Large-span hangar fringe truss prestressed structure system and construction method thereof

A technology of prestressed structure and construction method, which is applied to building components, building structures, roofs, etc., and can solve the problems of reducing the effective bearing external load of the supporting columns of the gate truss, difficulties in making non-circular cross-sections of the gate truss, and low material utilization. , to achieve the effect of improving the ability to resist external loads, reducing restraint internal forces, and increasing vertical support stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

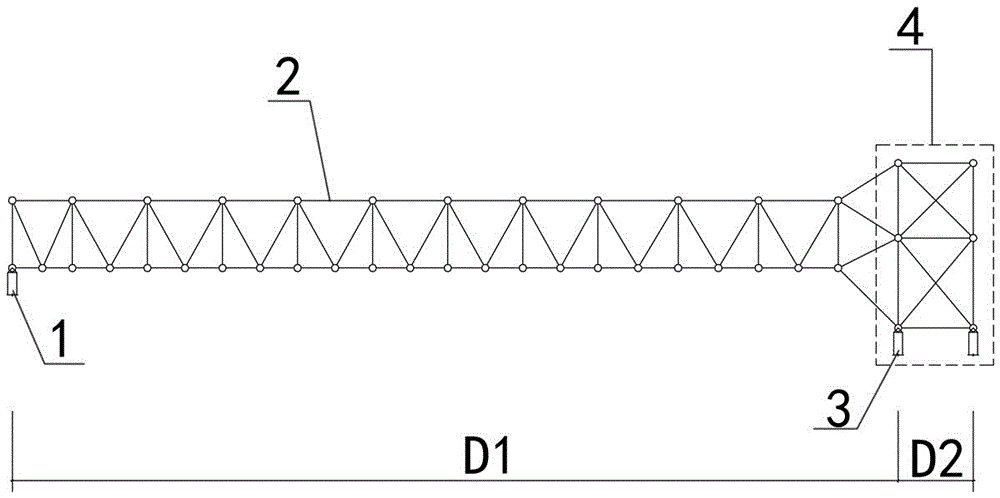

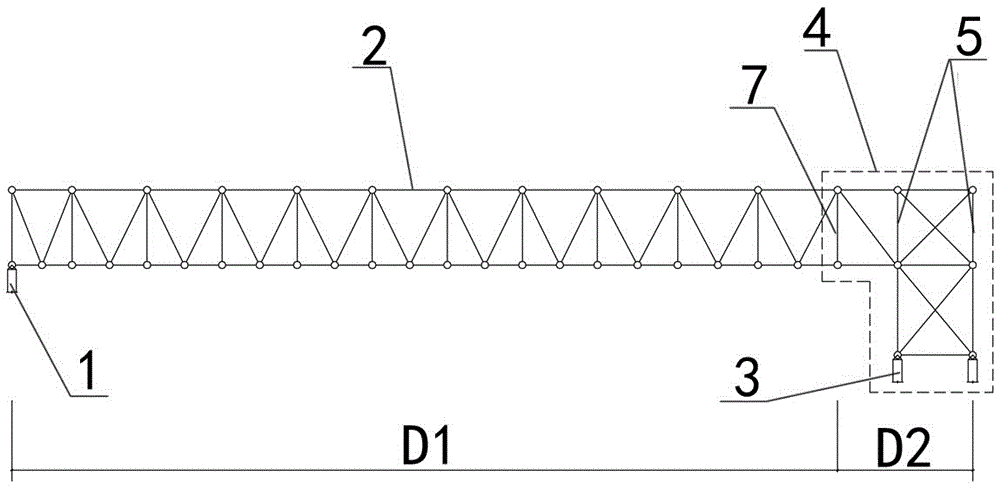

[0052] Embodiment one sees figure 2 As shown, the roof steel structure 2 is designed as a grid structure. This large-span hangar side truss prestressed structure system includes roof support columns 1 arranged at intervals along the three sides of the hangar, fixed on the top of the roof support column 1 The flat-plate grid structure, the gate truss support columns 3 which are located at the side of the open side of the roof support column 1 and arranged at intervals along the depth direction of the hangar, and the gate truss 4 fixed on the top of the gate truss support column 3, the gate The truss 4 is an irregular section space truss, the number of the upper chords of the gate truss 4 is more than the number of the lower chords, and the gate truss 4 includes the outermost truss 7 of the grid structure, that is, the outermost truss 7 is used as the gate truss One of the trusses is stressed, and the lower chord of the gate truss is provided with internal prestressed steel str...

Embodiment 2

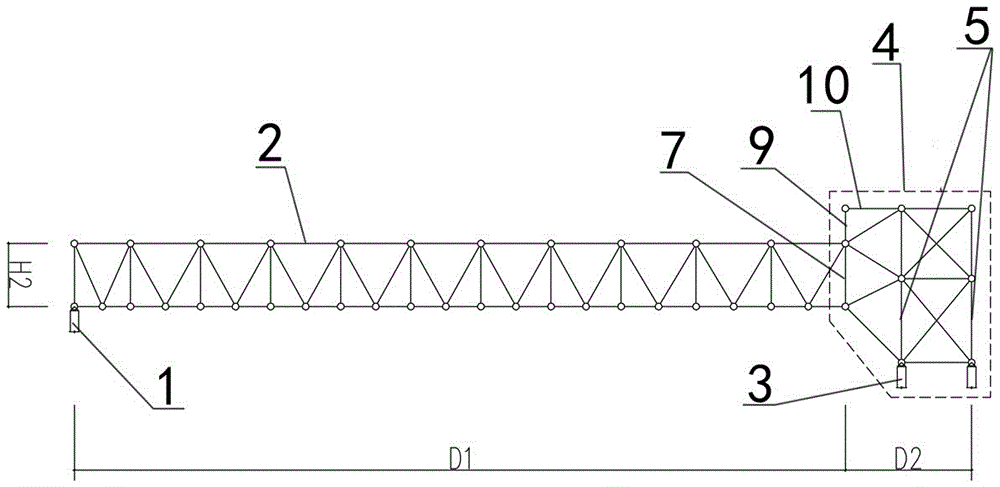

[0055] Embodiment two see image 3 As shown, the difference from Embodiment 1 is that the elevation of the gate truss 4 is higher than that of the roof grid, and the connecting truss includes the outermost truss 7 of the roof grid and the outermost truss 7 of the roof grid. The pressure shunt upper chord 8 added on the upper side of the outermost truss upper chord 7.1, the pressure shunt upper chord 8 is equal to the elevation of the prestressed double-layer truss upper chord 5.1 of the prestressed double-layer truss, and the pressure shunt upper chord The bar 8 is connected with the uppermost chord 7.1 of the outermost truss through the vertical web 9 , and the pressure shunt upper chord 8 is connected with the upper chord 5.1 of the prestressed double-layer truss through the horizontal web 10 .

[0056] see Figure 4-6 As shown, the width of the hangar is s, the depth of the roof grid is D1, and the height is H2, and the depth of the gate truss 4 is D2, and the height is H1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com