Horizontal continuous-casting electromagnetic agitating technology

A technology of electromagnetic stirring and horizontal continuous casting, which is applied in the field of iron and steel metallurgy, and can solve problems such as difficult discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

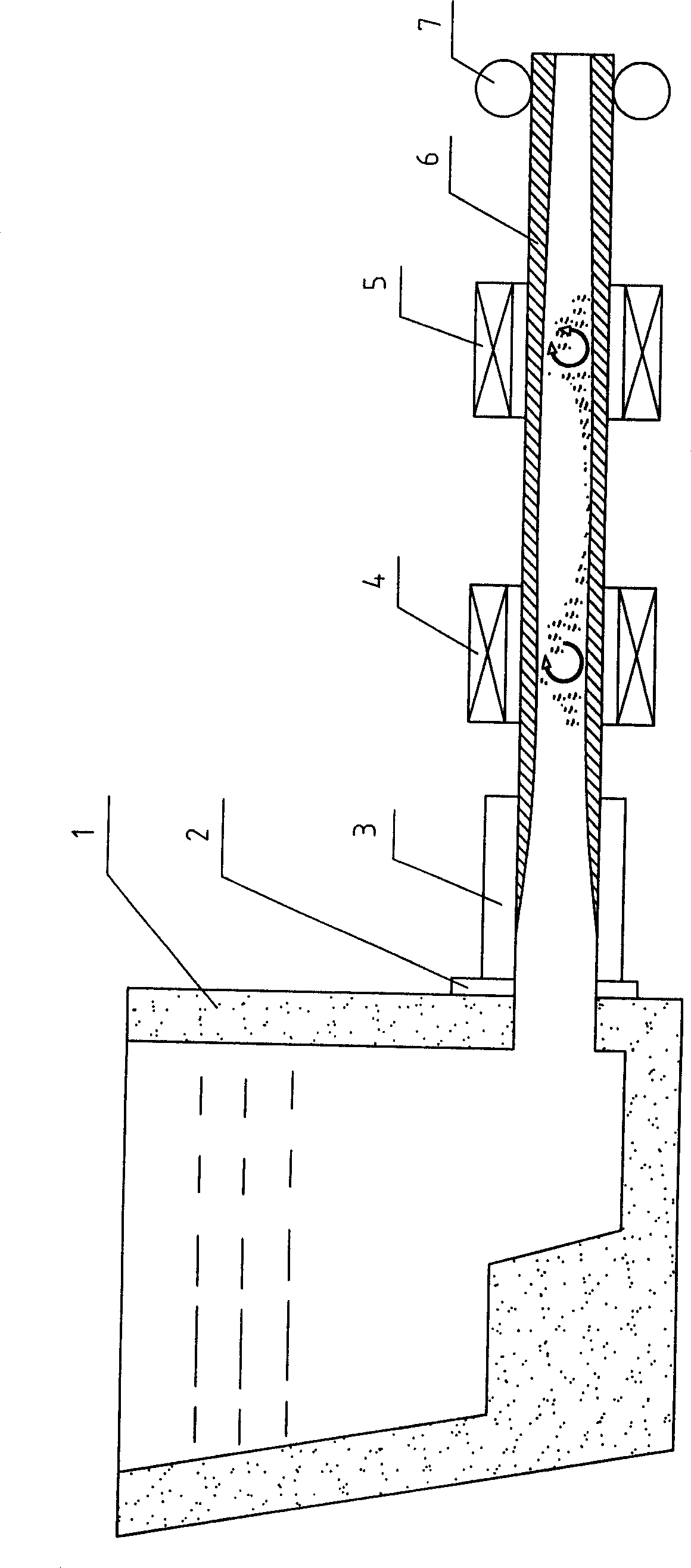

[0024] Embodiment 1: The horizontal continuous casting electromagnetic stirring technology includes a water treatment system for cooling the electromagnetic stirrer, an electric control system for generating low-frequency power, and an industrial control system for setting and adjusting stirring parameters.

[0025] 1. At the beginning of billet casting, the heat of the billet 6 is transferred to the mixer body. Therefore, the cooling water system and control system of electromagnetic stirring should be started in advance.

[0026] 2. The body 4 of the electromagnetic stirrer in the second cooling zone is arranged 2m behind the crystallizer 3 of the horizontal continuous casting machine. Stirring parameters are set differently, and the industrial computer gives a signal to control the magnitude of the current to generate an alternating magnetic field to stir the molten steel in the billet 6 . The stirring current of the electromagnetic stirrer 4 in the second cooling zone is 0...

Embodiment 2

[0029] Embodiment 2: The horizontal continuous casting electromagnetic stirring technology includes a water treatment system for cooling the electromagnetic stirrer, an electric control system for generating low-frequency power, and an industrial control system for setting and adjusting stirring parameters.

[0030] 1. At the beginning of billet casting, the heat of the billet 6 is transferred to the mixer body. Therefore, the cooling water system and control system of electromagnetic stirring should be started in advance.

[0031] 2. The body of the electromagnetic stirrer 5 at the solidification end is arranged 4m in front of the casting roller 7 of the horizontal continuous casting machine. Stirring parameters are set differently, the industrial computer gives a signal to control the magnitude of the current to generate an alternating magnetic field, and stirs the 6 cores of the billet. The stirring current of the electromagnetic stirrer at the solidification end is 0-300A,...

Embodiment 3

[0034] Embodiment 3: The horizontal continuous casting electromagnetic stirring technology includes a water treatment system for cooling the electromagnetic stirrer, an electric control system for generating low-frequency power, and an industrial control system for setting and adjusting stirring parameters.

[0035] 1. At the beginning of billet casting, the heat of the billet 6 is transferred to the mixer body. Therefore, the cooling water system and control system of electromagnetic stirring should be started in advance.

[0036] 2. The body 4 of the electromagnetic stirrer in the second cooling zone is arranged 2m behind the crystallizer 3 of the horizontal continuous casting machine. Stirring parameters are set differently, and the industrial computer gives a signal to control the magnitude of the current to generate an alternating magnetic field to stir the molten steel in the billet 6 . The stirring current of the electromagnetic stirrer 4 in the second cooling zone is 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com