High-room-temperature-elongation wrought magnesium alloy and preparation method thereof

A technology of deforming magnesium alloy and elongation rate, which is applied in the field of nonferrous metallurgy, can solve the problems of high cost, complicated process, and restrictions on alloy application, and achieve the effects of high room temperature shaping, large application prospects, and high room temperature ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

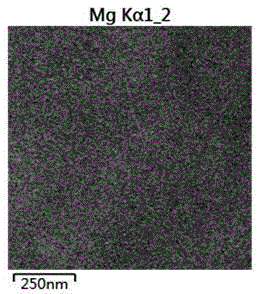

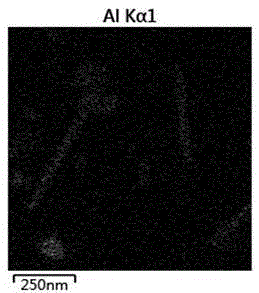

Image

Examples

Embodiment 1

[0047] A wrought magnesium alloy with high elongation at room temperature, the mass fraction of each element in the wrought magnesium alloy is: Al: 1.8%, Mn: 0.15%, Ca: 0.3%, and the balance is magnesium.

[0048] The above-mentioned wrought magnesium alloy is made by sequentially adding Al, Mn, and Ca elements in the magnesium ingot, including the following steps:

[0049] 1). Dry all furnace materials and utensils;

[0050] 2). Put the magnesium ingot into the graphite crucible, put the graphite crucible into the box-type resistance furnace, sprinkle the No. 5 smelting covering agent for magnesium alloy smelting on the surface of the magnesium ingot, and blow argon gas (purity 99.9% ), to prevent massive oxidation and burning of magnesium alloys during smelting;

[0051] 3). After the magnesium ingot is melted and the melt temperature reaches 740°C, add the required mass of industrially pure Al (purity 99.9%) to the magnesium ingot melt, and stir evenly so that the mass fra...

Embodiment 2

[0055] A wrought magnesium alloy with high elongation at room temperature, the mass fraction of each element in the wrought magnesium alloy is: Al: 2%, Mn: 0.2%, Ca: 0.4%, and the balance is magnesium.

[0056] The wrought magnesium alloy is made by only sequentially adding Al, Mn, and Ca elements in the magnesium ingot, comprising the following steps:

[0057] 1). Dry all furnace materials and utensils;

[0058] 2). Put the magnesium ingot into the graphite crucible, put the graphite crucible into the box-type resistance furnace, sprinkle the No. 5 smelting covering agent for magnesium alloy smelting on the surface of the magnesium ingot, and blow argon gas (purity 99.9% ), to prevent a large amount of oxidation and combustion of magnesium alloys during smelting;

[0059] 3). After the magnesium ingot is melted and the melt temperature reaches 740°C, add the required mass of industrially pure Al (purity 99.9%) to the magnesium ingot melt, and stir evenly so that the mass fra...

Embodiment 3

[0063] A wrought magnesium alloy with high elongation at room temperature, the mass fraction of each element in the wrought magnesium alloy is: Al: 1.9%, Mn: 0.18%, Ca: 0.36%, and the balance is magnesium.

[0064] The above-mentioned wrought magnesium alloy is made by successively adding Al, Mn, and Ca elements in the magnesium ingot, comprising the following steps:

[0065] 1). Dry all furnace materials and utensils;

[0066] 2). Put the magnesium ingot into the graphite crucible, put the graphite crucible into the box-type resistance furnace, sprinkle the No. 5 smelting covering agent for magnesium alloy smelting on the surface of the magnesium ingot, and blow argon gas (purity 99.9% ), to prevent massive oxidation and burning of magnesium alloys during smelting;

[0067] 3). After the magnesium ingot is melted and the melt temperature reaches 740°C, add the required mass of industrially pure Al (purity 99.9%) to the magnesium ingot melt, and stir evenly so that the mass f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com