Treating agent and method for controlling primary carbide of high-carbon martensitic stainless steel through melt treatment

A technology of carbon martensite and treatment agent, which is applied in the field of carbide control of high-carbon martensitic stainless steel, and can solve the problems of inconspicuous aggregation and growth of carbides, inclusions, and unsuitability for clean production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

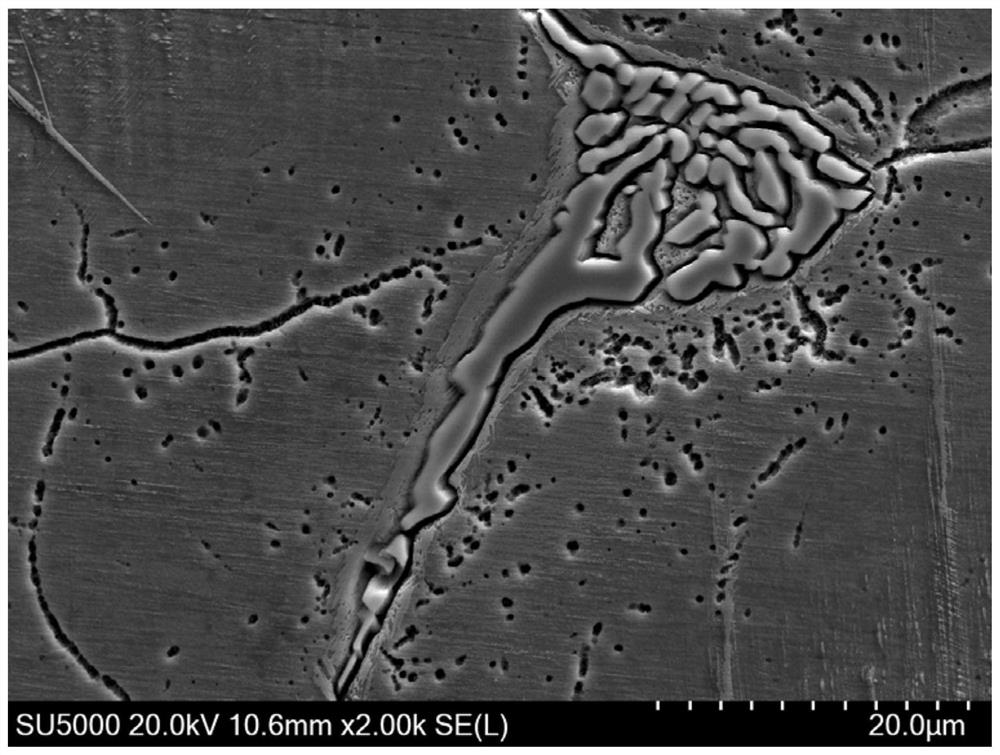

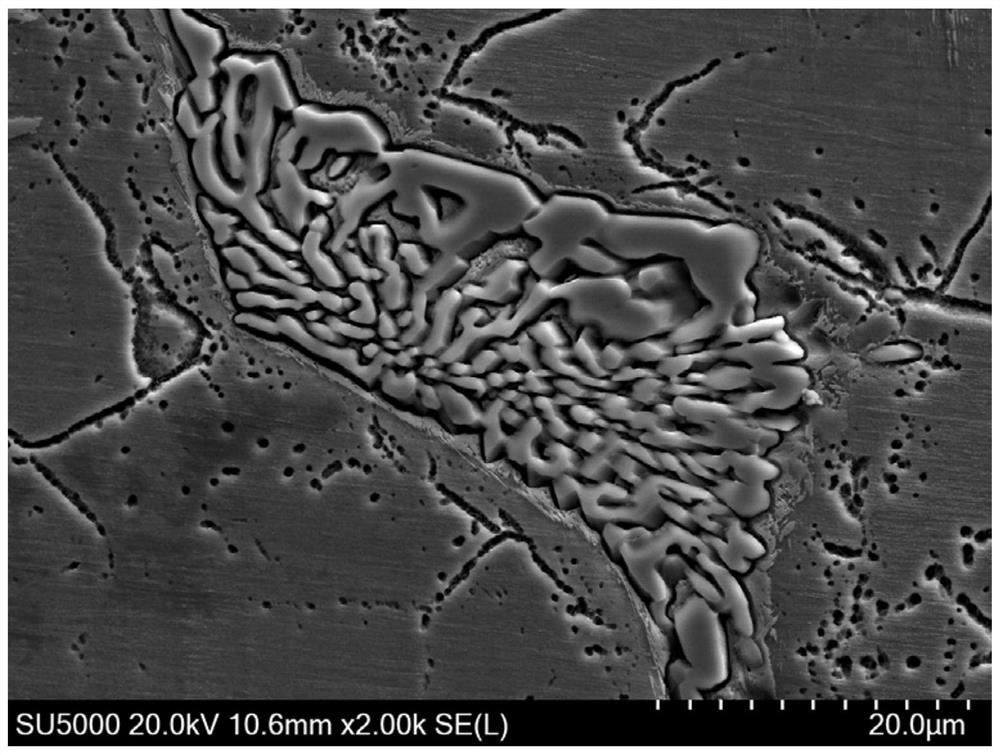

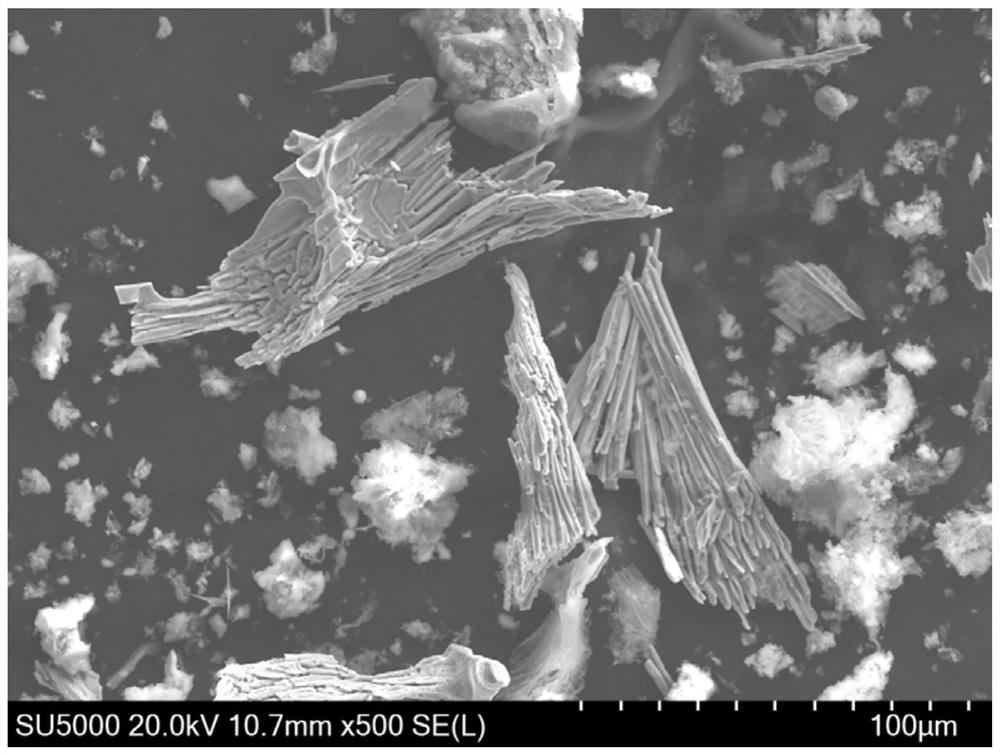

Image

Examples

Embodiment 1

[0025] Select 7Cr14 martensitic stainless steel (composition: C: 0.65% to 0.75%, Cr: 13.5 to 15.5%, Mn: 0.45 to 0.65%, Si: 0.25 to 0.45%, Mo: 0.35 to 0.45%, V: Mo: 0.35 ~0.45%), according to the method for controlling carbide of the present invention, implement the primary carbide of controlling 7Cr14 martensitic stainless steel, mainly comprise the following steps:

[0026] Using a 200kg intermediate frequency furnace to smelt 200kg molten steel in the atmosphere, taking into account the burning loss of alloy elements, the composition is controlled within the upper limit of the allowable range;

[0027] After completely melting and holding for 5 minutes, refine in the furnace. The weight percentage of each component of the refining slag system is: 30% CaO, 40% SiO 2 , 25%Al 2 o 3 , 5% MgO and other components.

[0028] After refining for 20 minutes, feed the wire and add a melt treatment agent. The composition of the melt treatment agent is: 40% rare earth ferrosilicon, 30...

Embodiment 2

[0032] Select 7Cr14 martensitic stainless steel (composition: C: 0.65% to 0.75%, Cr: 13.5 to 15.5%, Mn: 0.45 to 0.65%, Si: 0.25 to 0.45%, Mo: 0.35 to 0.45%, V: Mo: 0.35 ~0.45%), according to the method for controlling carbide of the present invention, implement the primary carbide of controlling 7Cr14 martensitic stainless steel, mainly comprise the following steps:

[0033] Using a 200kg intermediate frequency furnace to smelt 200kg molten steel in the atmosphere, taking into account the burning loss of alloy elements, the composition is controlled within the upper limit of the allowable range;

[0034] After completely melting and holding for 5 minutes, refine in the furnace. The weight percentage of each component of the refining slag system is: 10% CaO, 50% SiO 2, 25%Al 2 o 3 , 15% MgO and other components.

[0035] After refining for 20 minutes, feed the wire and add a melt treatment agent. The composition of the melt treatment agent is: 70% rare earth ferrosilicon, 20...

Embodiment 3

[0038] Select 7Cr14 martensitic stainless steel (composition: C: 0.65% to 0.75%, Cr: 13.5 to 15.5%, Mn: 0.45 to 0.65%, Si: 0.25 to 0.45%, Mo: 0.35 to 0.45%, V: Mo: 0.35 ~0.45%), according to the method for controlling carbide of the present invention, implement the primary carbide of controlling 7Cr14 martensitic stainless steel, mainly comprise the following steps:

[0039] Using a 200kg intermediate frequency furnace to smelt 200kg molten steel in the atmosphere, taking into account the burning loss of alloy elements, the composition is controlled within the upper limit of the allowable range;

[0040] After completely melting and holding for 5 minutes, refine in the furnace. The weight percentage of each component of the refining slag system is: 60% CaO, 15% SiO 2 , 10% Al 2 o 3 , 15% MgO and other components.

[0041] After refining for 20 minutes, feed the wire and add a melt treatment agent. The composition of the melt treatment agent is: 20% rare earth ferrosilicon, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com