/sewage treatment, inorganic chemistry, etc., can solve the problems of high odor of sodium sulfide, small particle size of nickel sulfide, poor treatment effect, etc., and achieve treatment efficiency High, simple process, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

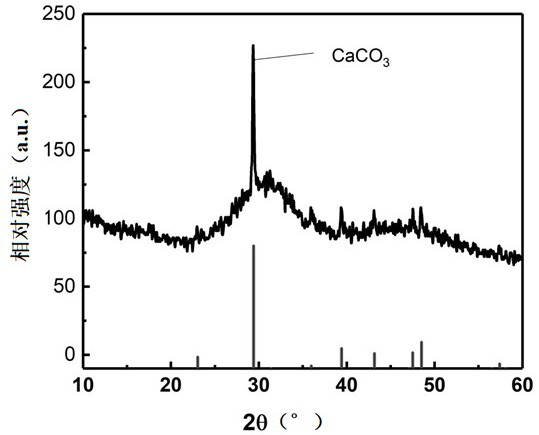

Image

Examples

Embodiment 1

[0065] (1) Put 100L of electroless nickel plating waste liquid in the reactor, add 200g of calcium hydroxide, stir and react for 30min at 20°C and pH value of 12.5, and filter to obtain the primary filtrate and 43.1g of filter residue 1;

[0066] (2) In the initial filtrate obtained in step (1), first add 1.8kg of calcium hydroxide, then pass through ozone at a rate of 1200mg / min, and at a pH value of 12.5, perform an oxidation reaction for 6 hours, filter, and obtain the oxidized filtrate and 3.8kg filter residue 2;

[0067] (3) Add 100g of calcium hydroxide to the oxidation filtrate obtained in step (2), conduct a deep phosphorus removal reaction at 20°C for 30 minutes, and filter to obtain the standard filtrate and 98.65g of filter residue 3;

[0068] (4) Combine filter residues 1 to 3 obtained in steps (1) to (3) (the total mass is 3.94175 kg), add them to 9.5 L of sulfuric acid solution with a concentration of 400 g / L, stir and leach at 30 ° C for 1 h, until After the en...

Embodiment 2

[0078] (1) Put 100L of electroless nickel plating waste liquid in the reactor, add 250g of calcium hydroxide, stir and react for 40min at 25°C and pH value of 12.5, filter to obtain primary filtrate and 91.3g of filter residue 1;

[0079] (2) In the primary filtrate obtained in step (1), first add 2kg of calcium hydroxide, and then pass through ozone at a rate of 1300mg / min. At a pH value of 12.5, the oxidation reaction is 7h, filtered, and the oxidized filtrate and 3.9 kg filter residue 2;

[0080] (3) Add 125g of calcium hydroxide to the oxidation filtrate obtained in step (2), conduct a deep phosphorus removal reaction at 25°C for 40 minutes, and filter to obtain the standard filtrate and 115.74g of filter residue 3;

[0081] (4) Combine filter residues 1 to 3 obtained in steps (1) to (3) (the total mass is 4.10704kg), add them to 10.5L of sulfuric acid solution with a concentration of 450g / L, stir and leach at 35°C for 1.5h, After the pH value at the end point is 1.5, fil...

Embodiment 3

[0091] (1) Put 100L of electroless nickel plating waste liquid in a reactor, add 300g of calcium hydroxide, stir and react for 50min at 30°C and pH value of 12.0, and filter to obtain primary filtrate and 142.1g of filter residue 1;

[0092] (2) In the initial filtrate obtained in step (1), first add 2.2 kg of calcium hydroxide, then pass through ozone at a rate of 1400 mg / min, and at a pH value of 12.0, perform an oxidation reaction for 8 hours, filter, and obtain the oxidized filtrate and 3.97kg filter residue 2;

[0093] (3) Add 150g of calcium hydroxide to the oxidation filtrate obtained in step (2), conduct a deep phosphorus removal reaction at 30°C for 50 minutes, and filter to obtain the standard filtrate and 140.5g of filter residue 3;

[0094] (4) Combine filter residues 1 to 3 obtained in steps (1) to (3) (the total mass is 4.2526kg), add them to 10.9L of sulfuric acid solution with a concentration of 500g / L, stir and leach at 40°C for 0.5h, After the end point pH v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com