Steel strand bundle-weaving and crossing construction method

A construction method and a technology of steel strands, which are applied in the field of braiding and threading of steel strands when tensioning prestressed anchors, can solve problems such as increased difficulty in threading, deviation of prestressed data, and deflection of beams. Achieve the effect of avoiding uneven stress on steel strands, overcoming operational errors, and improving construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

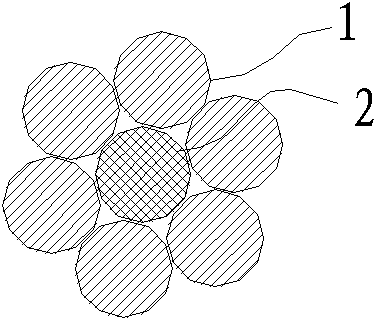

[0032] see figure 1 , the steel strand that the present invention needs to bundle is made up of a central steel wire 2 and six outer layer steel wires 1, and the six outer layer steel wires 1 are evenly distributed on the periphery of the central steel wire 2, and certainly the quantity of the outer layer steel wires can also be more.

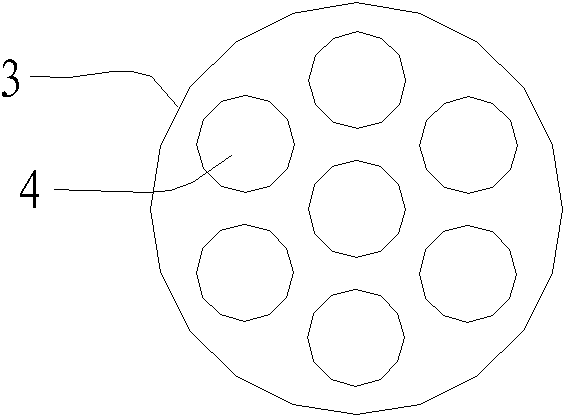

[0033] see figure 2 , the profiling comb plate and the sub-profiling comb plate used in the present invention are all circular plates, with through holes corresponding to the number of steel strands evenly distributed, and the profiling comb plate and the sub-profiling comb plate are only dimensioned Different, the diameter of the sub-profiling comb plate is 1 / 3 of the diameter of the profiling comb plate, figure 2 Taking the profiling combing board 3 as an example, there are evenly distributed through holes 4 corresponding to the number of steel strands, that is, seven through holes.

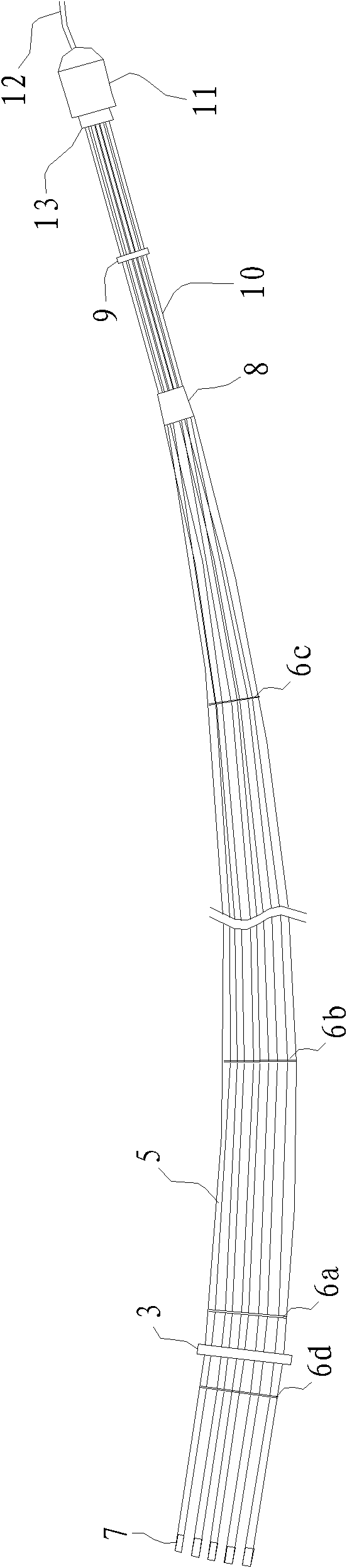

[0034] see image 3 , when carrying out steel strand ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com