High-strength, deformation-resisting and collapsible precoated sand and preparation technology thereof

A technology of anti-deformation and coated sand, applied in manufacturing tools, casting equipment, metal processing equipment, etc., can solve the problems of low gas generation, easy collapse, good fluidity, etc. The effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

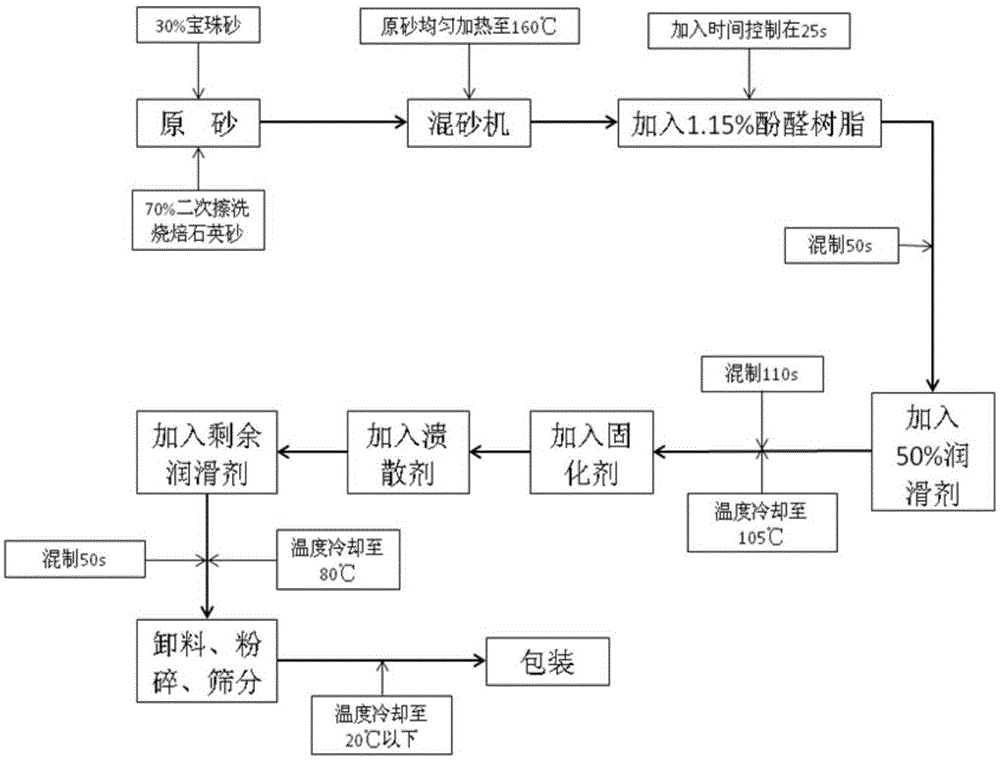

[0026] Embodiment 1 Preparation of coated sand of the present invention

[0027] 1) Raw material preparation: sand, phenolic resin, curing agent, lubricant and disintegrating agent. Among them, the original sand is composed of 30% pearl sand and 70% quartz sand, the amount of phenolic resin added is 1.15% of the original sand mass, the amount of curing agent added is 13% of the amount of phenolic resin added, and the amount of lubricant added 0.1% of the mass of the original sand, and the addition of the disintegrating agent is 0.2% of the mass of the original sand.

[0028] 2) First put the raw sand composed of pearl sand and quartz sand into the sand mixer, mix and heat to 160°C;

[0029] 3) Then add phenolic resin, the addition time is 25s, and the mixing time is 50s;

[0030] 4) Add half of the lubricant, and the mixing time is 110s;

[0031] 5) Lower the sand temperature to 105°C, add the curing agent, the remaining half of the lubricant and the disintegrating agent, a...

Embodiment 2

[0034] Embodiment 2 Comparison of coated sand of the present invention and other existing products of the same type

[0035] There are three types of sand used in this comparative experiment, namely:

[0036] Coated sand A: the existing same type of coated sand (YKS-BH, Chongqing Changjiang Modeling Materials (Group) Co., Ltd.);

[0037] Coated sand B: Improved coated sand (increase the content of phenolic resin on the basis of coated sand A to improve the bending strength at room temperature);

[0038] Coated sand C: the coated sand obtained in Example 1;

[0039] (1) Performance comparison, the test standard refers to the industry standard JB-T8583-2008 (results are shown in Table 1);

[0040] Table 1 performance comparison

[0041]

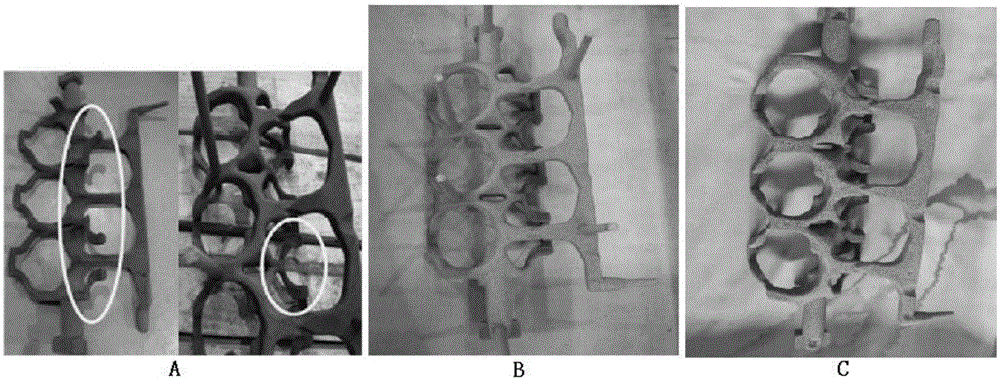

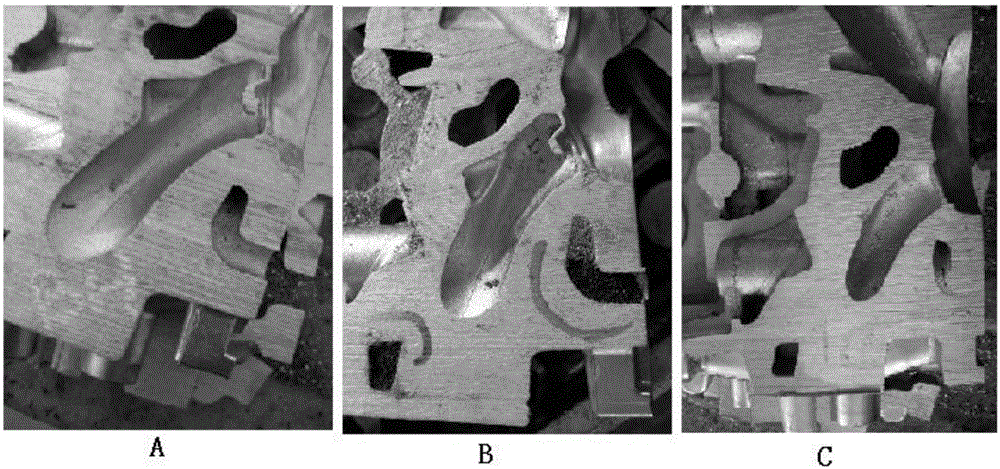

[0042] According to the test results (Table 1), the room temperature flexural strength and thermal flexural strength of the improved coated sand B and the new coated sand C are significantly higher than those of the existing same type of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com