Method for testing grouting compactness degree of prestressed pore of bridge based on elastic-wave energy dissipation rate

A technology for grouting and testing methods for ducts, which is applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, which can solve problems such as affecting corrosion, unsatisfactory encapsulation of cement mortar and bolts, and endangering the safety of structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

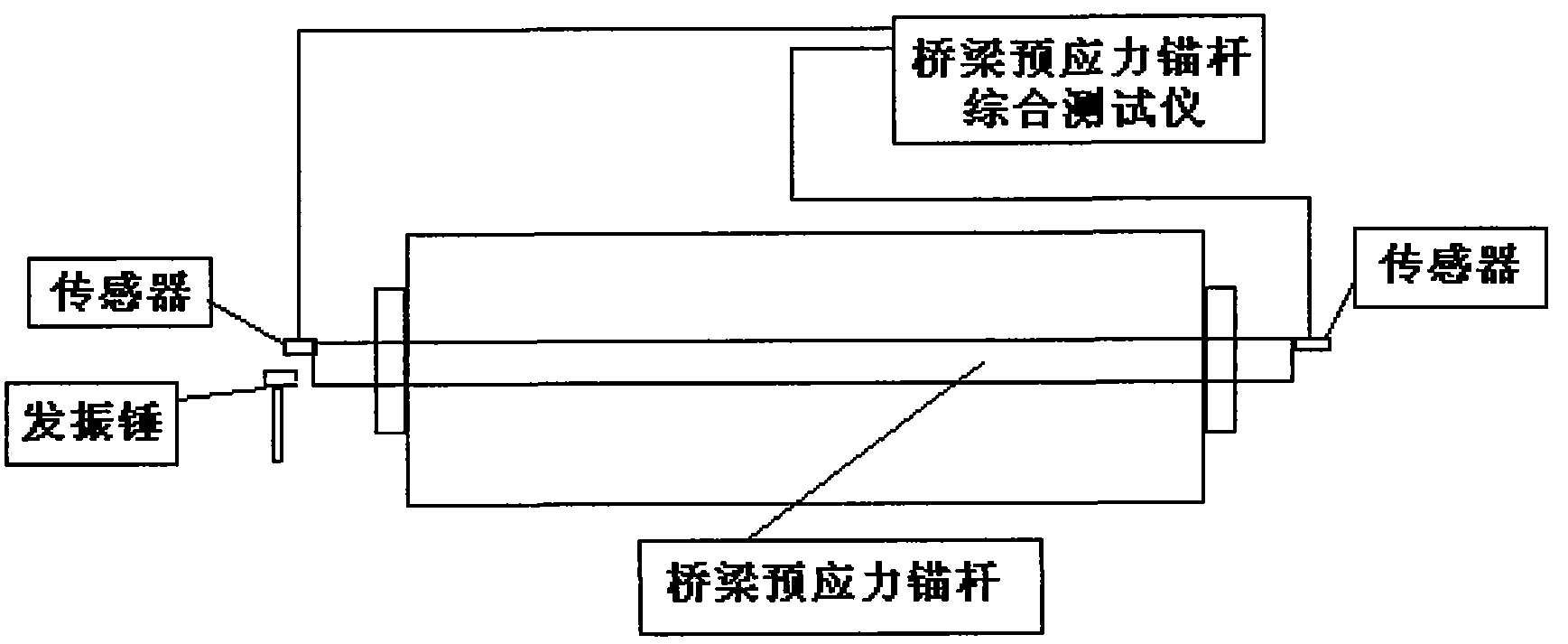

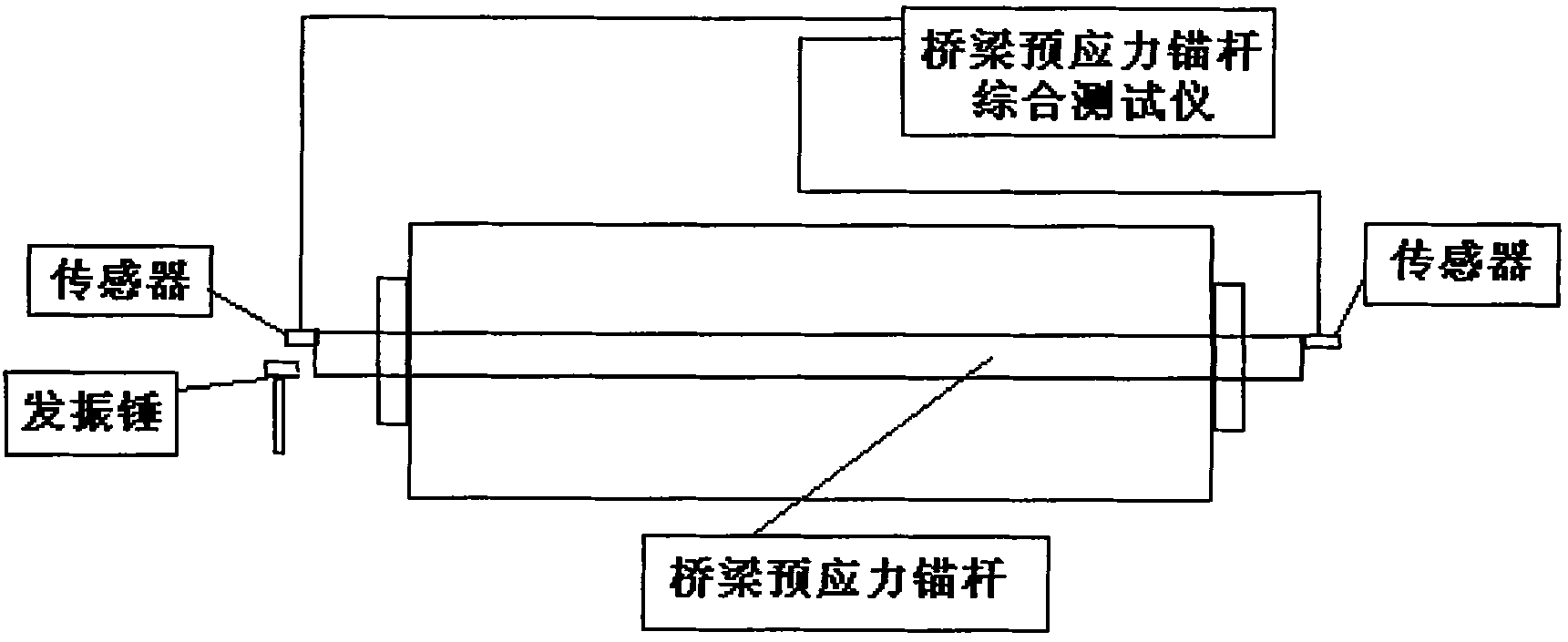

[0006] Refer to attached picture. The present invention is implemented according to the following steps: a. two or more sensors or ultrasonic probes are respectively installed on the end or end side of the two ends of the anchorage, and are connected to the tester with a signal cable; b. use a vibrating hammer Or the automatic device excites vibration at one end of the prestressed anchor of the bridge, and collects a set of test data; c. Under the same setting, excites vibration at the other end of the bridge prestressed anchor, and then collects a set of test data; d. The signal is processed to obtain the fluctuation characteristics of the signal, mainly the elastic wave energy dissipation rate; e. Using the fluctuation characteristic parameters, the instrument automatically calculates the grouting density of the bridge prestressed tunnel. The invention can eliminate the systematic error in the test to the greatest extent, and accurately test the elastic wave energy dissipati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com