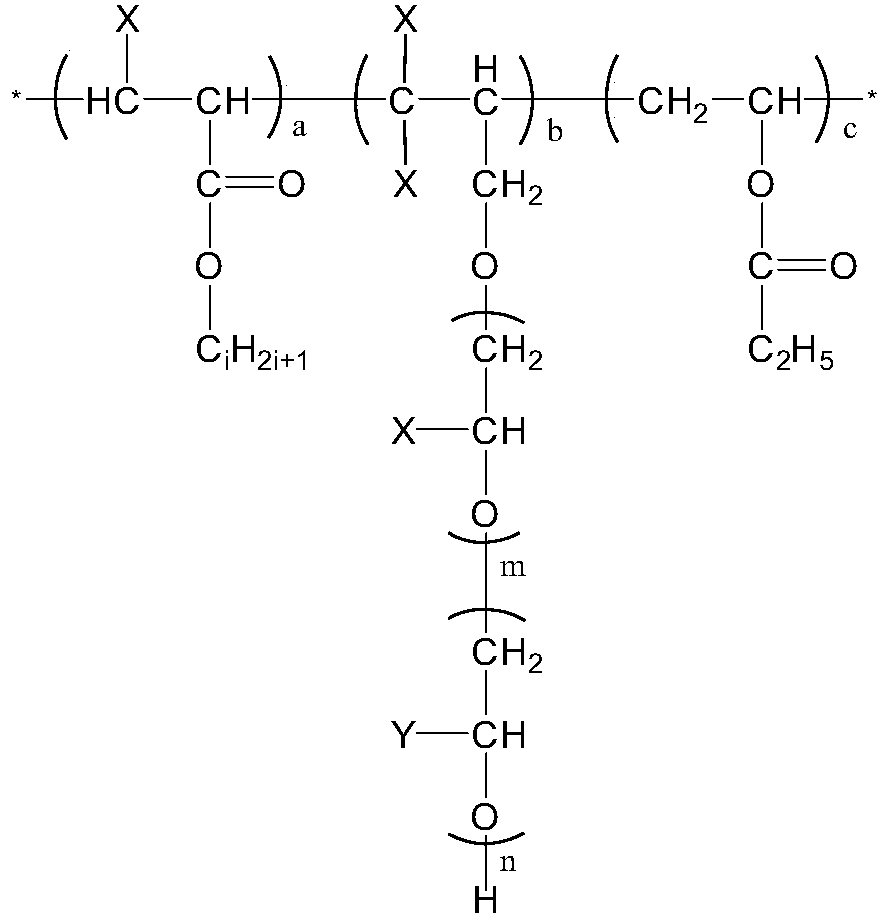

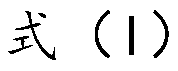

Crude oil pour point depressant and preparation method thereof

A crude oil pour point depressant and solvent technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of reducing crude oil viscosity, poor crude oil pour point depressing effect, single molecular structure, etc., to reduce crude oil viscosity, easy The effect of simple control and preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The embodiment of the present invention also provides a kind of preparation method of the crude oil pour point depressant as described in the above embodiment, comprising the following steps: the higher alcohol ester of unsaturated acid, the polyoxyethylene polyoxypropylene ether of unsaturated alcohol and Add vinyl acetate into the reaction vessel according to the set ratio, add the solvent, stir evenly, slowly raise the temperature, then add the initiator dropwise, under the protection of nitrogen, pass through at a reaction temperature of 80°C-110°C, and a reaction time of 3- A polymerization reaction occurs under the condition of 8 hours to obtain a crude oil pour point depressant.

[0031] The above-mentioned embodiment provides a kind of preparation method of crude oil pour point depressant, wherein, three kinds of monomers are produced to obtain terpolymer by direct polymerization reaction under the action of solvent, initiator, in above-mentioned preparation meth...

Embodiment 1

[0041] Preparation of Unsaturated Acid Fatty Alcohol Esters

[0042] Mix acrylic acid and lauryl alcohol at a molar ratio of 0.8:1, add 30% toluene as a solvent, then mix 1% concentrated sulfuric acid with the above raw materials, put them into a four-necked flask together, add a polymerization inhibitor, and gradually heat up to Reflux dehydration at 90°C, stop the reaction after the water output reaches the theoretical value after 3 hours of reaction, use Na 2 CO 3 The solution was washed, and then washed with water, and the layers were separated, and the organic phase was extracted to obtain lauryl acrylate, which was set aside.

[0043] Preparation of Unsaturated Alcohol Polyoxyethylene Polyoxypropylene Ether

[0044] Put 1mol of propylene alcohol into the autoclave, add NaOH as catalyst, vacuumize, N 2 Purge three times, gradually raise the temperature to 100°C, continuously feed ethylene oxide and propylene oxide, and keep the reaction pressure at 0.1MPa. After the fe...

Embodiment 2

[0050] Preparation of Unsaturated Acid Fatty Alcohol Esters

[0051] Mix methacrylic acid and cetyl alcohol in a molar ratio of 1:1, add 50% cyclohexane as a solvent, then mix 2% concentrated phosphoric acid with the above raw materials, put them into a four-necked flask together, and add a polymerization inhibitor , Gradually raise the temperature to 70°C for reflux dehydration, stop the reaction after the water output reaches the theoretical value after 4 hours of reaction, use Na 2 CO 3 The solution was washed, and then washed with water, and the layers were separated, and the organic phase was extracted to obtain cetyl methacrylate, which was set aside.

[0052] Preparation of Unsaturated Alcohol Polyoxyethylene Polyoxypropylene Ether

[0053] Put 1mol of butenol into the autoclave, add Ca(OH) 2 As a catalyst, vacuum, N 2 Purge three times, gradually raise the temperature to 110°C, continuously feed ethylene oxide and propylene oxide, and keep the reaction pressure at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com