Heat exchange surface coating heat transfer performance testing system

A heat transfer performance and testing system technology, applied in the direction of material thermal development, etc., can solve the problems of deviation between the design value and the actual value of the heat transfer efficiency of the heat exchanger, inability to fully obtain the result performance test, limit the heat transfer performance test of the coating, etc. , to achieve the effects of accurate testing, good stability, high-cost surface modification technology, and simple processing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

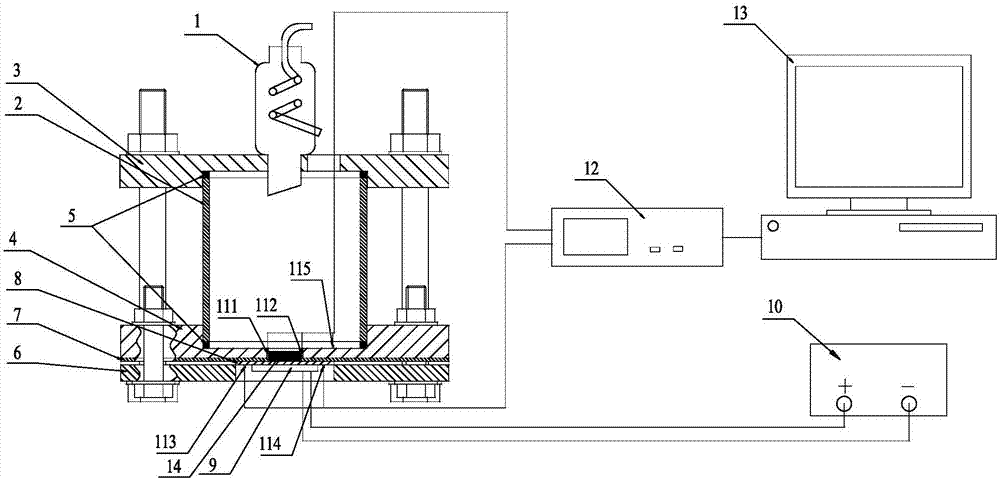

[0034] to combine figure 1 , a heat transfer performance test system of the heat exchange surface coating of the present invention is composed of a condenser 1, a boiling pool, a heater and a data acquisition system.

[0035] The condenser 1 communicates with the boiling pool, and is specifically connected to the through hole in the middle of the upper cover plate 3, and is used to collect the working fluid when the working fluid in the housing 2 boils, and the gas condenses and flows back into the boiling pool, and the upper cover plate 3 is another The opening is connected to the outside world, and the air pressure in the boiling pool is kept stable during the test, and always maintains an atmospheric pressure.

[0036] The boiling pool includes a housing 2 , an upper cover 3 , a lower cover 4 , a sealing gasket 5 , a bottom pressing plate 6 , a heat-insulating silicone pad 7 and a heat-conducting patch 8 . The housing 2 is transparent acrylic, the housing 2 is installed be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com