Cold-work mould steel material and alloy modifying agent

A technology of cold work die steel and modifier, applied in the field of cold work die steel, can solve the problems of inapplicability of cold work die steel materials, complicated forging process, waste of materials and energy, etc., to improve fluidity and solidification performance, The effect of shortening production cycle and refining grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

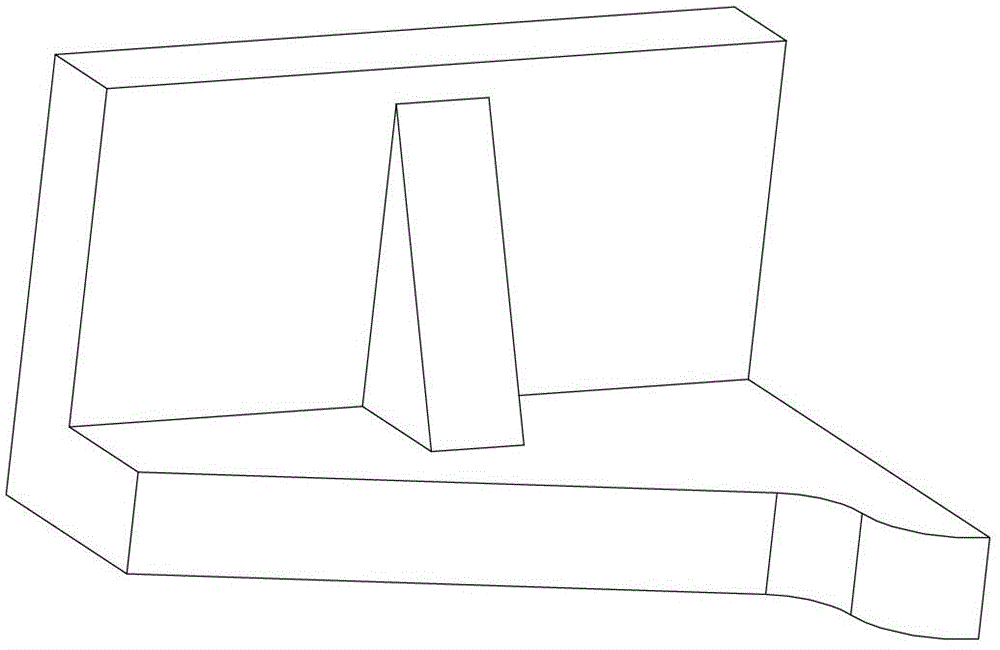

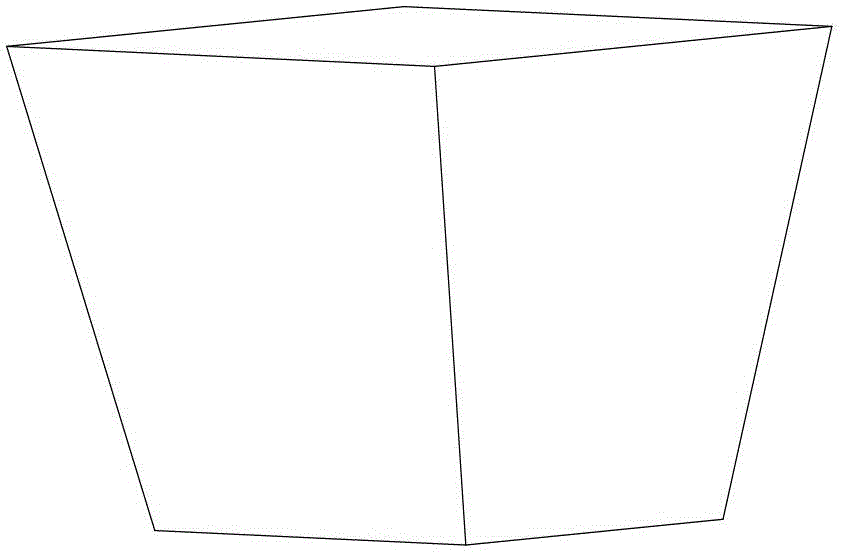

[0016] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

[0017] In addition to Fe, the cold work die steel material of the present invention also contains the following elements in weight percentage: C 1.55-1.75%, Cr 11.50-12.50%, V 0.20-0.30%, Mo 0.45-0.55%, Si ≤0.25%, Mn ≤0.20%, S ≤0.030%, P ≤0.030%, Ni ≤0.15%, Cu ≤0.2%. In a preferred embodiment of the present invention, C 1.72%, Cr 12.03%, V 0.25%, Mo 0.50%, Si ≤0.25%, Mn ≤0.20%, S ≤0.030%, P ≤0.030%, Ni ≤0.15% , Cu ≤0.2%.

[0018] The present invention also provides an alloy modifying agent added to the aforementioned cold work die steel material to improve the performance of the material. The alloy modifier contains the following elements besides Fe, by weight percentage: RE 14.0~20.5%, Mg 3.0~4.5%, Si 25~30%, Mn 3.0~...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com