Double-clip force multiplying type jaw vice structure

A double-clamp multi-force type, vise technology, applied in the field of vise structure, can solve the problems of insufficient clamping force of the workpiece, tool vibration, difficult for users to assemble and maintain, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

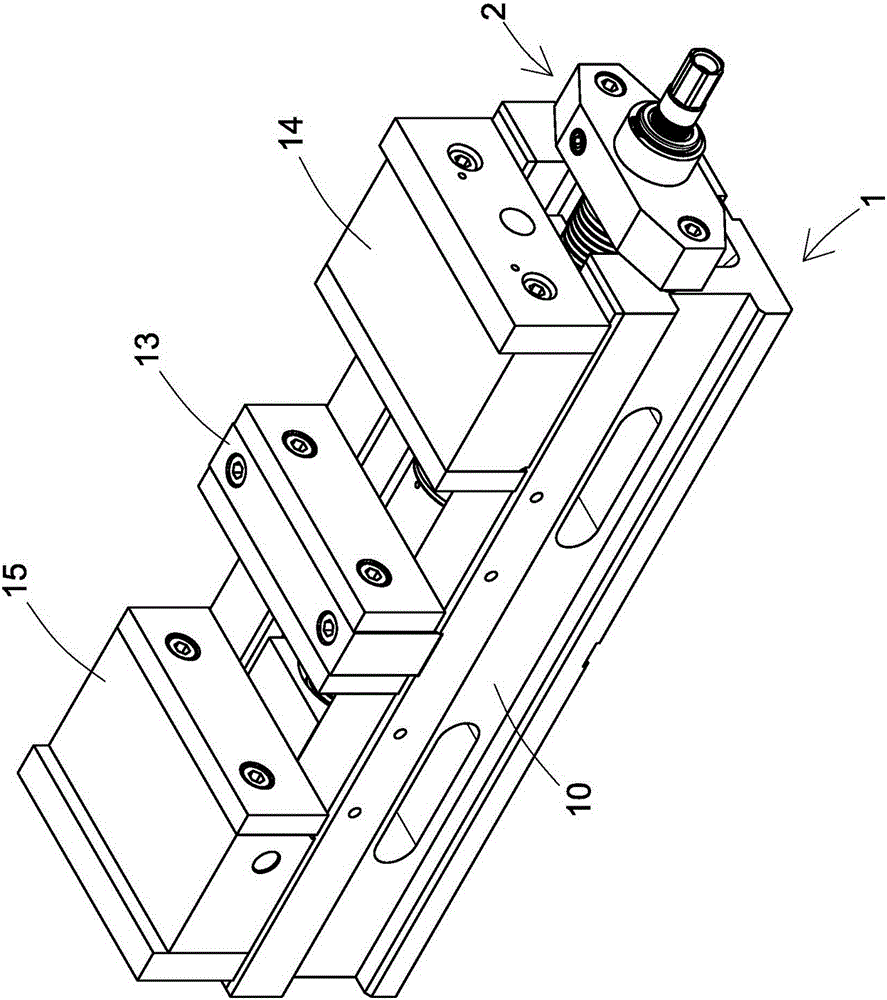

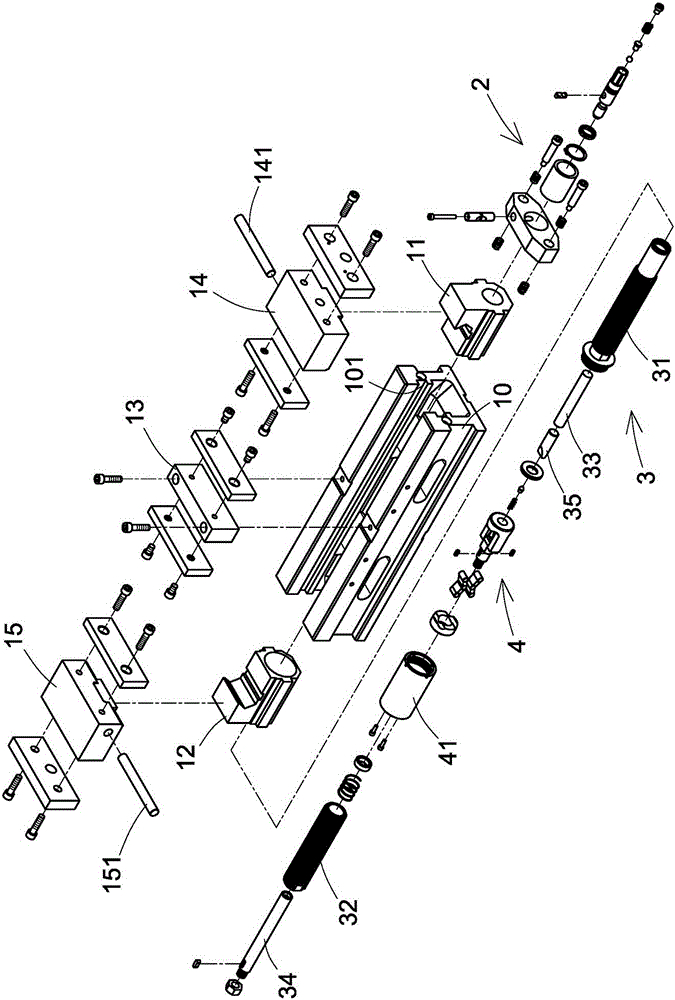

[0070] First, please refer to Figure 1 to Figure 6 Shown, the present invention is a kind of double-clamp multiplier type vise, and it comprises:

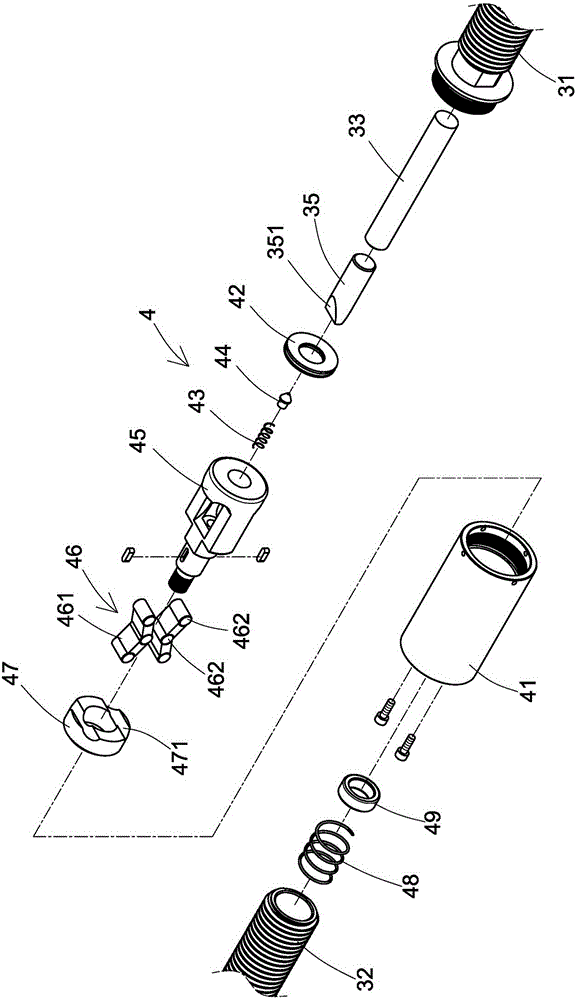

[0071] A vise unit 1, the vise unit 1 has a body 10, the body 10 is provided with a sliding groove, the opposite sides of the inner edge of the sliding groove are respectively provided with a guide rail 101, and the two guide rails 101 respectively provide a The anterior angle tooth base 11 of the inclined surface 111 and the rear angle tooth base 12 with the second pressing inclined surface 121 are slidably set, and a fixed jaw 13 is fixed at the center of the top surface of the body 10, and the top surface of the body 10 is located at the A first movable jaw 14 with a first pressure rod 141 and a second movable jaw 15 with a second pressure rod 151 are respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com