Pure aluminum cathode foil for capacitors and manufacturing method thereof

A manufacturing method and cathode foil technology, applied in capacitors, electrolytic capacitors, circuits, etc., can solve problems such as uneven corrosion of cathode foils, achieve uniform corrosion morphology, reduce production and equipment costs, and low leakage current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A pure aluminum cathode foil for capacitors, the composition and mass percentage of which are: Si 0.04%, Fe 0.24%, Cu 0.19%, Ti 0.038%, and the balance is Al.

[0034] A manufacturing method comprising the steps of:

[0035] The first step, casting and rolling and slag removal process:

[0036] (1) Send the electrolytic aluminum liquid to the smelting furnace, add solid material (cold-rolled scrap), and adjust the mass percentage of each element in the melt to be: Si 0.04%, Fe 0.24%, Cu 0.19%, Ti 0.038%, The balance is Al, and the melt temperature is controlled within the range of 760°C;

[0037] (2) Use nitrogen gas to spray powder spraying refining agent HZ-PF with 0.3% of the melt mass into the melt, refine for 22 minutes, and then stand for 20 minutes to remove the scum on the surface of the molten aluminum, transfer it to a standing furnace, and control The temperature is at 745°C;

[0038] (3) Send the molten aluminum in the static furnace into the launder, add...

Embodiment 2

[0045] The difference from Example 1 is that in the second step (2), the recrystallization annealing process is adjusted to: 250°C / 1.5h, 250°C / 4h, 250°C / 8h, 400°C / 1.5h, 400°C / 4h, 400°C / 8h.

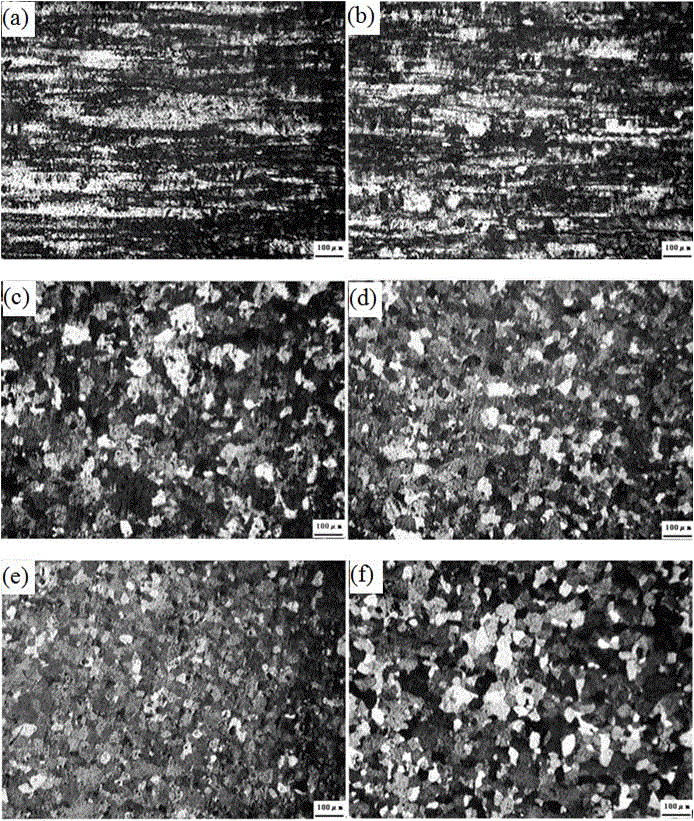

[0046] image 3It is the recrystallized grains of pure aluminum cathode foil blanks with different annealing processes. It can be seen that when the annealing temperature is 250°C, the recrystallized grains grow significantly with the prolongation of the annealing time; when the annealing temperature is 400°C, the recrystallized grains have no obvious growth trend.

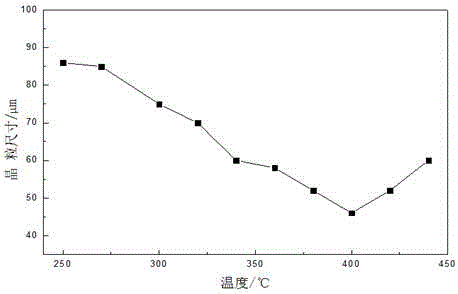

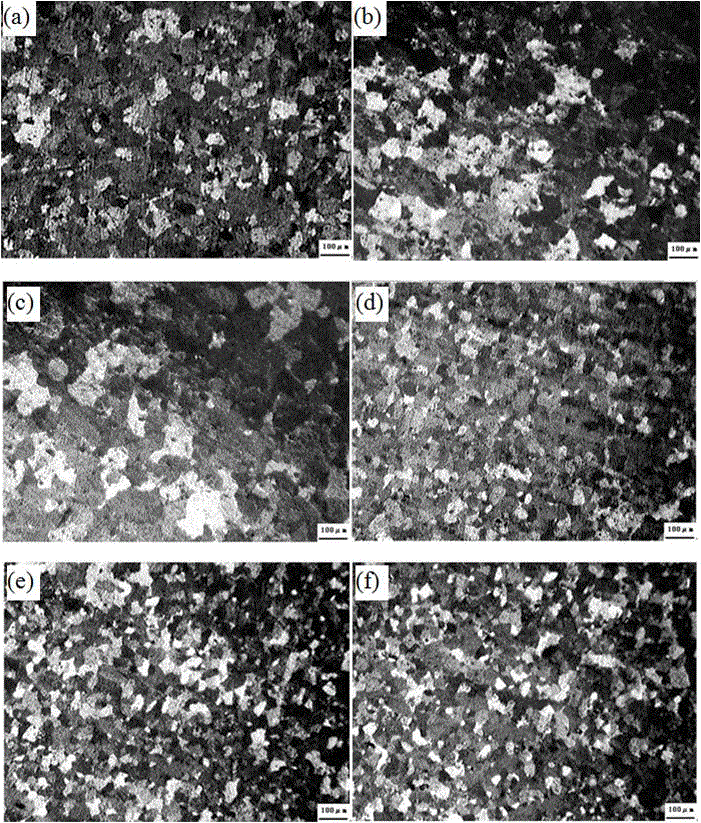

[0047] Figure 4 The microstructures of pure aluminum cathode foil blanks with different annealing processes. Table 1 shows the statistics of the second phase particles of pure aluminum cathode foil blanks corresponding to each annealing process. It can be seen that the precipitation of the second phase of the blanks after annealing at 250 ° C and 400 ° C is significantly different. When holding for 2 hours, after recryst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com