Laser radar calibration device and calibration method based on space-time transformation

A laser radar and calibration device technology, applied in the direction of radio wave measurement systems, instruments, etc., can solve the problems of poor calibration accuracy, harsh calibration environment requirements, difficult to meet, etc., to eliminate the impact of accuracy, wide range of calibration distance, overcome Difficult to install effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

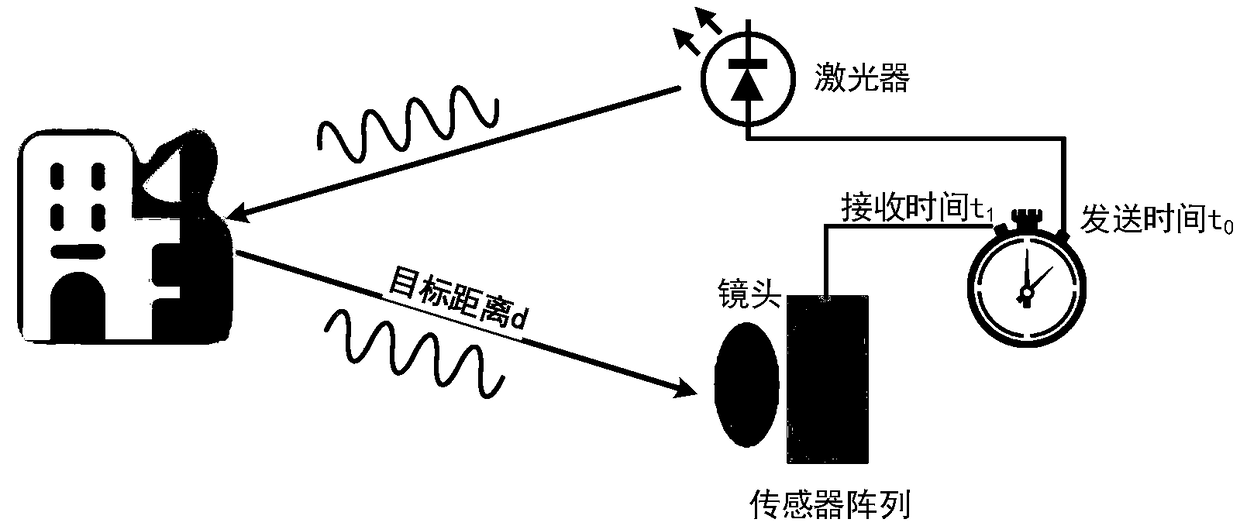

[0075] see figure 1 , ToF lidar ranging principle diagram, when ToF-based lidar starts ranging, it transmits signals to the target scene by controlling the laser, and the emission time is recorded as T 0 . After the signal is reflected by the target scene, it is transmitted to the sensor of the lidar and received by the sensor. The time when the sensor receives the signal is recorded as T 1 , the time difference between the transmitted signal and the received signal is (t 1 -t 0 ), combined with the speed of light c, the distance between the target scene and the lidar can be calculated:

[0076] d=c*(t1-t0) / 2

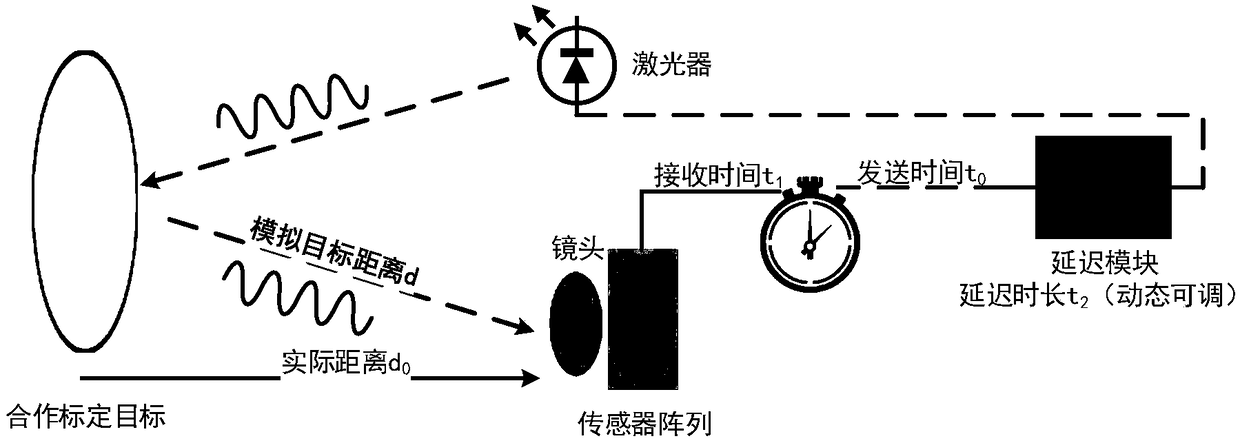

[0077] In order to make the calibration results more accurate, it is necessary to perform multiple calibrations at different distances. The traditional calibration method achieves calibration at different points by changing the actual physical distance between the cooperative calibration target and the 3D area array lidar. This calibration method requires a large T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com