High-performance hot work die steel and preparation method thereof

A high-performance technology for hot work die steel, applied in the field of high toughness, high heat crack resistance hot work die steel and its preparation, and high ductility, can solve the problems of high cost and long production cycle, and achieve high purity degree, inhibit the growth of austenite grains, and improve the effect of anisotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

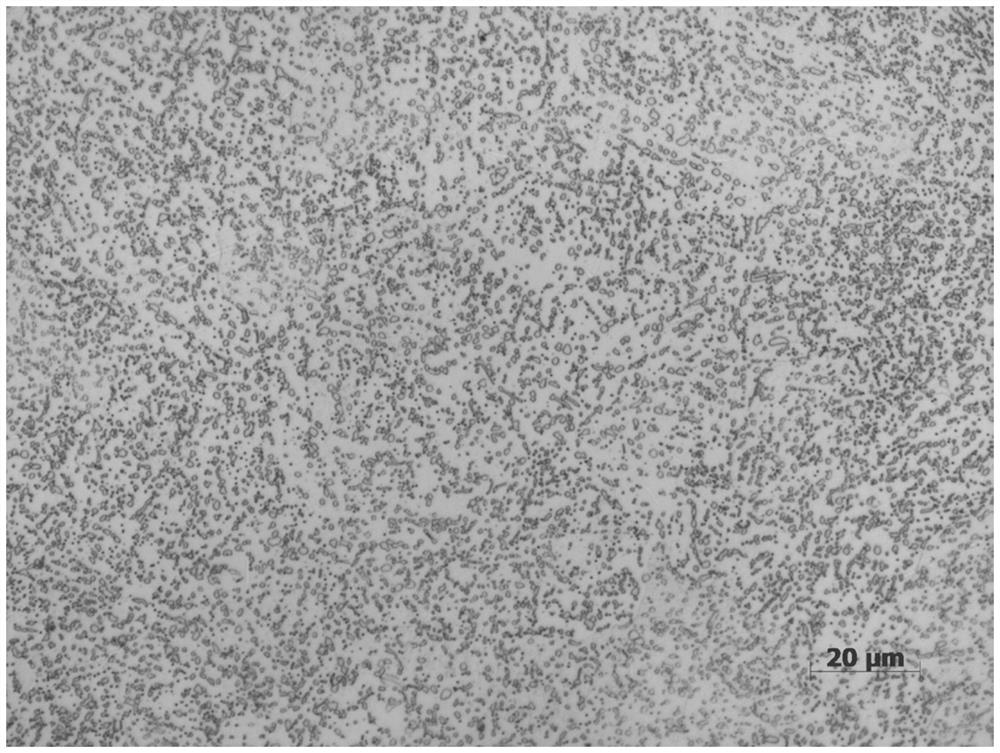

Embodiment 1

[0051] A hot work die steel basically consists of the elements in Table 1 according to the mass fraction:

[0052] Table 1

[0053]

[0054] Its preparation method, the main steps are as follows:

[0055] S1, electric furnace smelting:

[0056] According to the preparation of scrap steel and alloy materials in advance according to Table 1, scrap steel is first smelted in batches according to the smelting weight in the electric furnace, and the molten steel temperature is 1645 ℃ for oxidation and slag removal. After the slag removal, alloy materials, lime and fluorite are added to adjust the chemical composition and Dephosphorization, the tapping temperature is 1630 ℃, aluminum wire is added during the tapping process, and the aluminum wire is added at 1kg / t for deoxidation.

[0057] S2, ladle refining furnace refining:

[0058] After the electric furnace smelting, the molten steel is transferred to the ladle, hoisted to the refining furnace base, and added with slag CaO ...

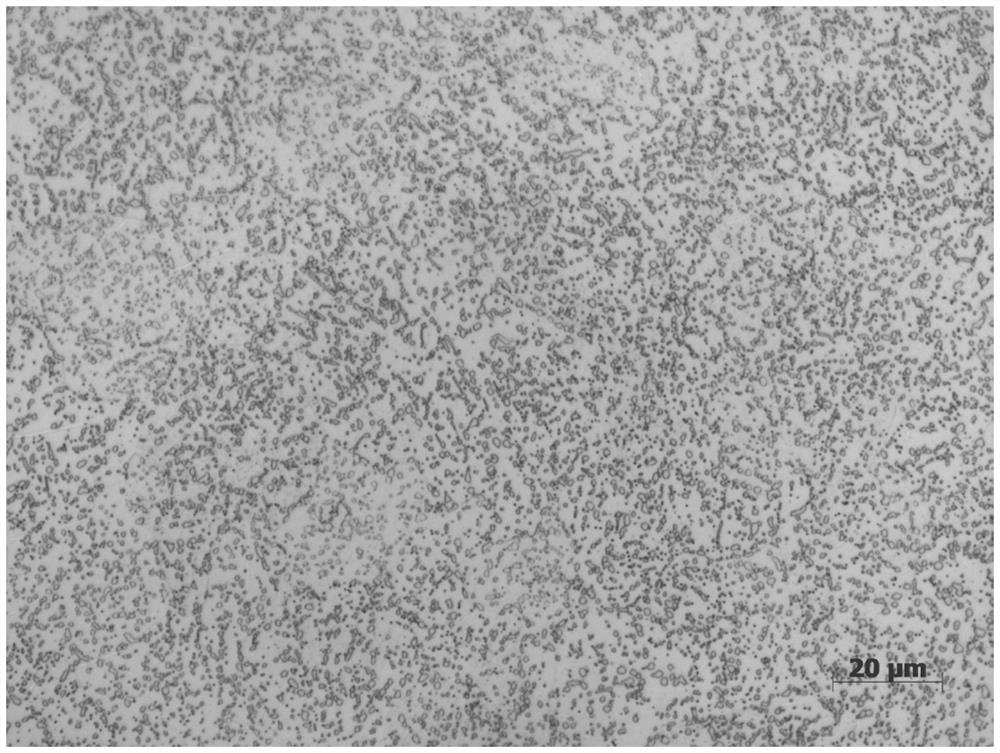

Embodiment 2

[0075] A hot work die steel, according to the mass fraction, basically consists of the elements in Table 2:

[0076] Table 2

[0077]

[0078] Its preparation method, the main steps are as follows:

[0079] S1, electric furnace smelting:

[0080] According to the preparation of scrap steel and alloy materials in advance according to Table 2, scrap steel is first smelted in batches according to the smelting weight in the electric furnace, and the molten steel temperature is 1640 ℃ to oxidize the slag. Dephosphorization, the tapping temperature is 1630 ℃, aluminum wire is added during the tapping process, and the aluminum wire is added at 1.0kg / t for deoxidation.

[0081] S2, ladle refining furnace refining:

[0082] After the electric furnace smelting, the molten steel is transferred to the ladle, hoisted to the refining furnace base, and added with slag CaO and CaF. 2 , C-Si powder is reduced to form white slag, and alloy material is added according to the actual compos...

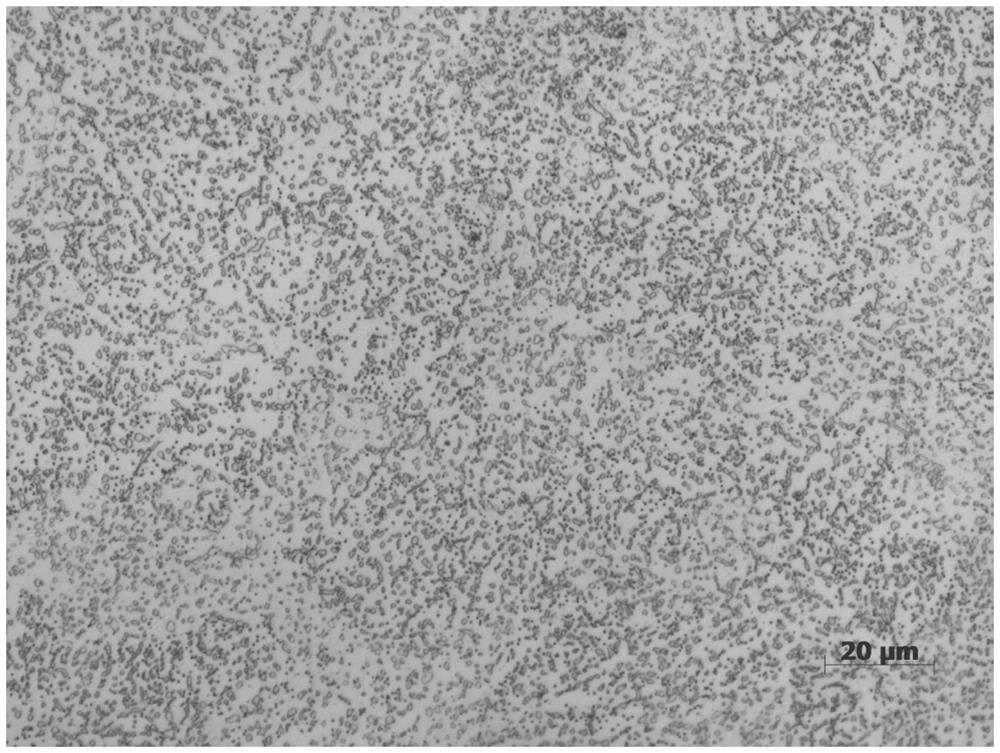

Embodiment 3

[0099] A hot work die steel, according to the mass fraction, basically consists of the elements in Table 3:

[0100] table 3

[0101]

[0102] Its preparation method, the main steps are as follows:

[0103] S1, electric furnace smelting:

[0104] According to the preparation of scrap steel and alloy materials in advance according to Table 3, scrap steel is first smelted in batches according to the smelting weight in the electric furnace, and the molten steel temperature is 1645 ℃ for oxidation and slag removal. After the slag removal, alloy materials, lime and fluorite are added to adjust the chemical composition and Dephosphorization, the tapping temperature is 1630 ℃, aluminum wire is added during the tapping process, and the aluminum wire is added at 1kg / t for deoxidation.

[0105] S2, ladle refining furnace refining:

[0106] After the electric furnace smelting, the molten steel is transferred to the ladle, hoisted to the refining furnace base, and added with slag CaO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com