Composite gradient laminated solder preform for power electronics and manufacturing method thereof

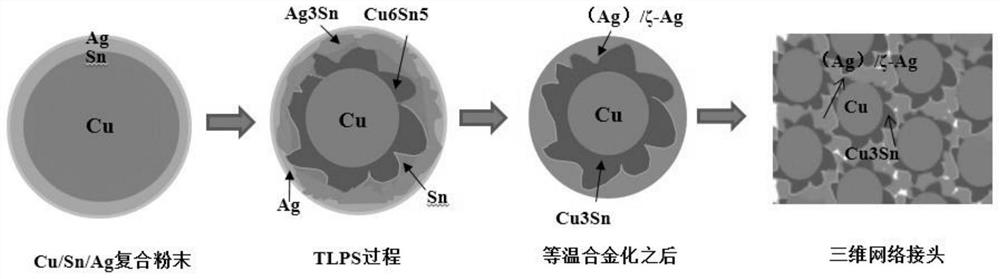

A solder preform and power electronics technology, which is applied in the field of power electronics, can solve problems such as poor mechanical properties, low reliability, and large amount of precious metals, and achieve excellent electrical and thermal conductivity, high temperature resistance and reliability, and simple preparation methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

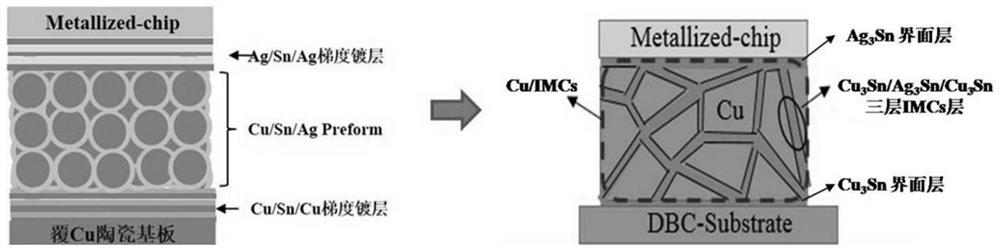

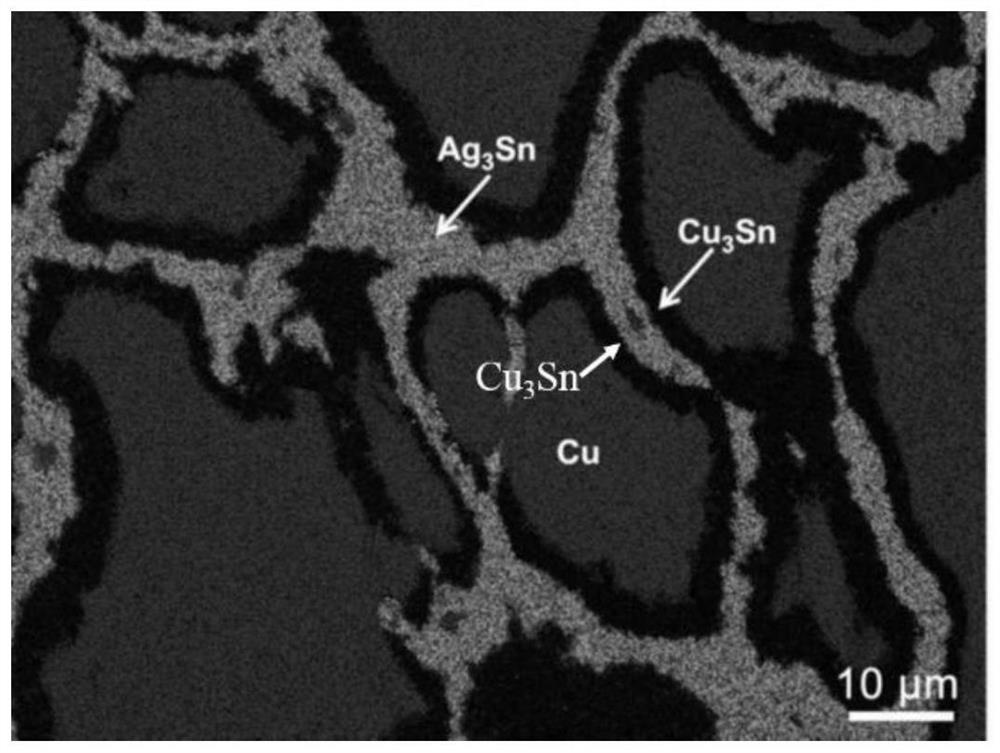

[0039] Copper powder with a particle size of 5-10 μm and 10-15 μm is used to prepare the electroplating Sn coating and the physical vapor deposition Ag coating respectively, and the particle size is graded according to the ratio of 3:2, and the graded powder is placed in a high-speed ball mill. , mechanically mixed at a rate of 100r / min for 1h to obtain a homogeneously mixed composite powder.

[0040] Weigh 0.13 g of the above-mentioned mixed powder, perform high-pressure tablet pressing on a press with a pressure of 10 MPa, and hold a constant pressure for 10 minutes to obtain a solder sheet with a thickness of 345 μm. Prepare the compound gradient coating on the upper and lower surfaces of the preform prepared above by magnetron sputtering. One side of the welding chip is a repeating structural unit of "Ag / Sn / Ag", and the side of the welding substrate is "Cu / Sn / Cu "Repeating structural units, the thickness of each structural unit gradually increases from the Preform to the d...

Embodiment 2

[0044] Copper powders with a particle size of 5-10 μm and 15-20 μm were used for electroplating Sn and sputtering Ag coatings respectively, and the particle size was graded according to the ratio of 3:1, and the graded powder was placed in a high-speed ball mill. Mix mechanically for 2 hours at a rate of 200r / min to obtain a uniformly mixed composite powder.

[0045] Weigh 0.13 g of the above-mentioned mixed powder, perform high-pressure tablet pressing on a press with a pressure of 15 MPa, and hold a constant pressure for 10 minutes to obtain a solder sheet with a thickness of 300 μm. The preform Preform prepared above was prepared by magnetron sputtering to prepare the upper and lower surface gradient composite laminated structures as "Ag / Sn / Ag"g and "Cu / Sn / Cu" respectively, and the thickness of the innermost structural unit is 600nm. The increasing thickness gradient is 120 nm, the number of repeating structural units is 10, and the total thickness is 14 μm.

[0046] The s...

Embodiment 3

[0048] Copper powders with a particle size of 5-15 μm and 15-30 μm were used for electroplating Sn and sputtering Ag coatings respectively, and the particle size was graded according to the ratio of 3:1. The graded powder was placed in a high-speed ball mill. Mix mechanically for 1 hour at a rate of 500 r / min to obtain a uniformly mixed composite powder.

[0049] Weigh 0.13 g of the above-mentioned mixed powder, perform high-pressure tablet pressing on a press with a pressure of 10 MPa, and hold a constant pressure for 5 minutes to obtain a solder sheet with a thickness of 200 μm. The Preform prepared above was prepared by magnetron sputtering to prepare the upper and lower surface gradient composite coating structures as "Ag / Sn / Ag" and "Cu / Sn / Cu" respectively, the innermost structural unit thickness is 500nm, and the incremental thickness gradient is 150nm. The number of repeating structural units is 12, and the total thickness is 15 μm.

[0050] Sinter the solder preform wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com