Extrusion device and method for connecting magnesium alloy with aluminum alloy

An extrusion device, aluminum alloy technology, applied in the connection of aluminum alloys and magnesium alloys, can solve the problems of too large difference in the diffusion speed of elements, reduced bonding performance at the interface, and difficulty in stable temperature control, so as to improve the connection quality and improve the The effect of its own strength and fast forming speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

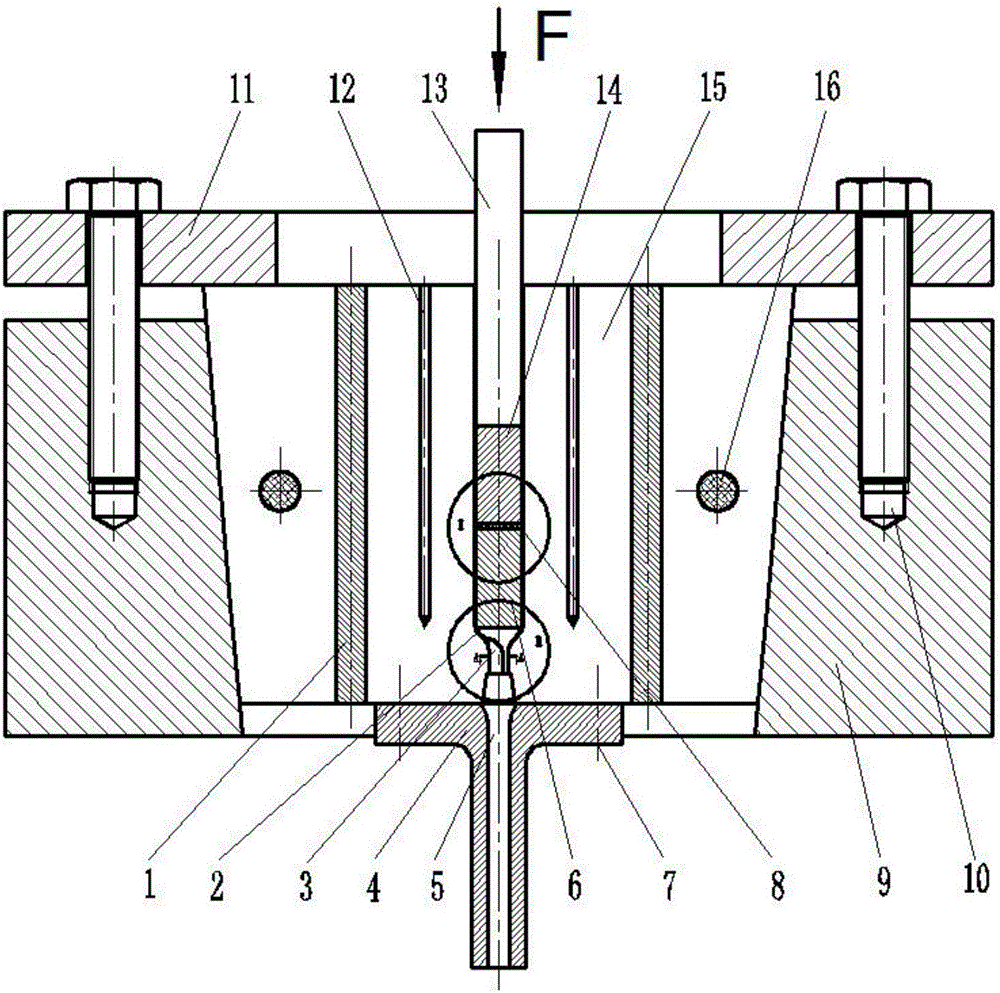

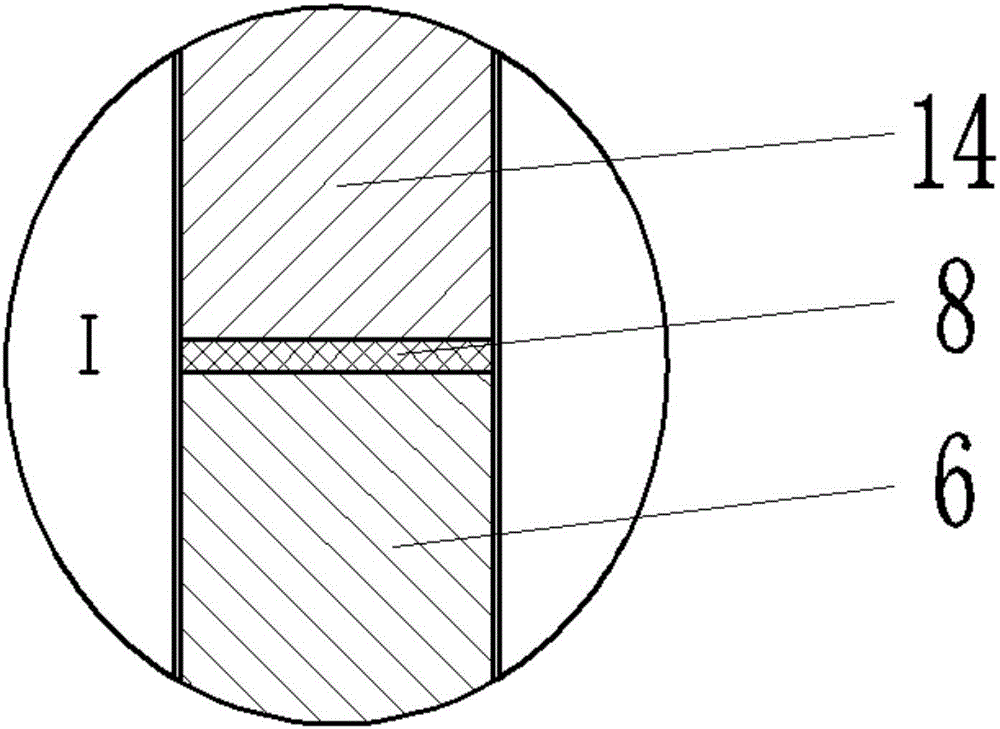

[0057] Such as figure 2 As shown, an extrusion device for connecting magnesium alloy and aluminum alloy includes a mould, the mold includes a die 15 and a punch 13, the punch 13 is rod-shaped, the die 15 is provided with an extrusion chamber 2, and the die 15 An electric heating element such as an electric heating element 1 is arranged outside the extrusion chamber 2, the length of the punch 13 is longer than the depth of the extrusion chamber 2, and the extrusion chamber 2 communicates with the molding chamber 3 of the set shape, such as image 3 As shown, the volume of the molding chamber 3 is smaller than that of the extrusion chamber 2, the molding chamber 3 communicates with the outside world or communicates with the outside world through the guide sleeve 4, and the punch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com