A method for improving the mechanical properties of ce‑ga‑cu bulk amorphous alloys

An amorphous alloy, ce-ga-cu technology, which is applied in the field of amorphous alloys, can solve the problems of temperature increase in the shear zone region, fracture of amorphous alloys, etc., and achieve excellent vitrification forming ability and improve mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Ce 69 Ga 8 Cu 22 Fe 1 Preparation of Bulk Amorphous Alloy

[0027] Step 1: Use Ce with a raw material purity of 98.7-98.9wt.% and Ga, Cu and Fe with a purity of not less than 99.9wt.% to prepare Ce 69 Ga 8 Cu 22 Fe 1 The alloy is then smelted in a vacuum electric arc furnace under the protection of a high-purity Ar atmosphere. In order to ensure the uniform composition of the master alloy ingot, the master alloy is stirred in the furnace with electromagnetic stirring, and the master alloy is repeatedly smelted for more than 4 times. After cooling, the master alloy ingot is obtained. ingot.

[0028] Step 2: Re-melt the master alloy ingot obtained in step 1, and use the vacuum suction casting device to suction-cast the master alloy into 6mm and 8mm cylindrical water-cooled copper molds respectively to obtain 6mm and 8mm Ce 69 Ga 8 Cu 22 Fe 1 Alloy bars.

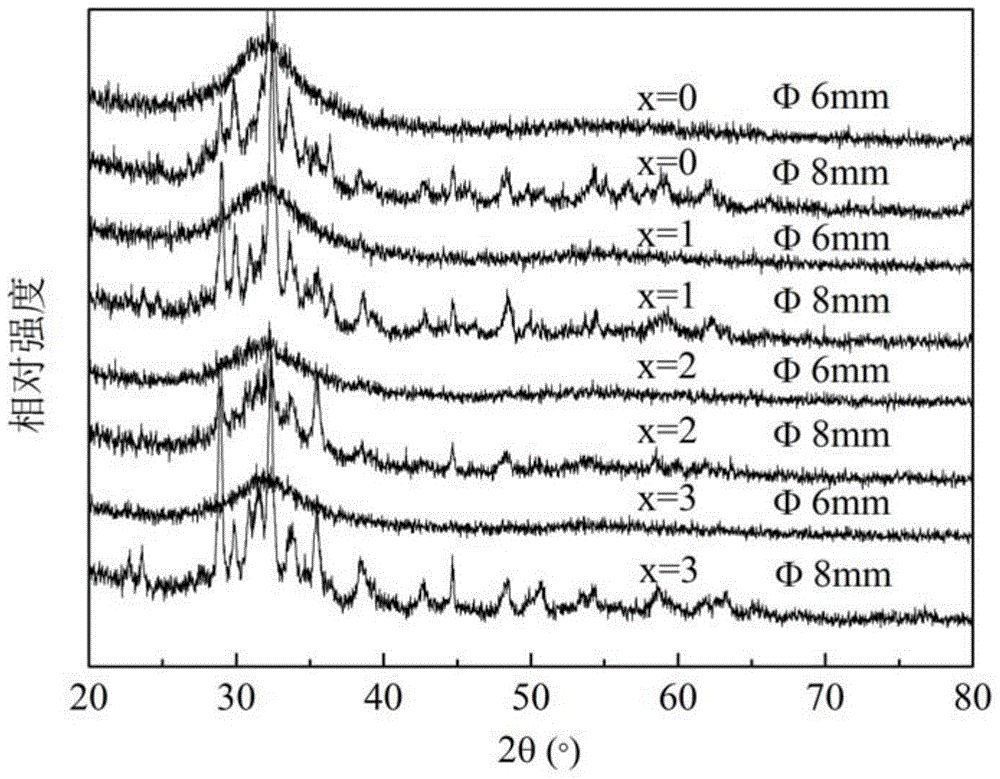

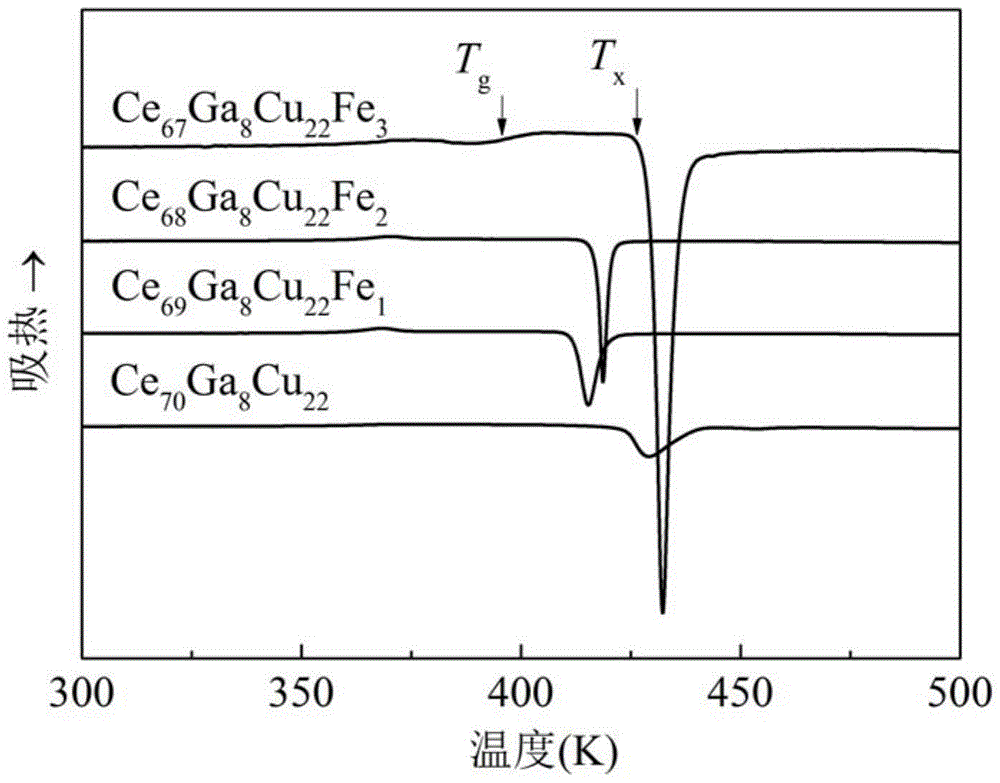

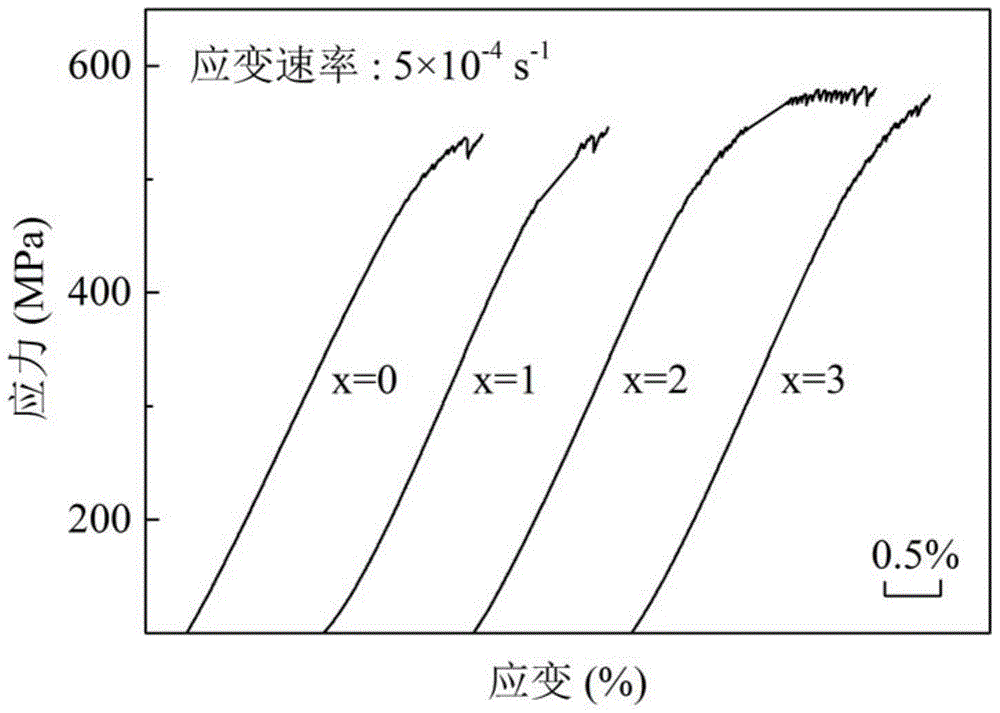

[0029] Step 3: Characterize the structure of these alloys by X-ray diffraction, the results are...

Embodiment 2

[0033] Example 2: Ce 68 Ga 8 Cu 22 Fe 2 Preparation of Bulk Amorphous Alloy

[0034]Step 1: Use Ce with a raw material purity of 98.7-98.9wt.% and Ga, Cu and Fe with a purity of not less than 99.9wt.% to prepare Ce 68 Ga 8 Cu 22 Fe 2 The alloy is then smelted in a vacuum electric arc furnace under the protection of a high-purity Ar atmosphere. In order to ensure the uniform composition of the master alloy ingot, the master alloy is stirred in the furnace with electromagnetic stirring, and the master alloy is repeatedly smelted for more than 4 times. After cooling, the master alloy ingot is obtained. ingot.

[0035] Step 2: Re-melt the master alloy ingot obtained in step 1, and use the vacuum suction casting device to suction-cast the master alloy into 6mm and 8mm cylindrical water-cooled copper molds respectively to obtain 6mm and 8mm Ce 68 Ga 8 Cu 22 Fe 2 Alloy bars.

[0036] Step 3: Characterize the structure of these alloys by X-ray diffraction, the results are ...

Embodiment 3

[0040] Example 3: Ce 67 Ga 8 Cu 22 Fe 3 Preparation of Bulk Amorphous Alloy

[0041] Step 1: Use Ce with a raw material purity of 98.7-98.9wt.% and Ga, Cu and Fe with a purity of not less than 99.9wt.% to prepare Ce 67 Ga 8 Cu 22 Fe 3 The alloy is then smelted in a vacuum electric arc furnace under the protection of a high-purity Ar atmosphere. In order to ensure the uniform composition of the master alloy ingot, the master alloy is stirred in the furnace with electromagnetic stirring, and the master alloy is repeatedly smelted for more than 4 times. After cooling, the master alloy ingot is obtained. ingot.

[0042] Step 2: Re-melt the master alloy ingot obtained in step 1, and use the vacuum suction casting device to suction-cast the master alloy into 6mm and 8mm cylindrical water-cooled copper molds respectively to obtain 6mm and 8mm Ce 67 Ga 8 Cu 22 Fe 3 Alloy bars.

[0043] Step 3: Characterize the structure of these alloys by X-ray diffraction, the results are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com