2007 aluminum alloy rod processing process

A processing technology and technology of aluminum alloy, applied in the field of aluminum alloy processing, can solve the problems of reduced mechanical properties of rods, high crack tendency of extruded rods, rapid decline, etc., to improve comprehensive performance, avoid bright grains, reduce The effect of component segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

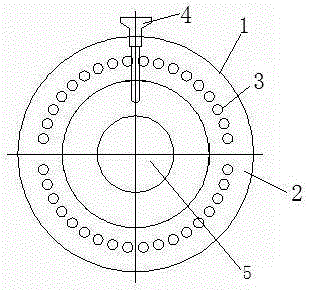

Image

Examples

Embodiment 1

[0018] (1) Ingredients: The mass percentage of each element is: Si: 0.80%, Fe: 0.80%, Cu: 4.6%, Mn: 0.5%, Mg: 1.8%, Cr: 0.1%, Zn: 0.8%, Ti: 0.2% , Pb: 1.5%, Ni: 0.2%, Bi: 0.2%, Sn: 0.2%, other unavoidable impurities: 0.15%, Al balance; (2) Add each element into the melting furnace in turn, and the melting temperature is 715°C ;When molten aluminum appears in the furnace, carry out electromagnetic stirring; pass argon gas into the smelting furnace for refining and removing impurities, and the flow rate of argon gas is controlled at 55 scfh; carry out slag removal to obtain qualified aluminum liquid; inject the aluminum liquid into the holding furnace Carry out heat preservation, and the heat preservation time is 20min at a temperature of 740°C; add aluminum titanium boron refiner to refine; (3) Filtration: use a foam ceramic filter plate to filter the melt, and the filtration temperature is controlled at 725°C; (4 ) Casting: pour the melt obtained in step (3) into the mold at a...

Embodiment 2

[0020] (1) Ingredients: The mass percentage of each element is: Si: 0.50%, Fe: 0.60%, Cu: 3.3%, Mn: 1.0%, Mg: 0.4%, Cr: 0.02%, Zn: 0.7%, Ti: 0.1% , Pb: 0.8%, Ni: 0.1%, Bi: 0.15%, Sn: 0.17%, other unavoidable impurities: 0.1%, Al balance; (2) Add each element into the melting furnace in turn, and the melting temperature is 750°C ;When molten aluminum appears in the furnace, carry out electromagnetic stirring; feed argon gas into the smelting furnace for refining and impurity removal, and the flow rate of argon gas is controlled at 35scfh; slag is removed to obtain qualified aluminum liquid; the aluminum liquid is injected into the holding furnace for Heat preservation, the heat preservation time is 25min at a temperature of 705°C; add aluminum titanium boron refiner for refinement; (3) Filtration: filter with a foam ceramic filter plate to obtain a melt, and the filtration temperature is controlled at 695°C; (4 ) Casting: pour the melt obtained in step (3) into the mold at a ca...

Embodiment 3

[0022](1) Ingredients: The mass percentage of each element is: Si: 0.20%, Fe: 0.10%, Cu: 4%, Mn: 0.7%, Mg: 1.2%, Cr: 0.05%, Zn: 0.2%, Ti: 0.15% , Pb: 1.1%, Ni: 0.05%, Bi: 0.09%, Sn: 0.1%, other unavoidable impurities: 0.05%, Al balance; (2) Add each element into the melting furnace in turn, and the melting temperature is 725°C ;When molten aluminum appears in the furnace, carry out electromagnetic stirring to remove slag; pass argon gas into the smelting furnace for refining and removing impurities, and the flow rate of argon gas is controlled at 45scfh; carry out slag removal to obtain qualified aluminum liquid; inject the aluminum liquid into the insulation Carry out heat preservation in the furnace, and the heat preservation time is 30min at a temperature of 730°C; add aluminum titanium boron refiner for refinement; (3) Filtration: filter with a foam ceramic filter plate to obtain a melt, and the filtration temperature is controlled at 705°C ; (4) Casting: inject the melt o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com