Driller support device

A technology for supporting devices and drilling rigs, which is applied in the directions of supporting devices, drilling equipment, earthwork drilling, etc., to achieve the effects of reducing the size of modular structural parts, reducing the difficulty of disassembly, and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

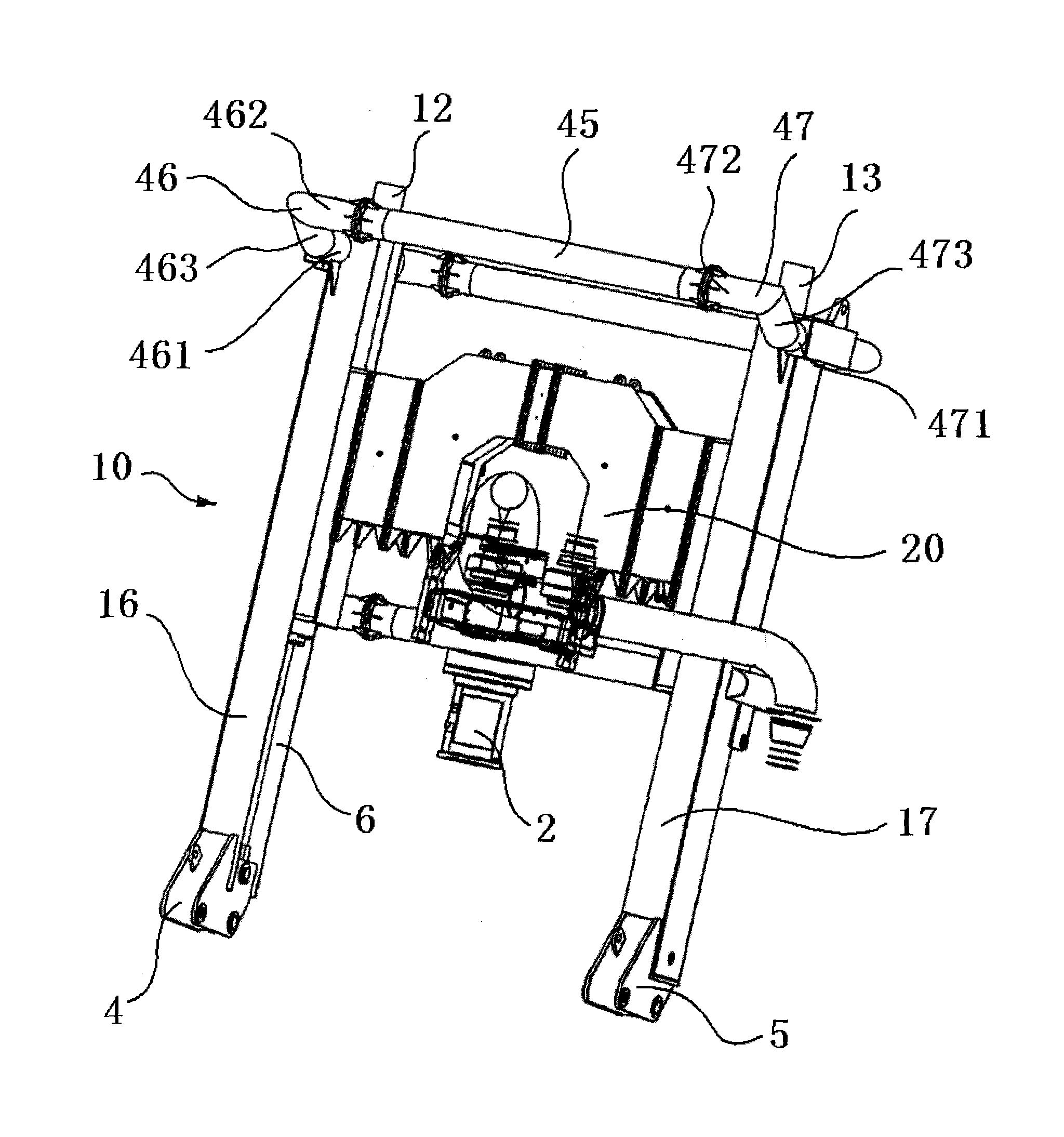

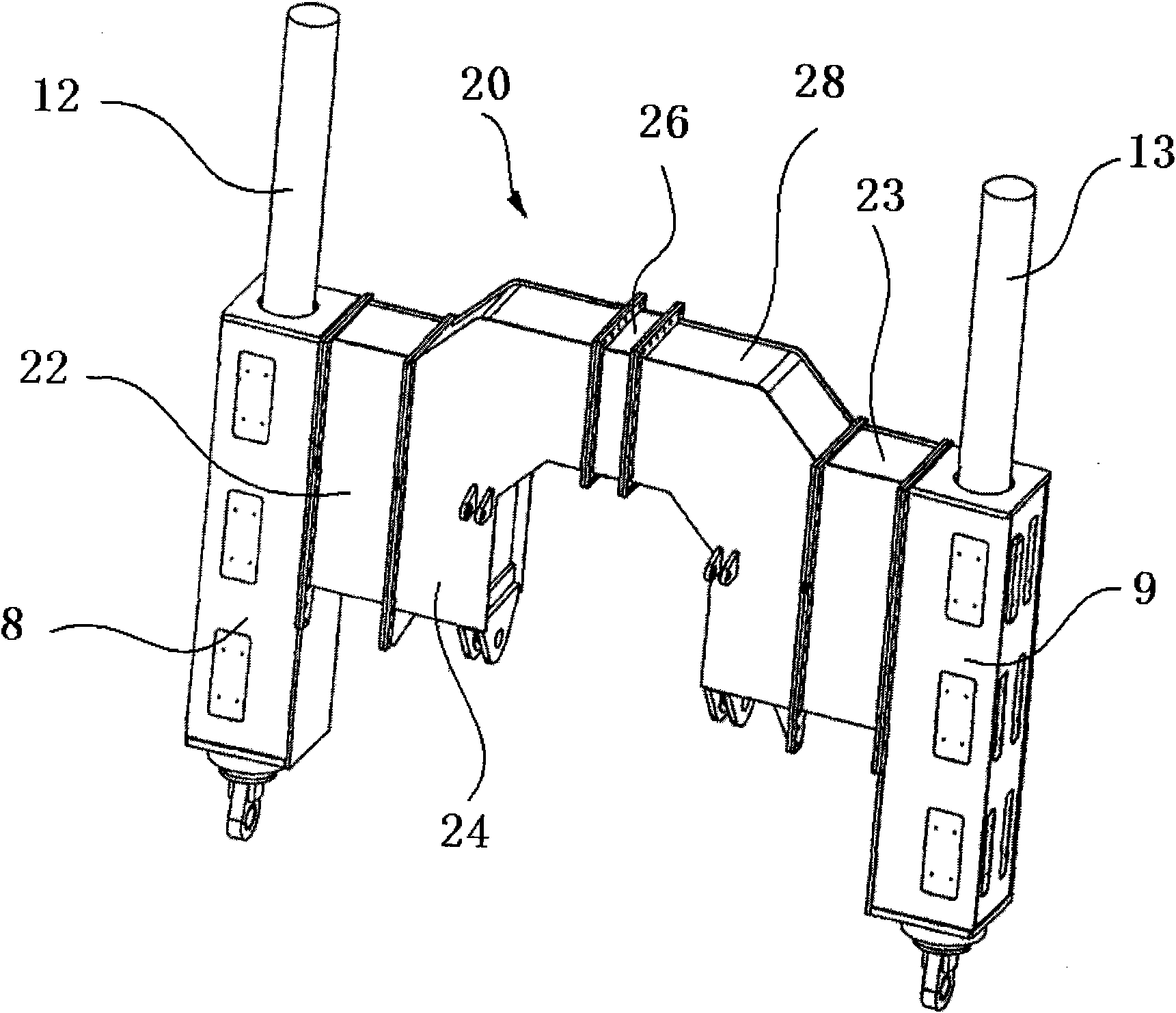

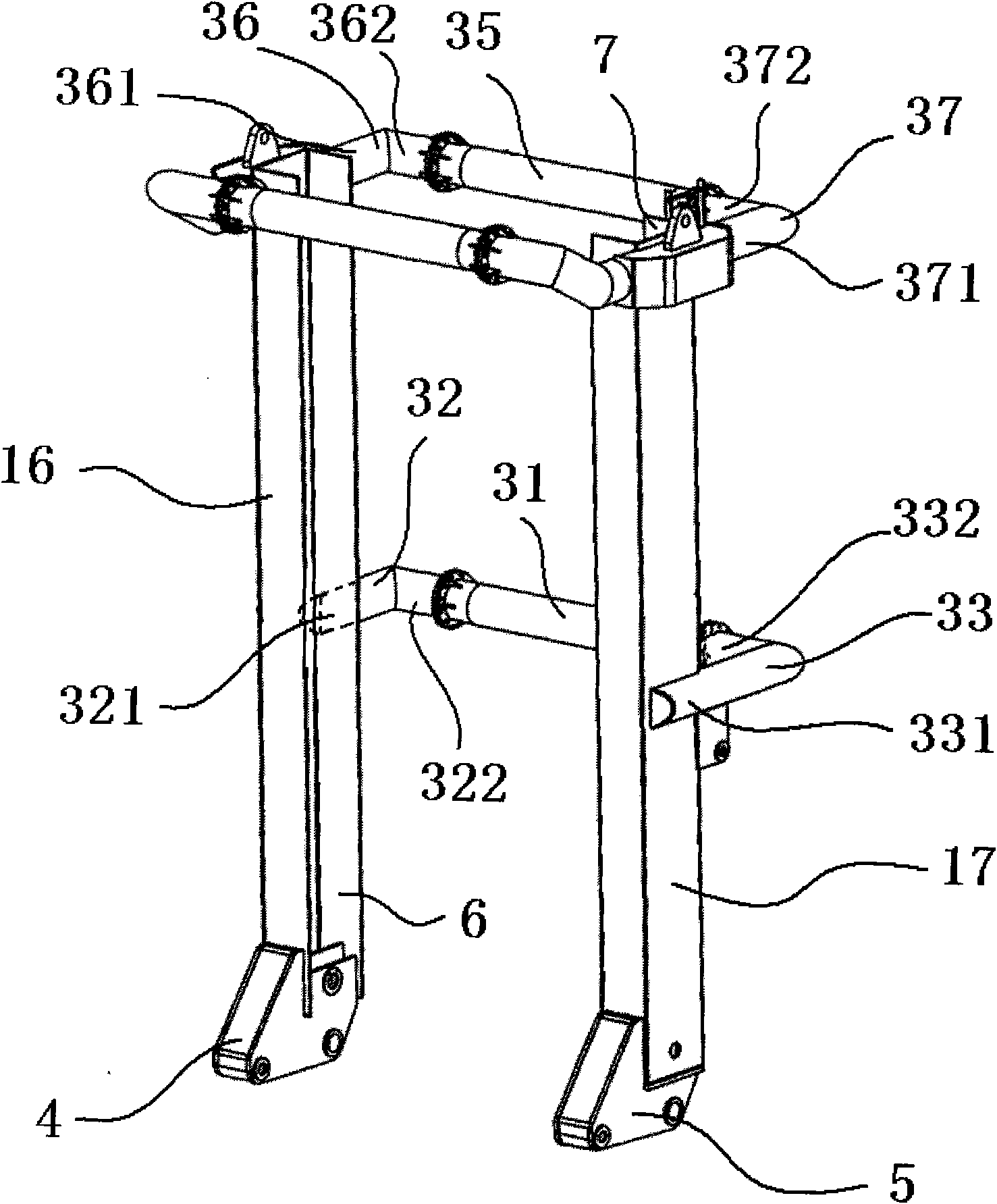

[0022] as attached Figure 1~3 As shown, in the embodiment of the drilling rig supporting device 10 provided by the present invention, the power head 2 is detachably installed on the carriage 20 . The carriage 20 can move up and down along the left mast 16 and the right mast 17 . Be provided with left chute 6 in left mast 16, be provided with right chute 7 in right mast 17, be provided with left slide cylinder 12 near left chute 6, be provided with right slide cylinder 13 near right chute 7.

[0023] In the embodiment provided by the present invention, such as figure 1 As shown, the left chute 6 in the left mast 16 has a U-shaped cross section, and the left slide cylinder 12 is located in the recessed part of the left chute 6 with a U-shaped cross section, and the right chute 7 in the right mast 17 has a U-shaped cross-section, the right slide cylinder 13 is located in the concave part of the right chute 7 with U-shaped cross-section. One end of the left mast 16 and the ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com