Constructing method for threading pre-stress structure steel strands

A technology for prestressed structures and steel strands, applied in structural elements, building components, building structures, etc., can solve the problems of limited construction speed and scope of application, poor flexibility and yield, waste of steel materials, etc., to save raw materials. , good flexibility and flexibility, the effect of saving steel materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

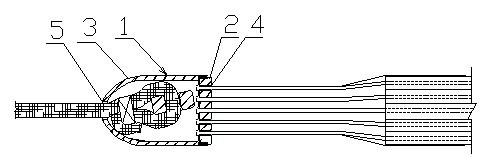

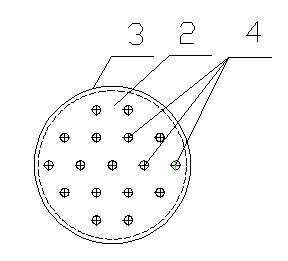

[0028] The construction method of the steel strand in the prestressed structure of the present invention passing through the bellows is characterized in that it comprises the following steps:

[0029] 1. According to the process design requirements and the requirements of the prestressed structure design, determine the number of steel strands that should be used, the number of steel strands in each bundle of steel strands, and carry out steel strand blanking processing;

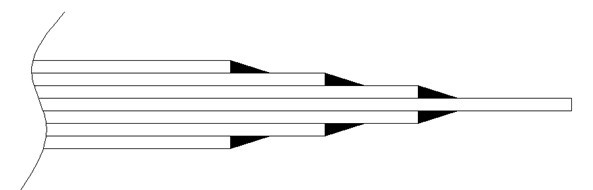

[0030] 2. When preparing each bundle of steel strands, strip and cut off the end steel wires (about 5-10cm) of each steel strand, leaving only one steel wire in the middle, that is, the front end of the steel wire is larger than the steel wire. The front ends of the other steel wires of the steel strand are exposed to a certain length (about 5-10cm), and the front ends of the other steel wires of the steel strand are flush or in a roughly flush position, and then the steel strands are braided according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com