Hydrofluoric acid wastewater purification treatment process

A wastewater purification and treatment process technology, applied in water/sewage treatment, biological water/sewage treatment, neutralized water/sewage treatment, etc., can solve problems such as the inability to completely remove fluoride ions and the impact of suspended solids on purified water quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

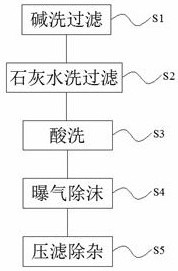

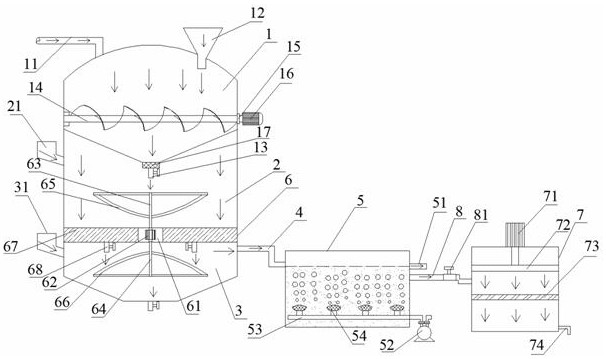

[0029] Such as Figure 1-4 As shown, the present embodiment provides a hydrofluoric acid wastewater purification treatment process, comprising the following steps:

[0030] S1. Alkali washing and filtration: pass hydrofluoric acid wastewater into the liquid inlet pipe 11 of the hydrofluoric acid wastewater purification treatment system, add 20-40wt% lye along the feed hopper 12, turn on the servo motor 16, and the servo motor 16 passes through the joint The shaft device 15 drives the spiral dragon 14 to rotate, so that the hydrofluoric acid wastewater and the lye are mixed more fully and evenly, and the hydrofluoric acid and sodium hydroxide react to form sodium fluoride, and the pH is adjusted to 6±0.5; the first filter plate 17 is used for alkali cleaning After the waste water is filtered to remove solid impurities and sodium fluoride, it flows into the lime water cleaning chamber 2 along the first regulating valve 13;

[0031] S2. Lime water washing and filtration: Lime wa...

Embodiment 2

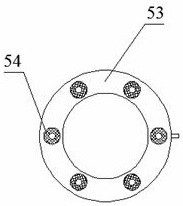

[0037] Such as Figure 1-4 As shown, the present embodiment provides a hydrofluoric acid wastewater purification treatment system, which is suitable for the hydrofluoric acid wastewater purification treatment process of Example 1, including an alkali cleaning chamber 1, a lime water cleaning chamber 2, A pickling chamber 3, the top side wall of the pickling chamber 3 is connected to the aeration chamber 5 through the first discharge pipe 4, and the side wall of the supernatant of the aeration chamber 5 is connected to the pressure filter chamber through the second discharge pipe 8 7.

[0038] The hydrofluoric acid wastewater purification treatment system of the present embodiment is provided with an alkali cleaning chamber 1, a lime water cleaning chamber 2, and an pickling chamber 3 from top to bottom, and the pickling chamber 3 and the aeration chamber 5 pass through the first discharge pipe 4 connection, the aeration chamber 5 and the pressure filter chamber 7 are connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com