A thermochromic intelligent dimming film with low phase transition temperature and preparation method thereof

A technology of phase change temperature and intelligent light adjustment, which is applied in chemical instruments and methods, optics, nonlinear optics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

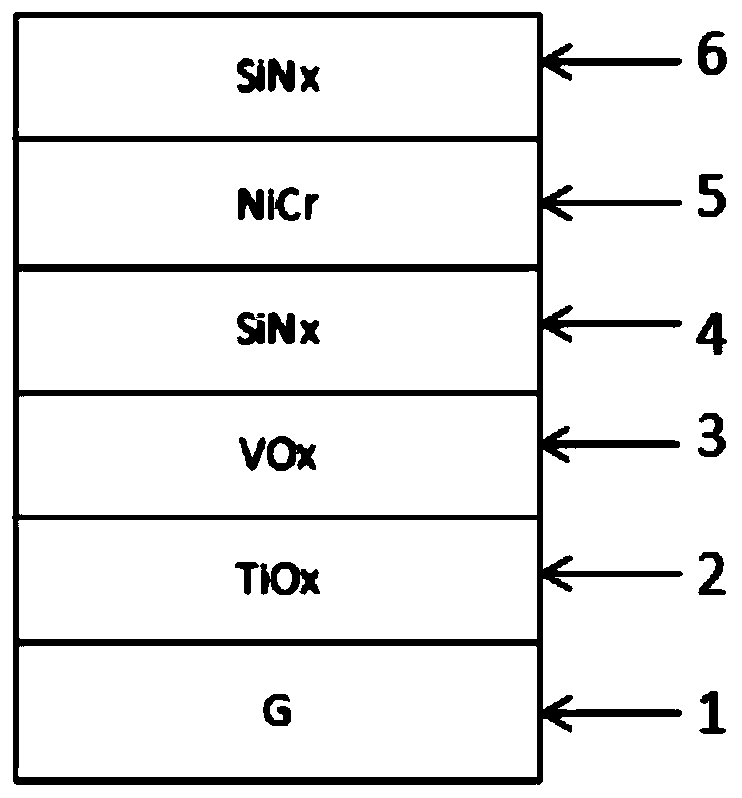

[0045] Such as figure 1 As shown, a thermochromic smart dimming film with a low phase transition temperature includes a substrate 1 , a first dielectric layer 2 , a vanadium oxide layer 3 , a crystallization-promoting layer 4 , an anti-oxidation layer 5 and a second dielectric layer 6 . The substrate 1 is a glass material, the first dielectric layer 2 is a TiOx material, the vanadium oxide layer 3 is a vanadium oxide material with phase change properties, the crystallization-promoting layer 4 is a SiNx material, the anti-oxidation layer 5 is a NiCr material, and the second The dielectric layer 6 is made of SiNx material.

[0046] The preparation method of the thermochromic intelligent dimming film of described low phase transition temperature is as follows: adopt magnetron sputtering coating mode, adopt TiOx successively (in Ar, O 2 atmosphere), V (in Ar, O 2 atmosphere), Si (in Ar, N 2 atmosphere), NiCr (under Ar atmosphere), Si (under Ar, N 2 atmosphere) as a target, seq...

Embodiment 2

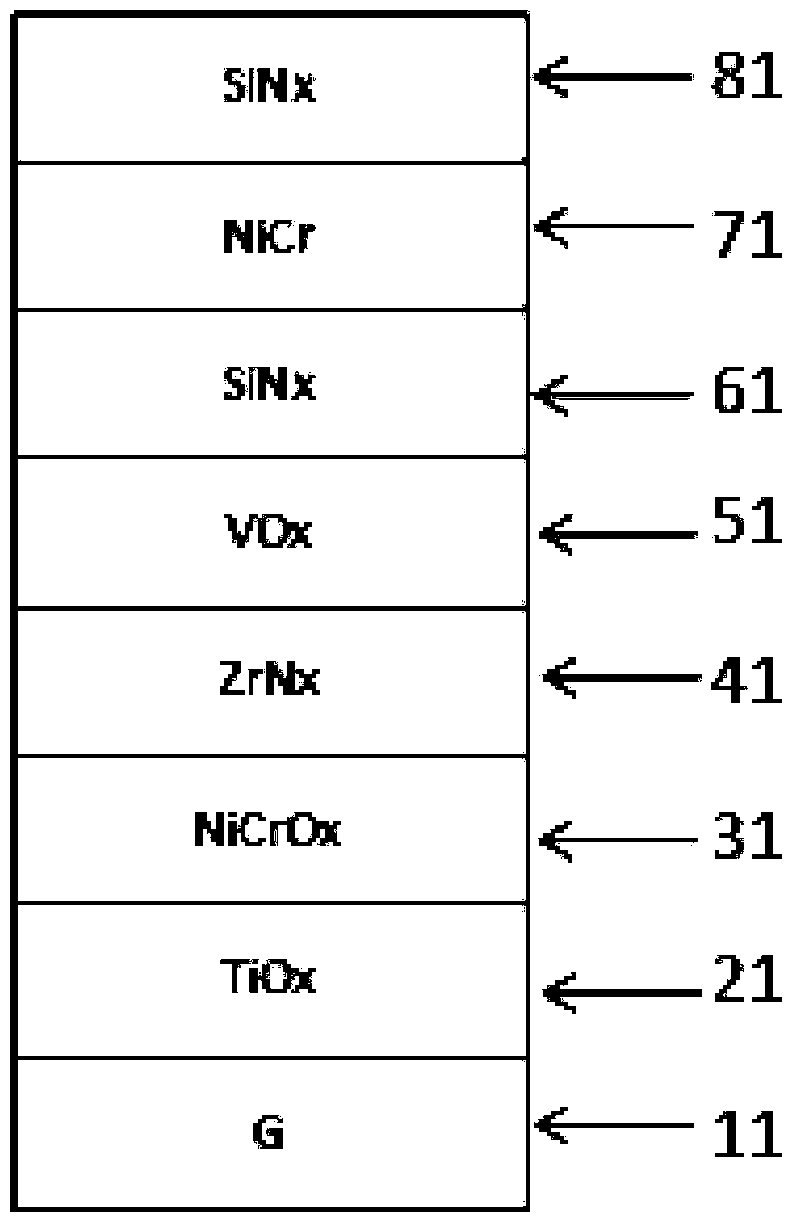

[0049] Such as figure 2As shown, a thermochromatic smart dimming film with a low phase transition temperature includes a substrate 11, a first dielectric layer 21, a first anti-oxidation layer 31, a first crystallization-promoting layer 41, a vanadium oxide layer 51, a second The crystallization-promoting layer 61 , the second anti-oxidation layer 71 and the second dielectric layer 81 . The substrate 11 is made of glass material, the first dielectric layer 21 is made of TiOx material, the first anti-oxidation layer 31 is made of NiCrOx material, the first crystallization-promoting layer 41 is made of ZrNx material, and the vanadium oxide layer 51 is vanadium oxide with phase change properties material, the second crystallization-promoting layer 61 is made of SiNx material, the second anti-oxidation layer 71 is made of NiCr material, and the second dielectric layer 81 is made of SiNx material.

[0050] The preparation method of the thermochromic intelligent dimming film of de...

Embodiment 3

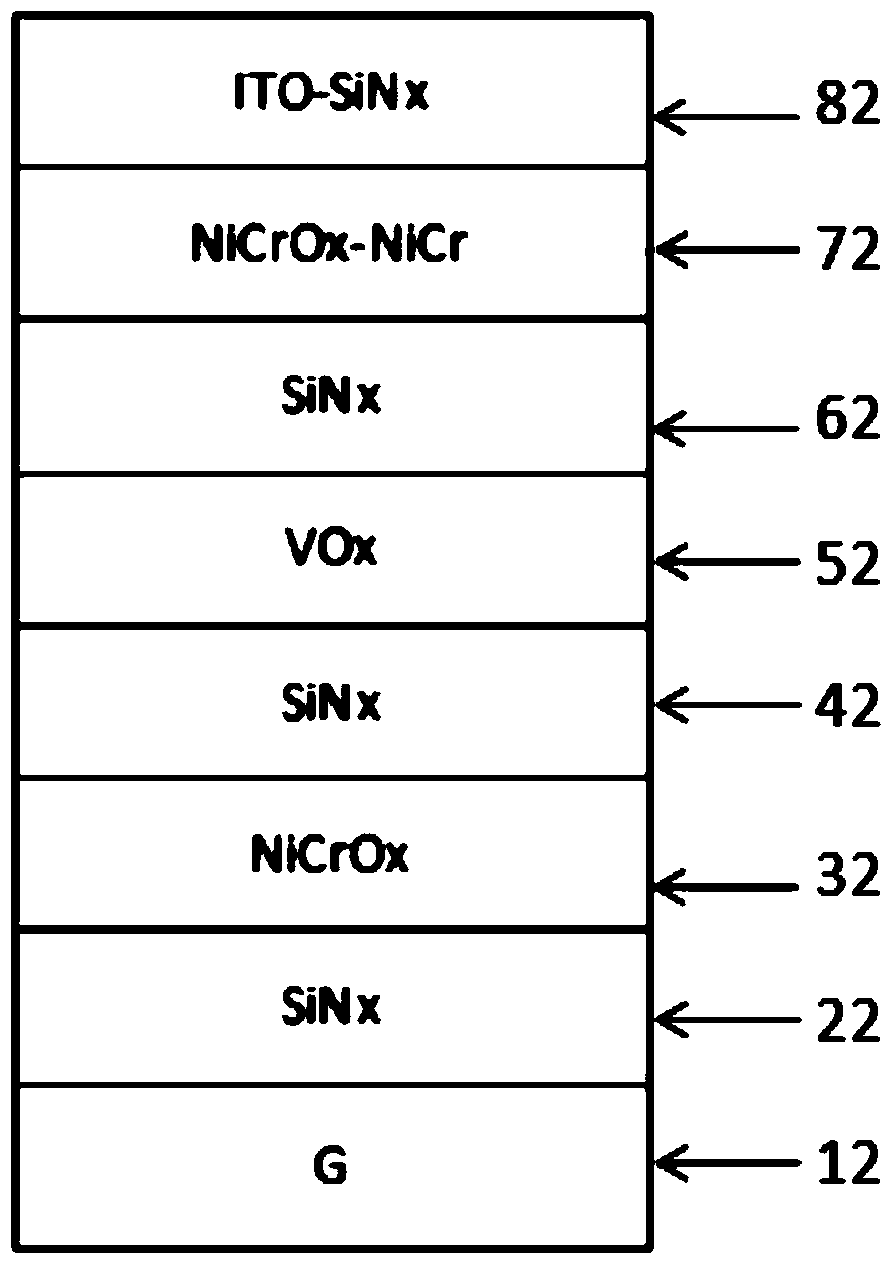

[0053] Such as image 3 As shown, a thermochromatic smart dimming film with a low phase transition temperature includes a substrate 12, a first dielectric layer 22, a first anti-oxidation layer 32, a first crystallization-promoting layer 42, a vanadium oxide layer 52, a second The crystallization-promoting layer 62 , the second anti-oxidation layer 72 and the second dielectric layer 82 . The substrate 12 is made of glass material, the first dielectric layer 22 is made of SiNx material, the first anti-oxidation layer 32 is made of NiCrOx material, the first crystallization-promoting layer 42 is made of SiNx material, and the vanadium oxide layer 52 is made of vanadium oxide with phase change properties. materials, the second crystallization-promoting layer 62 is SiNx material, the second anti-oxidation layer 72 is a NiCrOx-NiCr composite layer, and the second dielectric layer 82 is an ITO-SiNx composite layer.

[0054] The preparation method of the thermochromic intelligent di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com