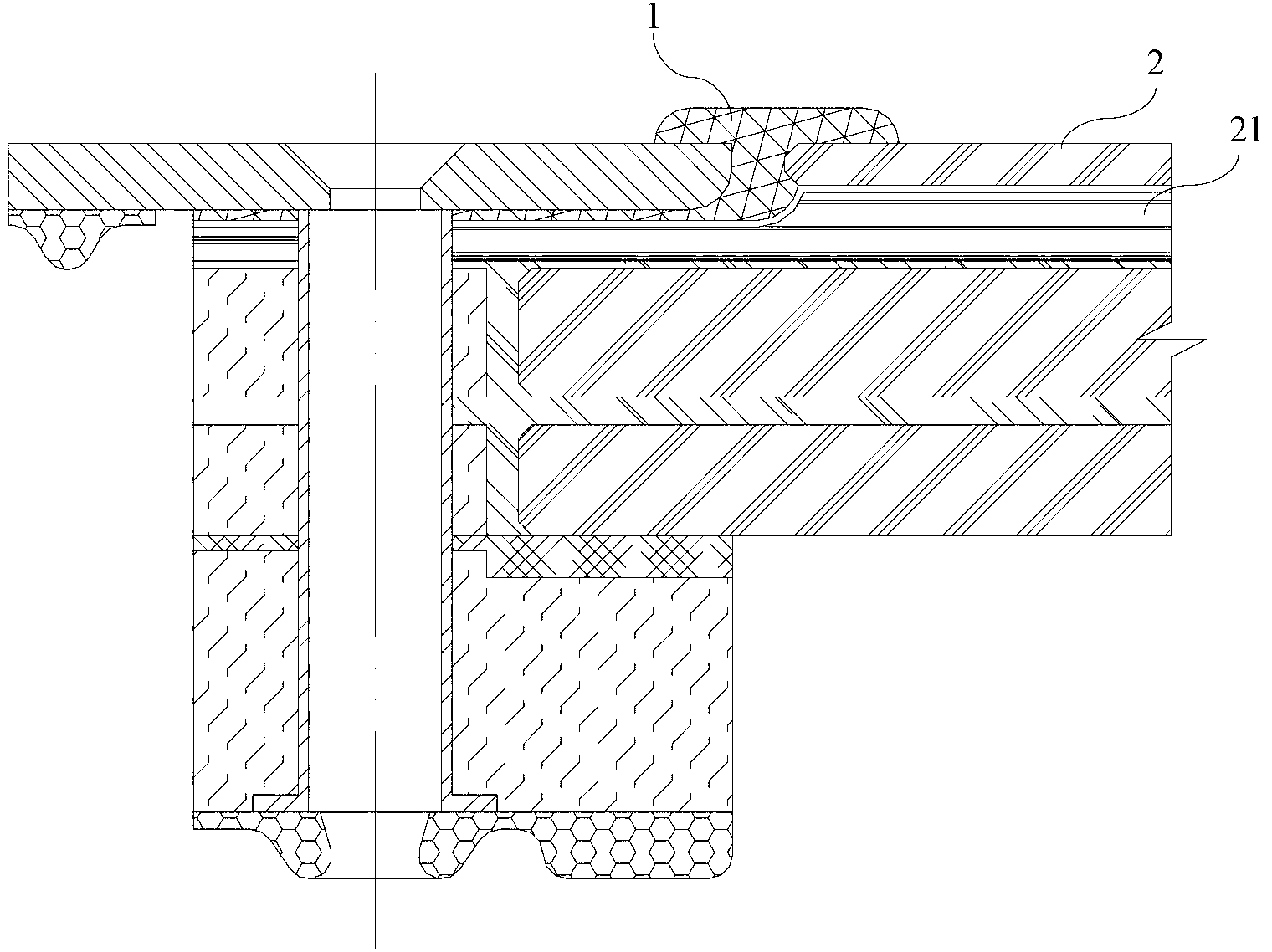

[0005] 1. If Figure 1-Figure 2 As shown, when installing the transparent part 2, since the

sealant 1 is made of elastic material and the tightening force of each bolt is different, when the bolts are tightened, the aluminum

alloy frame will be pressed to deform the

sealant 1, and then the edge of the

sealant 1 will be torn A gap is formed between the sealant 1 and the transparent part 2, making it easier for

moisture to penetrate into the transparent part 2, corroding the transparent organic material interlayer (hereinafter referred to as the organic interlayer) 21 and the internal structure of the transparent part 2, accelerating its aging and failure, and This will lead to the degradation and

cracking of the internal interlayer, and even the separation of the glass and the interlayer, posing a major safety

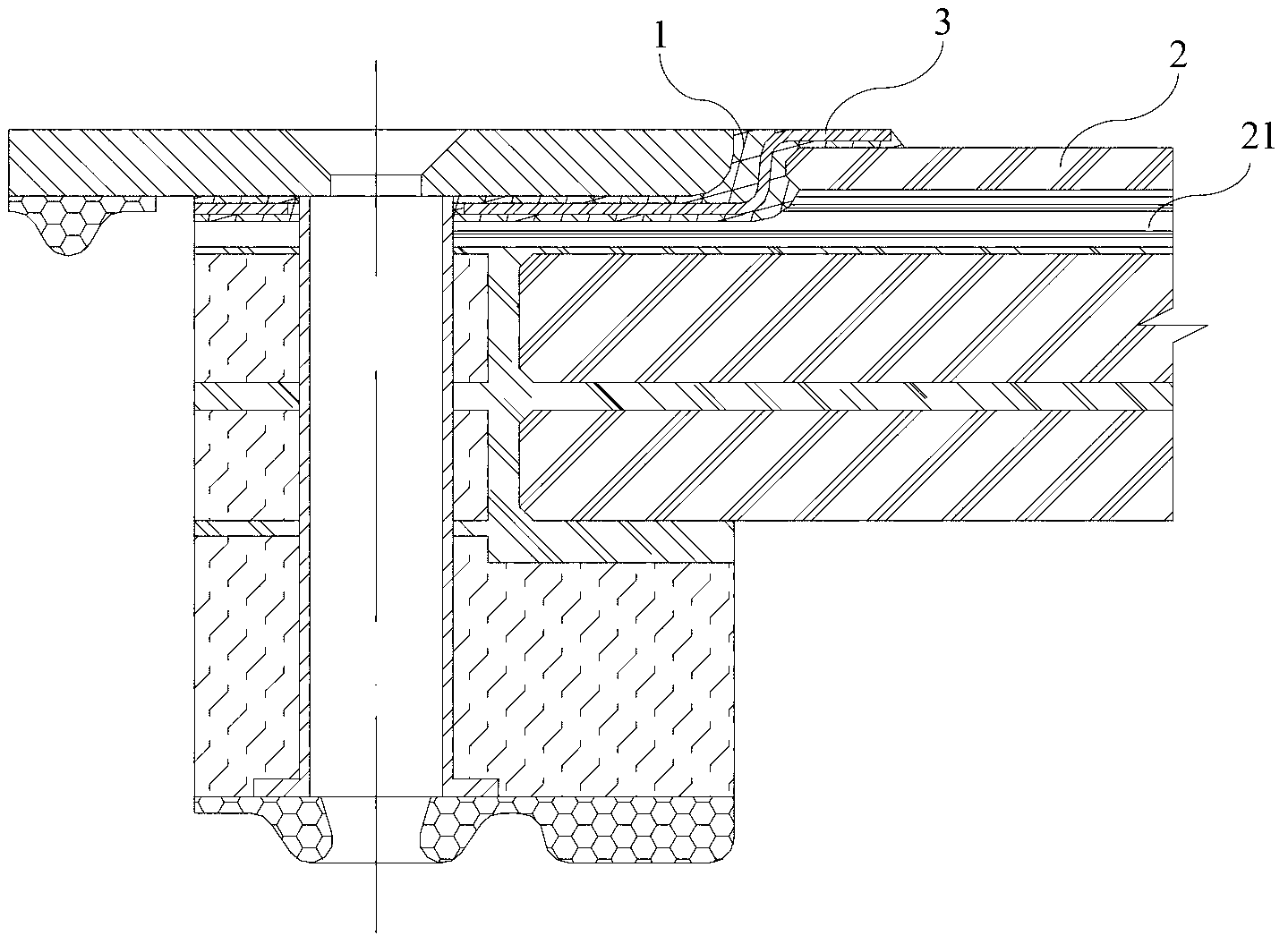

hazard[0006] 2. If Figure 1-Figure 3 , Figure 5 As shown, opening a hole on the organic interlayer 21 of the transparent part 2 has already destroyed the initial

internal stress balance of the interlayer, and the vicinity of the hole becomes a weak link in strength, coupled with possible superimposed

processing defects and

assembly stress, the interlayer is very easy. Cracks are generated. Once encountering

foreign object impact or

aerodynamic load and

body vibration during use, it may cause the interlayer crack to expand or even completely rupture, causing the cabin to lose its security and cause danger.

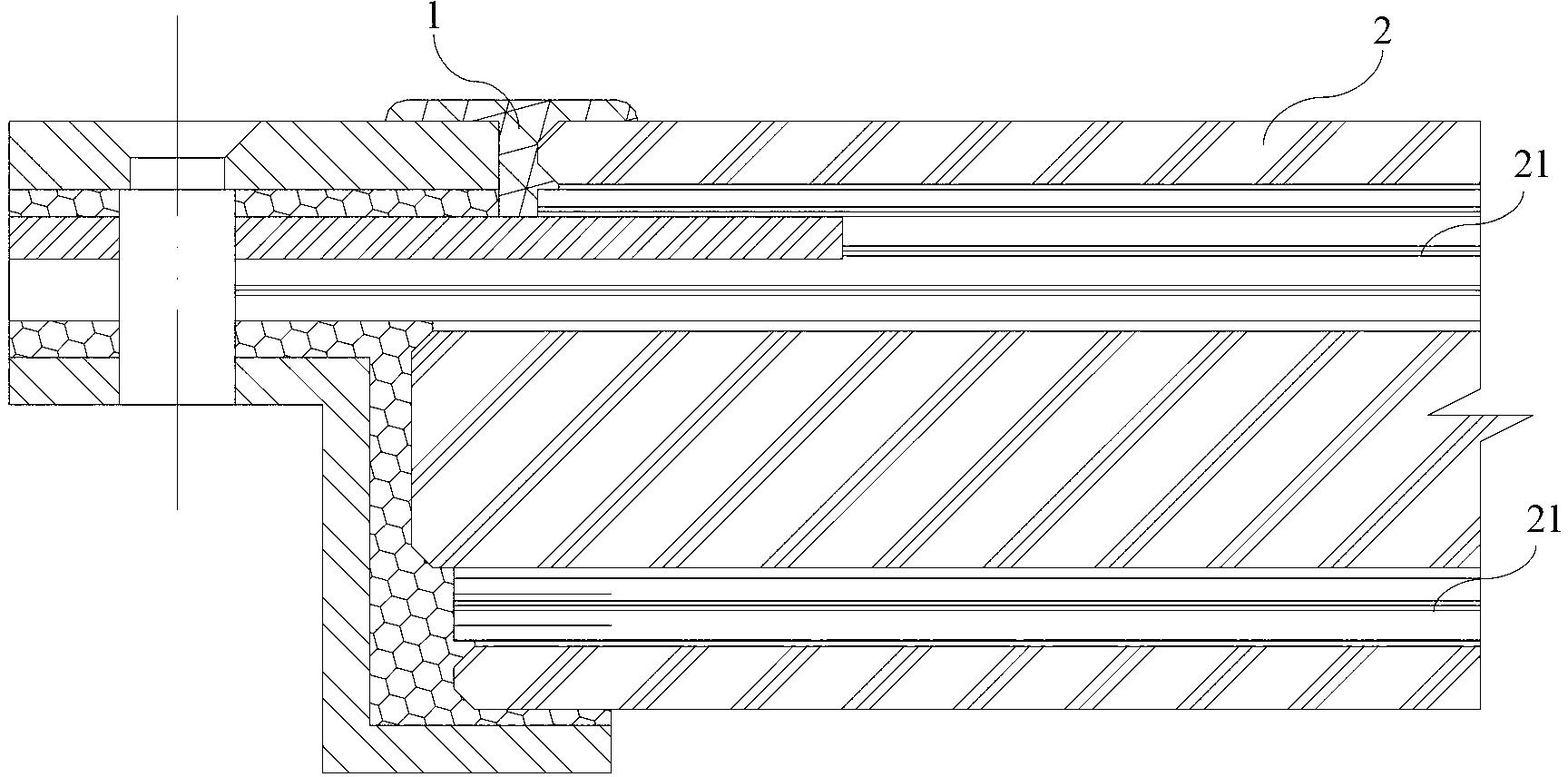

[0007] 3. If Figure 4 As shown, although the installation structure avoids the

internal stress balance damage and

stress concentration problems caused by the interlayer

punching of the transparent part 2, the transparent part 2 cannot be firmly installed on the

fuselage frame. When the transparent part 2 is subjected to a

pressure difference When factors such as

temperature difference change or external

impact are affected, the structural

adhesive 1 becomes its only stable guarantee. As the structural

adhesive 1 continues to age, it will be difficult to withstand the above loads, and the transparent part 2 will fall off from the

fuselage frame, resulting in accidents.

[0009] 5. During the flight, due to the continuous increase of the internal and

external pressure difference, the transparent part 2 will produce outward arching deformation and directly tear the edge of the sealant 1, so that there will be a gap between the edge of the sealant 1 and the transparent part 2. As the number of flights continues to accumulate, the gap between the edge of the sealant 1 and the transparent part 2 will gradually expand until the sealant 1 fails, which will cause

moisture to continuously penetrate into the interior of the transparent part 2, corrode its internal structural

adhesive, and accelerate its aging; and fix the transparent The bolts of part 2 will also loosen due to repeated deformation of transparent part 2, which will reduce the service life of transparent part 2 and become a great safety

hazard[0010] 6. When the

polyurethane interlayer on the edge of the laminated transparent part 2 is eroded, it will change from transparent to milky white translucent, even yellow, cracked and delaminated, resulting in the conductive strips in the interlayer being stripped from the glass surface or even At the same time, an arc occurs at the junction between the inner edge of the conductive strip and the

heating film. The local overheating generated by the arc will cause the conductive strip to

change color and the anti-

icing heating system to fail. In more serious cases, the outer transparent part 2 will be broken.

[0011] 7. If Figure 2-Figure 4 As shown, a

metal part 3 is added during installation to increase the fastness of the installation structure of the transparent part 2. After the deformation of the part 2, the

metal part will become a lever fulcrum to destroy the internal stress state of the edge of the transparent part 2, causing cracks on the edge of the transparent part 2 and even directly causing damage to the edge of the transparent part 2

If there is no

effective solution to the above problems, it will be difficult to overcome related technical problems such as the rapid aging of the sealant on the transparent parts of civil aviation aircraft windows, short service life, difficult unit detection, and unstable

moisture-proof sealing performance. The above problems still exist , the fastening and installation structure of the window transparent parts of civil aviation aircraft has also become a major problem for relevant technical personnel

[0032] However, with the progress of the times, the professional technologies of all walks of life are constantly being updated, and people's demand for civil aviation aircraft is also increasing. However, the technology that can effectively improve the safety and economy of the transparent parts of civil aviation aircraft windows has not yet been solved.

For such important problems affecting people's lives and property safety, there is no reasonable solution at present, and the present invention fills the gap in this field

Login to View More

Login to View More  Login to View More

Login to View More