A kind of preparation method of wc co cemented carbide for mining

A cemented carbide, mining technology, applied in the field of powder metallurgy, can solve the problems of reducing the service life of alloys, broken teeth, broken teeth, etc., and achieve the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

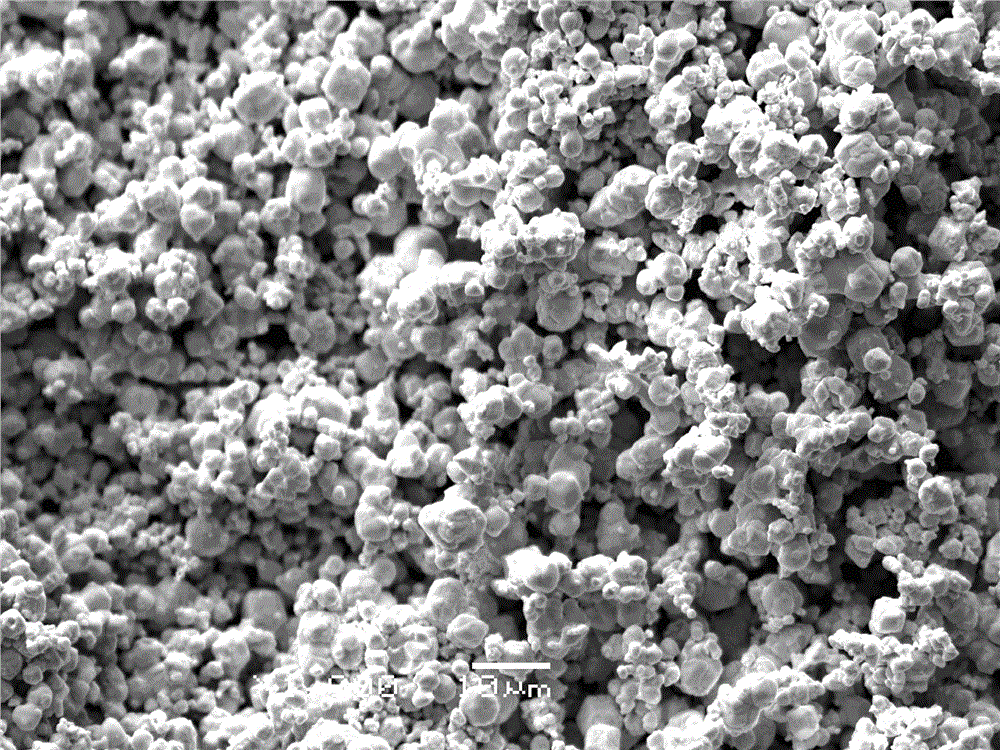

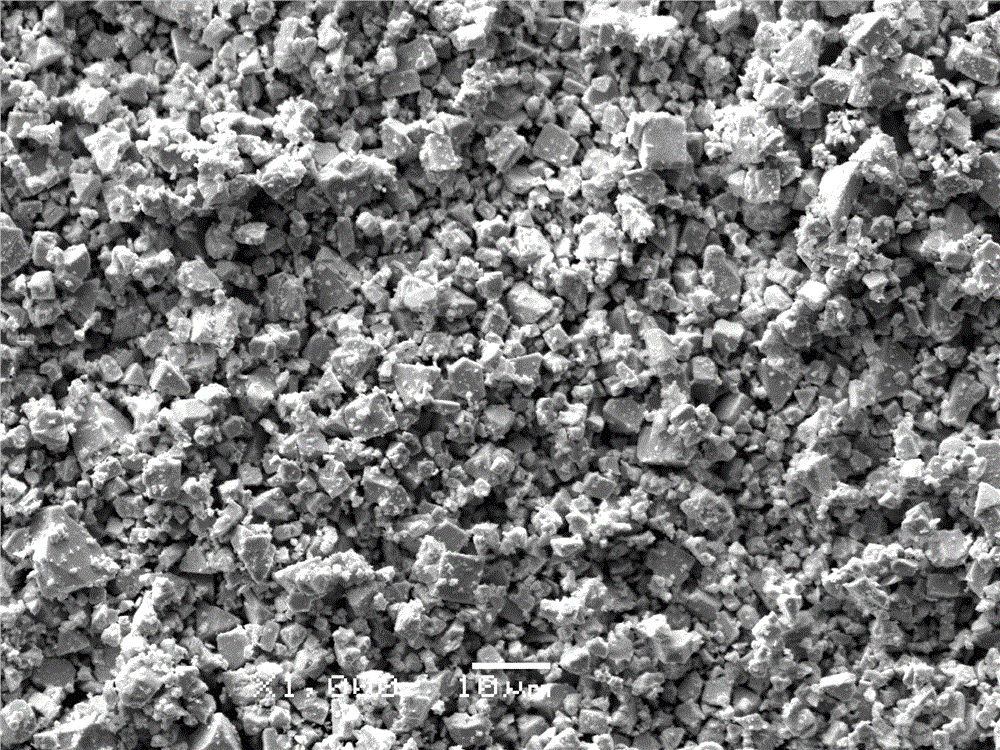

Image

Examples

Embodiment 1

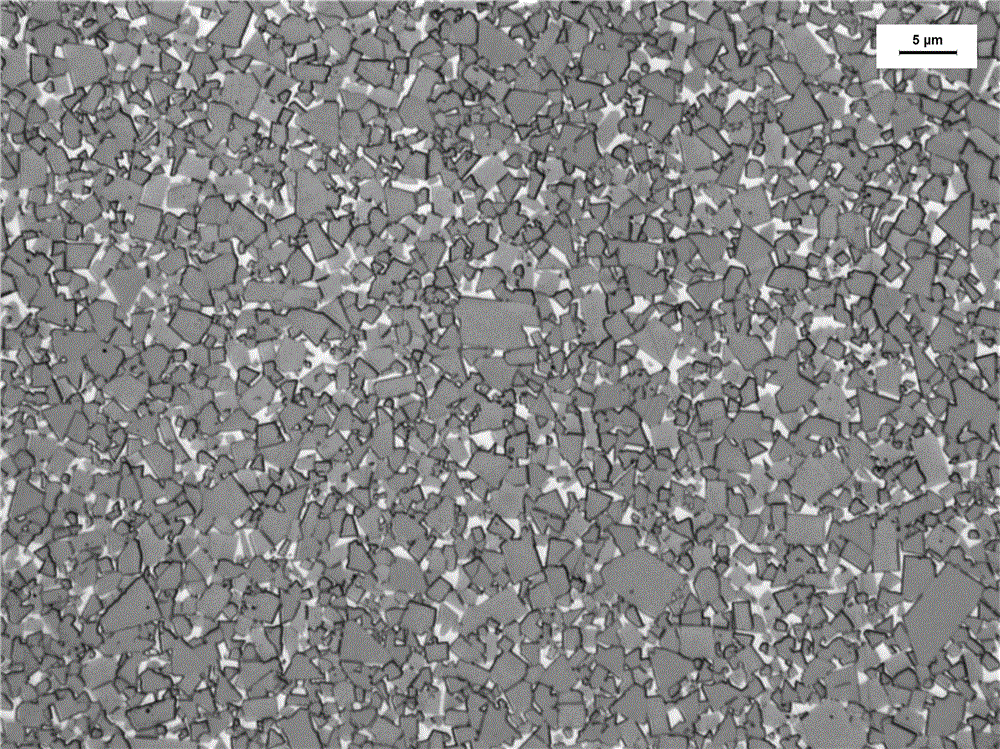

[0017] Example 1: Production of rock drilling inserts with a cobalt content of 11% (mass percentage, the same below), and determining the target coercive force Hc of the raw material according to the grade 目标 is 6.9kA / m, the raw material Hcp of the recycled WC is selected 再生 It is 7.2kA / m, Ti原生 It is 6.3kA / m. After calculation, the recycled WC accounts for 66.7% of the WC raw material. The above-mentioned regenerated WC, primary WC and cobalt powder were mixed evenly, wet milled for 18 hours, dried and granulated, pressed and sintered under pressure at 1450°C (pressure 5~70bar). The properties and grain size of the obtained WC-Co cemented carbide for mining are shown in Table 1.

Embodiment 2

[0018] Embodiment 2: Production of rock drilling inserts with a cobalt content of 10%, determining the target coercive force Hc of the raw material according to the grade 目标 is 6.2kA / m, the raw material Hcp of the regenerated WC selected 再生 It is 7.0kA / m, Ti原生 It is 5.0kA / m. After calculation, the recycled WC accounts for 60% of the WC raw material. Mix the above regenerated WC, primary WC and cobalt powder evenly, wet mill for 20 hours, dry granulate, press and sinter at 1450°C (pressure 5~70bar), the obtained WC-Co cemented carbide for mining The properties and grain size are shown in Table 1.

Embodiment 3

[0019] Example 3: To produce rock drilling buttons with a cobalt content of 8%, and determine the target coercive force Hc of the raw material according to the grade 目标 is 7.2kA / m, the raw material Hcp of the regenerated WC is selected 再生 It is 7.0kA / m, Ti原生 It is 7.4kA / m. After calculation, the recycled material WC accounts for 50% of the WC raw material. Mix the above-mentioned regenerated WC, primary WC and cobalt powder evenly, wet mill for 23 hours, dry granulate, press and sinter at 1450°C (pressure 5~70bar), the obtained WC-Co cemented carbide for mining The properties and grain size are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com