Treatment method of chemical nickel plating waste liquid

A technology of electroless nickel plating and treatment method, applied in chemical instruments and methods, oxidized water/sewage treatment, inorganic chemistry, etc. Lifespan decline, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

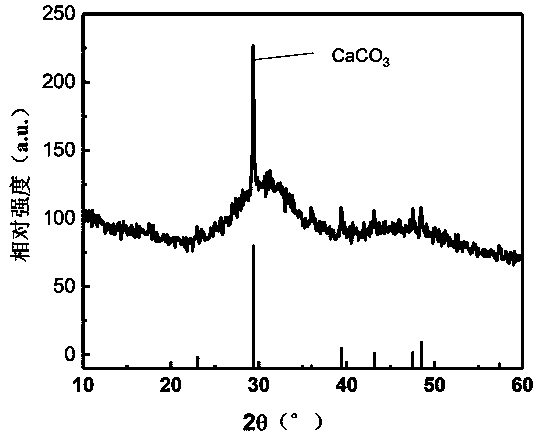

Method used

Image

Examples

Embodiment 1

[0065] (1) Put 100L of electroless nickel plating waste liquid in the reactor, add 200g of calcium hydroxide, stir and react for 30min at 20°C and pH value of 12.5, and filter to obtain the primary filtrate and 43.1g of filter residue 1;

[0066] (2) In the initial filtrate obtained in step (1), first add 1.8kg of calcium hydroxide, then pass through ozone at a rate of 1200mg / min, and at a pH value of 12.5, perform an oxidation reaction for 6 hours, filter, and obtain the oxidized filtrate and 3.8kg filter residue 2;

[0067] (3) Add 100g of calcium hydroxide to the oxidation filtrate obtained in step (2), conduct a deep phosphorus removal reaction at 20°C for 30 minutes, and filter to obtain the standard filtrate and 98.65g of filter residue 3;

[0068] (4) Combine filter residues 1 to 3 obtained in steps (1) to (3) (the total mass is 3.94175 kg), add them to 9.5 L of sulfuric acid solution with a concentration of 400 g / L, stir and leach at 30 ° C for 1 h, until After the en...

Embodiment 2

[0078] (1) Put 100L of electroless nickel plating waste liquid in the reactor, add 250g of calcium hydroxide, stir and react for 40min at 25°C and pH value of 12.5, filter to obtain primary filtrate and 91.3g of filter residue 1;

[0079] (2) In the primary filtrate obtained in step (1), first add 2kg of calcium hydroxide, and then pass through ozone at a rate of 1300mg / min. At a pH value of 12.5, the oxidation reaction is 7h, filtered, and the oxidized filtrate and 3.9 kg filter residue 2;

[0080] (3) Add 125g of calcium hydroxide to the oxidation filtrate obtained in step (2), conduct a deep phosphorus removal reaction at 25°C for 40 minutes, and filter to obtain the standard filtrate and 115.74g of filter residue 3;

[0081] (4) Combine filter residues 1 to 3 obtained in steps (1) to (3) (the total mass is 4.10704kg), add them to 10.5L of sulfuric acid solution with a concentration of 450g / L, stir and leach at 35°C for 1.5h, After the pH value at the end point is 1.5, fil...

Embodiment 3

[0091] (1) Put 100L of electroless nickel plating waste liquid in a reactor, add 300g of calcium hydroxide, stir and react for 50min at 30°C and pH value of 12.0, and filter to obtain primary filtrate and 142.1g of filter residue 1;

[0092] (2) In the initial filtrate obtained in step (1), first add 2.2 kg of calcium hydroxide, then pass through ozone at a rate of 1400 mg / min, and at a pH value of 12.0, perform an oxidation reaction for 8 hours, filter, and obtain the oxidized filtrate and 3.97kg filter residue 2;

[0093] (3) Add 150g of calcium hydroxide to the oxidation filtrate obtained in step (2), conduct a deep phosphorus removal reaction at 30°C for 50 minutes, and filter to obtain the standard filtrate and 140.5g of filter residue 3;

[0094] (4) Combine filter residues 1 to 3 obtained in steps (1) to (3) (the total mass is 4.2526kg), add them to 10.9L of sulfuric acid solution with a concentration of 500g / L, stir and leach at 40°C for 0.5h, After the end point pH v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com