Bolster of express railway freight car bogie

A technology of railway freight cars and bogies, which is applied in the field of bolsters of fast railway freight car bogies, can solve the problems of not being able to adapt to the suspension rod system traction rod device, the installation interface of the center disc, etc., and achieve the effect of simple structure and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

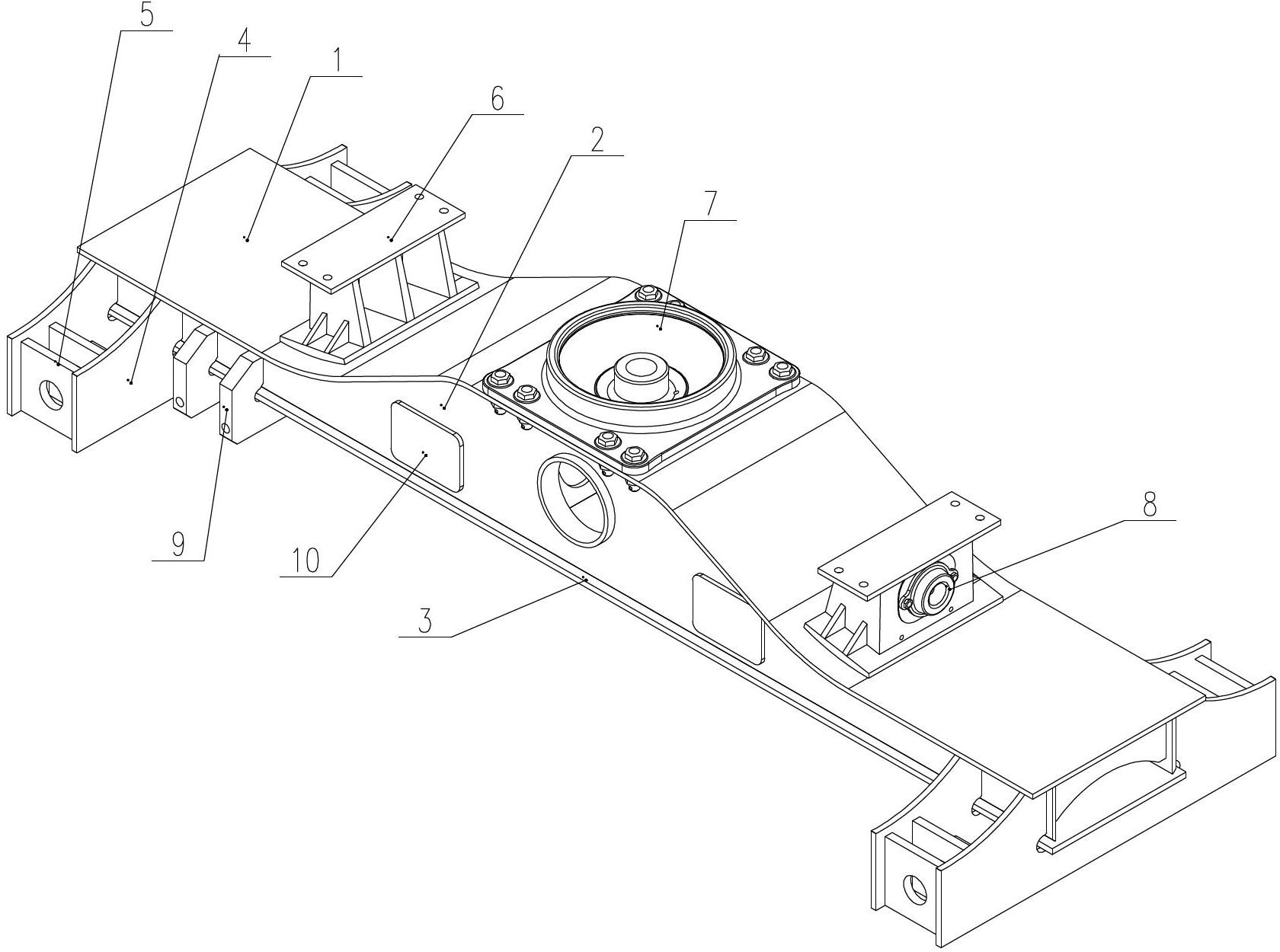

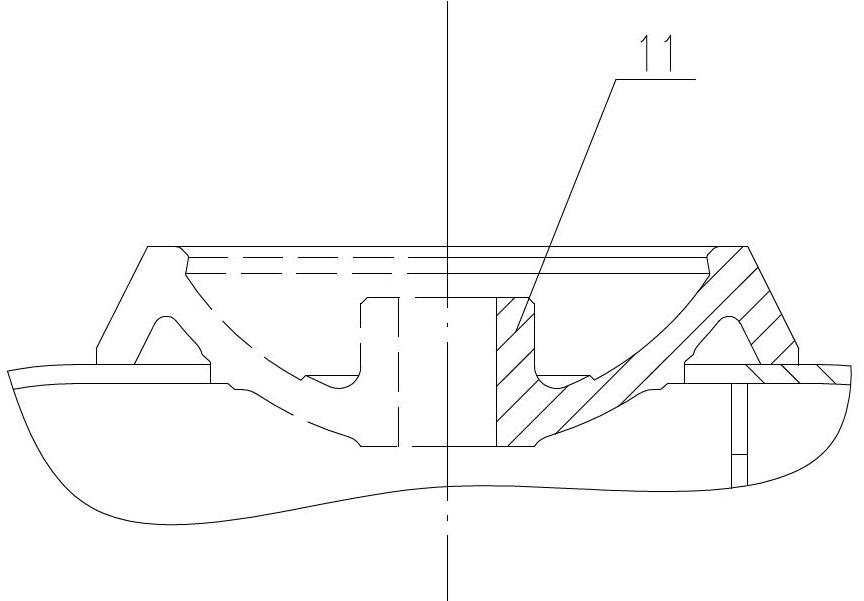

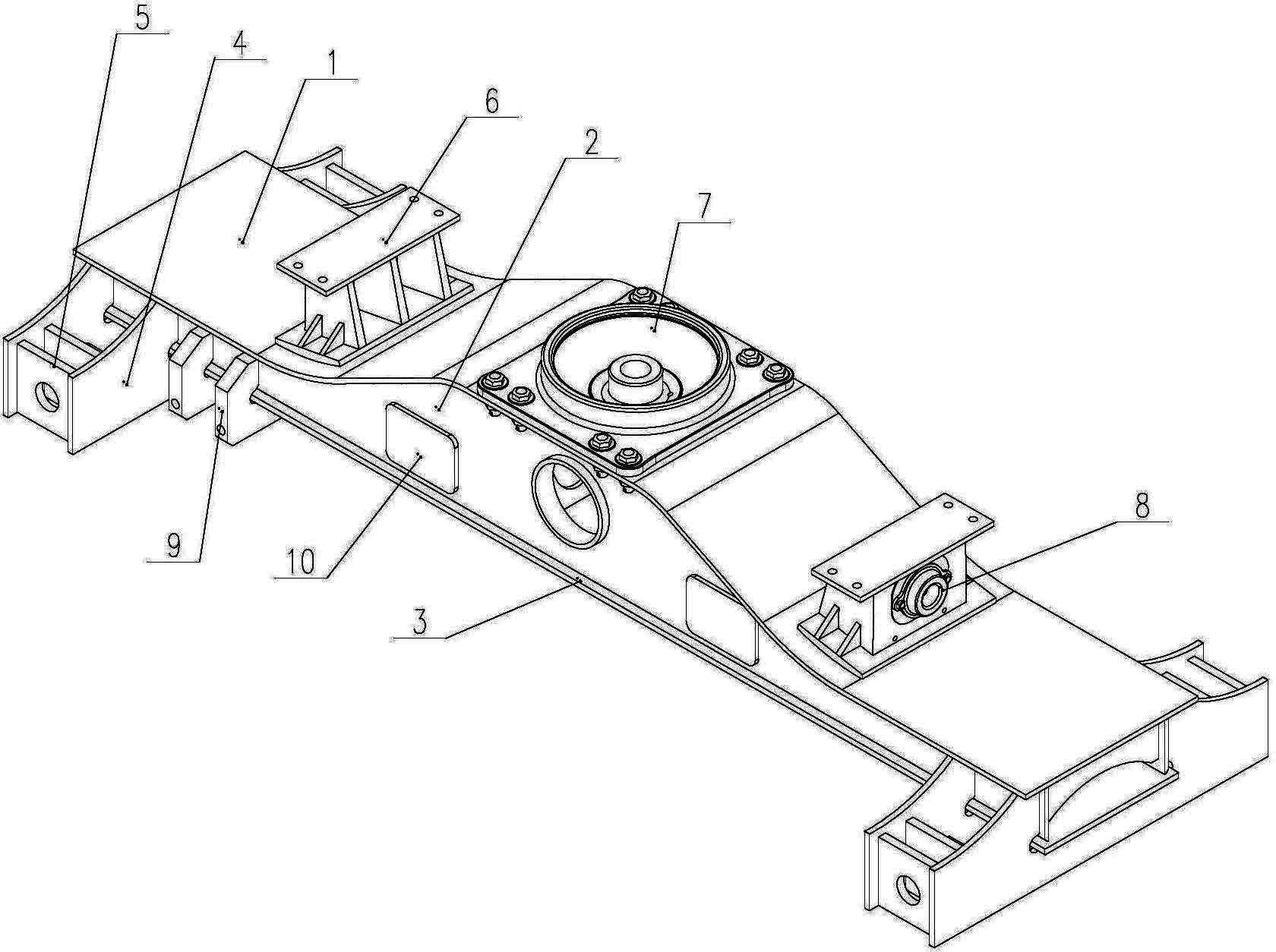

[0017] A bolster of a fast railway freight car bogie, combined with figure 1 , figure 2 , including bolster upper cover plate 1, bolster web plate 2, bolster lower cover plate 3, bolster end plate 4, the bottoms of the two bolster web plates 2 are symmetrically arranged on the bolster lower cover plate 3, two The upper part of the bolster web 2 is provided with a bolster upper cover plate 1, and the middle part of the bolster upper cover plate 1 is provided with a spherical hole. Side support mounting seats 6 are provided on both sides of the upper end surface of the upper cover plate 1, and lateral elastic stoppers 8 are provided on the side bearing mounting seats 6. The upper cover plate 1 of the bolster is connected with the end plate 4 of the bolster, and the end plate 4 of the bolster Boom seat 5 under the bolster is arranged on the top, and lon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com