High-strength biomedical Mg-Zn-Zr-Fe alloy material with rapid biodegradability, and preparation method thereof

An alloy material and rapid degradation technology, applied in the field of biomedical multi-component magnesium alloys, can solve the problems of loose and shedding of magnesium alloy surface films, reduced corrosion resistance of magnesium alloys, reduced elongation of magnesium alloys, etc. , Improve the effect of component segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

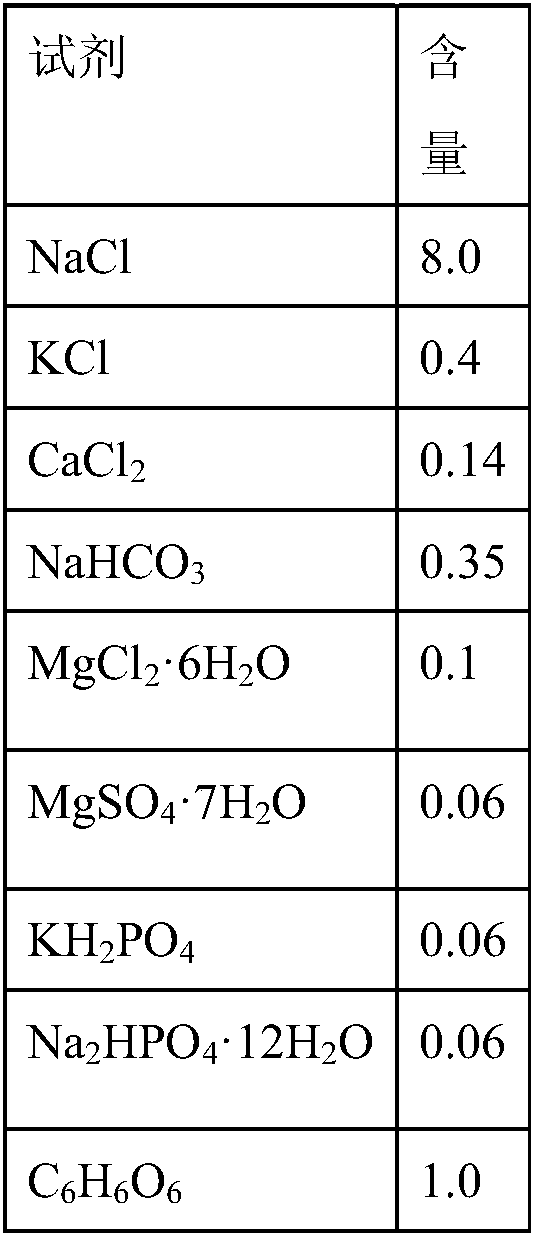

[0034] A kind of high-strength fast degradable biomedical Mg-Zn-Zr-Fe alloy preparation method of the present invention comprises the following steps:

[0035] (1) Raw materials are weighed according to the proportion. The above-mentioned raw materials adopt high-purity magnesium ingots, high-purity zinc ingots, high-purity iron, Mg-30% Zr intermediate alloys, and the above-mentioned raw materials are smelted under the protection of argon by a vacuum induction furnace. Keep warm at ℃ for 40-60 minutes, stir for 5-10 minutes after the above raw materials are melted, then cool down to 730-750 ℃ and refine for 20-30 minutes, after refining, raise the temperature to 750-780 ℃ and let stand for 30-40 minutes, then cast at 710-730 ℃ Ingot;

[0036] (2) Homogenize the above-mentioned cast ingot at 400-420°C, hold for 16-18h, and water-cool at 50-60°C;

[0037] (3) Extrude the homogenized alloy into plates, rods, and wires through an extrusion machine at an extrusion temperature of...

Embodiment 1

[0043] The mass percent of Mg-Zn-Zr-Fe alloy elements is: Zn 5.8%, Zr 0.65%, Fe 0.03%, Al 0.005%, Ni 0.004%, Cu 0.004%, and the rest is Mg.

[0044] The raw materials are: Mg ingot with a purity of 99.995%, Zn ingot with a purity of 99.993%, Fe ingot with a purity of 99.987%, and a Mg-Zr master alloy with a mass percentage of Zr of 29.8% (mass percentage of impurities is 0.004%).

[0045] Weigh the raw materials according to the ratio, melt the above raw materials through a vacuum induction furnace under the protection of argon, keep them at 800°C for 60 minutes, stir for 5 minutes after the above raw materials are melted, then cool down to 730°C and refine for 25 minutes, and then heat up to 760°C after refining. ℃ for 30 minutes, poured into ingots at 710 ℃;

[0046] Homogenize the above-mentioned ingot at 420°C, hold for 16 hours, and water-cool at 60°C;

[0047] Extrude the homogenized alloy into rods through an extruder at an extrusion temperature of 250°C and an extrusi...

Embodiment 2

[0053] The mass percent of Mg-Zn-Zr-Fe alloy elements is: Zn 5.6%, Zr 0.74%, Fe 0.05%, Al 0.004%, Ni 0.003%, Cu 0.004%, and the rest is Mg.

[0054] The raw materials are: a Mg ingot with a purity of 99.995%, a Zn ingot with a purity of 99.993%, an Fe ingot with a purity of 99.987%, and a Mg-Zr master alloy with a Zr mass percentage of 30% (mass percentage of impurities is 0.004%).

[0055] Weigh the raw materials according to the ratio, melt the above raw materials through a vacuum induction furnace under the protection of argon, keep them at 790°C for 50 minutes, stir for 10 minutes after the above raw materials are melted, then cool down to 750°C for 30 minutes, and then heat up to 780°C ℃ for 40 minutes, poured into ingots at 720 ℃;

[0056] Homogenize the above-mentioned ingot at 410°C, hold for 18 hours, and water-cool at 55°C;

[0057] Extrude the homogenized alloy into a rod through an extruder at an extrusion temperature of 280°C and an extrusion speed of 0.3mm / s, wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com