Rigid structure system of large airship

A rigid structure and system technology, applied in the field of airship structure, can solve the problems of low efficiency of flight actuators, prominent stress concentration of the outer airbag, high stress level of the outer airbag, etc., to achieve good flight capability, simple force transmission path, and clear mechanical action Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Now in conjunction with accompanying drawing, invention will be further described.

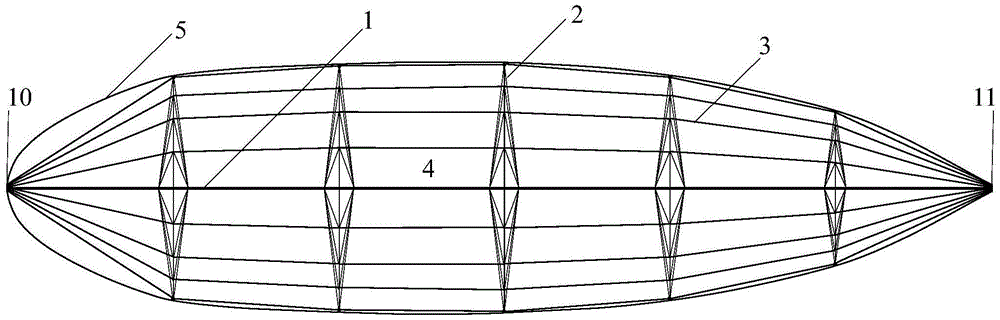

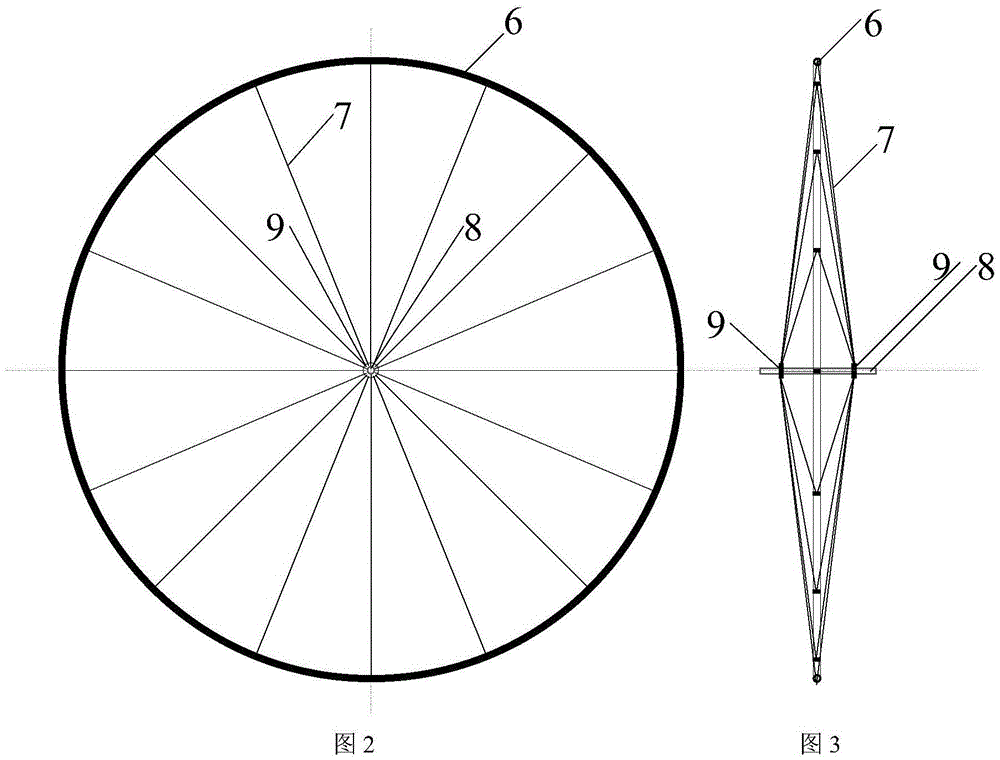

[0020] see figure 1 , figure 2 and image 3 , figure 1 , figure 2 and image 3 Shown is one embodiment of the invention. This embodiment is made up of ring pipe 6 made of carbon fiber, prestressed tie rod 7 made of carbon fiber, central tube 8 and tension fixed disk 9. It is composed of hub-shaped prestressed stiffening ring 2; by central mandrel 1, prestressed stiffening ring 2 and The longitudinal connecting rods 3 form an integral prestressed rigid structure system; the outer skin and the prestressed rigid structure system constitute the hull structure of the airship.

[0021] This embodiment includes a prestressed structural system 4 and a flexible outer capsule structure 5 . The prestressed structural system 4 is composed of a central mandrel 1 , a prestressed stiffening ring 2 and a longitudinal connecting rod 3 . The central mandrel 1 is composed of a hollow carbon fibe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com