Manufacturing method of ultralow-temperature-impact resistant steel for high-intensity bolt of wind turbine generator set

A technology of high-strength bolts and manufacturing methods, applied in the field of steelmaking, can solve problems such as difficulty in impact work, stability assurance, and confusion, and achieve the effects of improving density and composition segregation, improving low-temperature ductile-brittle transition temperature, and promoting fine dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

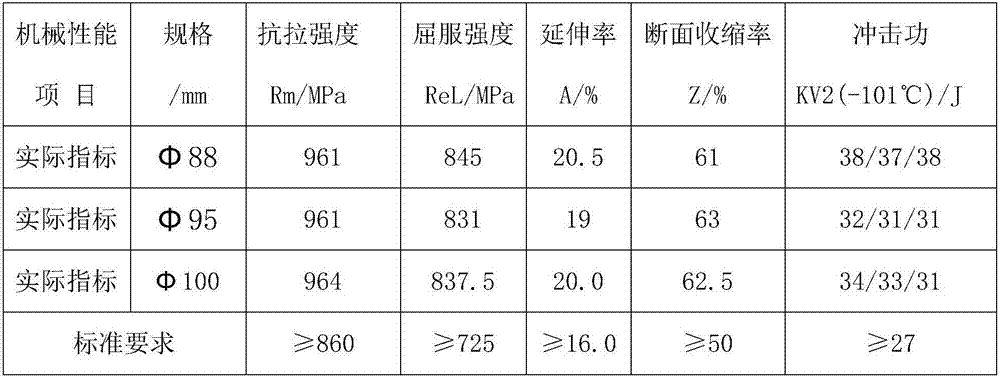

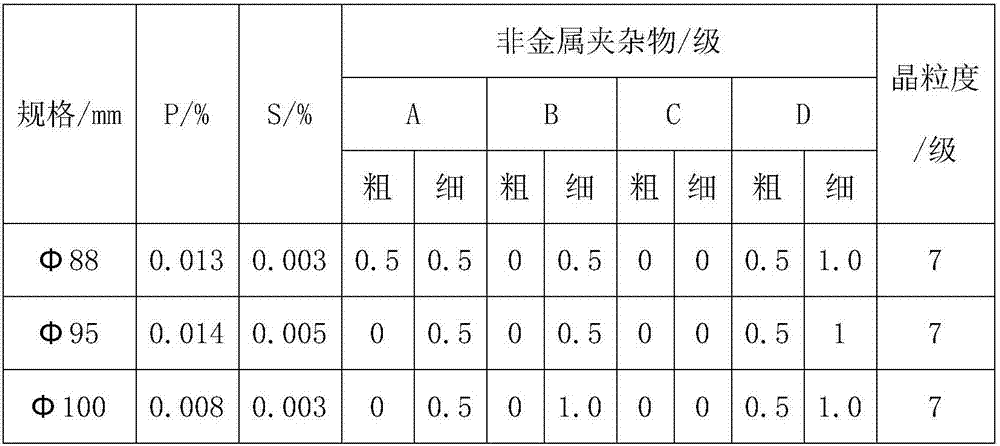

Examples

Embodiment 1

[0032] A method for manufacturing steel for ultra-low temperature impact-resistant wind power high-strength bolts, comprising the following steps:

[0033] Primary smelting of basic converter with top-bottom double blowing: the converter uses 72 tons of high-quality molten iron as the main raw material and 5 tons of pig iron to form the main raw material for steelmaking. Dephosphorization, terminal control (C+Mn) content wt is 0.18%, tapping P content wt is 0.010%; Add SiCaBaAl1.0kg / t steel, steel core aluminum 2.0kg / t steel deoxidation when tapping 15t, ferroalloy ( Ferroalloy materials include ferrosilicon manganese, ferrochrome, nickel plate and ferromolybdenum; among them, 2 / 3 of the nickel plate is added in the primary smelting furnace, 1 / 3 of the amount is added during the tapping process, and the nickel plate is kept at 650°C. hydrogen expansion annealing for 4.5 hours), recarburizer, slag material (slag material including 300kg / furnace lime, 500kg / furnace pre-melting r...

Embodiment 2

[0043] A method for manufacturing steel for ultra-low temperature impact-resistant wind power high-strength bolts, comprising the following steps:

[0044] Primary smelting of basic converter with top-bottom combined blowing: the converter uses 72 tons of high-quality molten iron as the main raw material and 8 tons of pig iron as the main raw material for steelmaking. The hot charging ratio of molten iron reaches 80%. The "double slag" method is adopted in the blowing process Dephosphorization, terminal control (C+Mn) content wt is 0.2%, tapping P content wt is 0.009%; when tapping 20t, add SiCaBaAl1.0kg / t steel, steel core aluminum 2.0kg / t steel deoxidation, ferroalloy ( Ferroalloy materials include ferrosilicon manganese, ferrochromium, nickel plate and ferromolybdenum; among them, 2 / 3 of the nickel plate is added in the primary smelting furnace, and 1 / 3 of the amount is added during the tapping process, and the nickel plate is kept at 750°C. hydrogen expansion annealing for...

Embodiment 3

[0054] A method for manufacturing steel for ultra-low temperature impact-resistant wind power high-strength bolts, comprising the following steps:

[0055] Primary smelting of alkaline converter with top-bottom combined blowing: the converter uses 72t of high-quality molten iron as the main raw material and 7t of pig iron as the main raw material for steelmaking. The hot charging ratio of molten iron reaches 80%. During the blowing process, lime, dolomite, Adding amount of ore, etc., using "double slag" method for dephosphorization, end point control (C+Mn) content wt is 0.18%, tapping P content wt is 0.010%; add SiCaBaAl 1.0kg / t steel and steel core when tapping 18t Aluminum 2.0kg / t steel deoxidation, ferroalloy material (ferroalloy material includes ferrosilicon manganese, ferrochromium, nickel plate and ferromolybdenum; among them, 2 / 3 of the quantity of nickel plate is added in the primary smelting furnace, and 1 / 3 of the quantity is added in the tapping process and the ni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com