Fan rotating speed control system and method for electric vehicle battery charger

A fan speed and control system technology, applied in engine control, pump control, machine/engine, etc., can solve problems such as inaccurate measurement, inconsistent fan speed, nonlinear resistance-temperature curve, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0121] In order to better understand the present invention, the content of the present invention will be further described below in conjunction with the accompanying drawings.

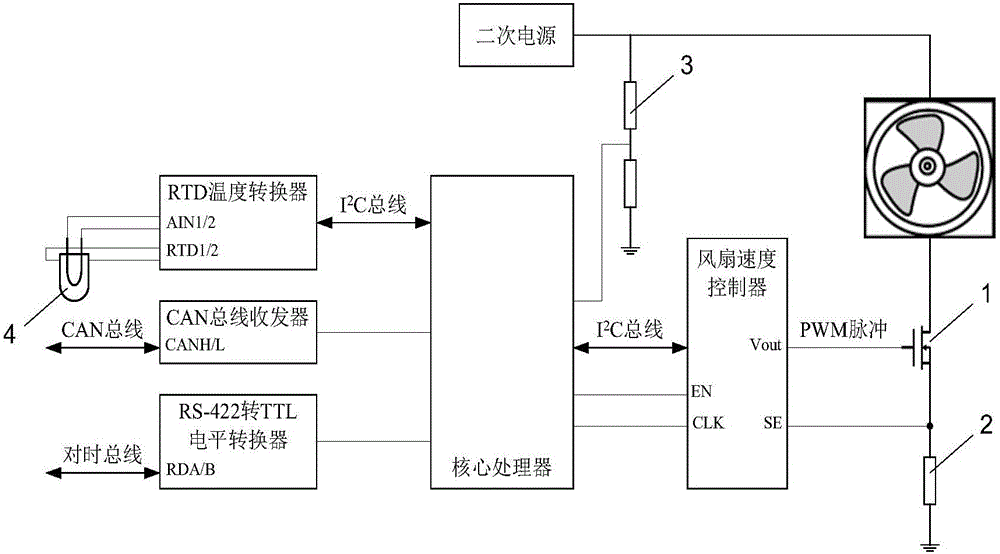

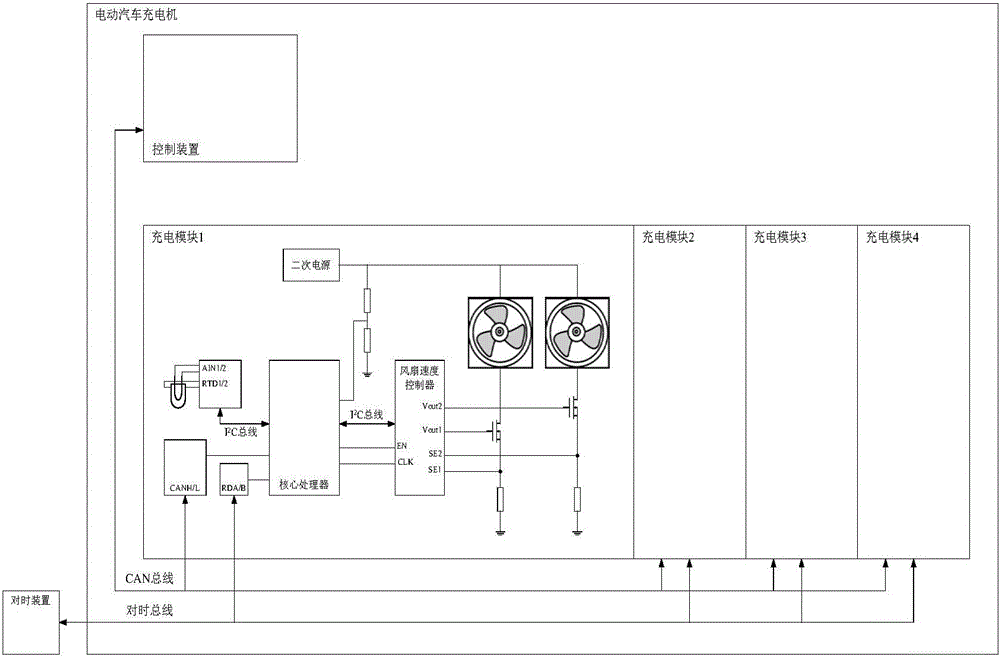

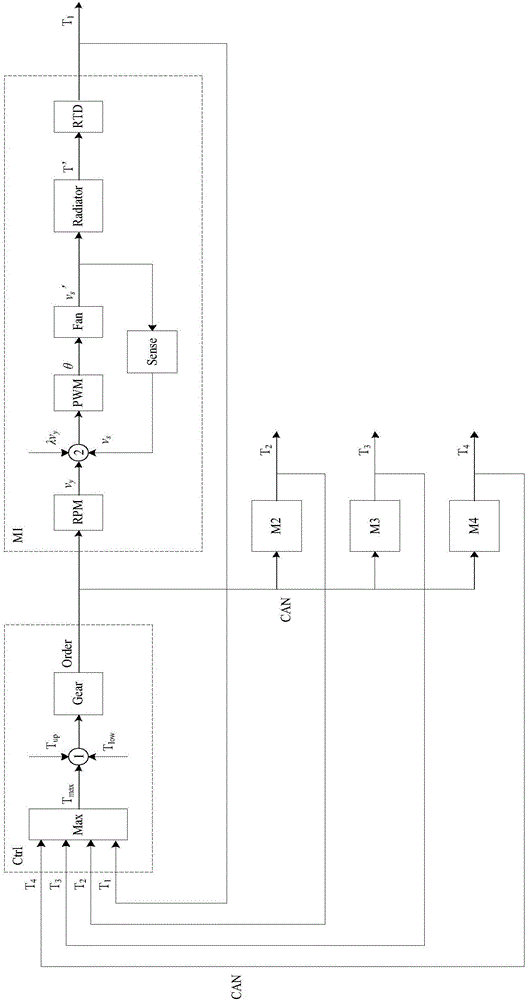

[0122] Such as figure 1 The fan speed control system shown in the first embodiment of the present invention is located in a charging module, including a fan control unit, a fan and a temperature measurement unit; the fan control unit includes a fan speed control circuit, a fan input voltage measurement circuit Rotate the control circuit synchronously with the fan.

[0123] The fan speed control system should share the core processor and CAN bus communication circuit with other control systems in the charging module.

[0124] The charging module core processor has the following technical details:

[0125] The core processor adopts a digital signal processor (DSP), and the DSP chip has powerful mathematical operation capabilities, and has a wealth of on-chip peripherals and interfaces, including CAN bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com