Dimension correction device in large double-curved surface plate part processing and method thereof

A part processing and hyperboloid technology, which is used in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of large vacuum adsorption platforms that are not fixed firmly and the stress of hole positioning cannot be released.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

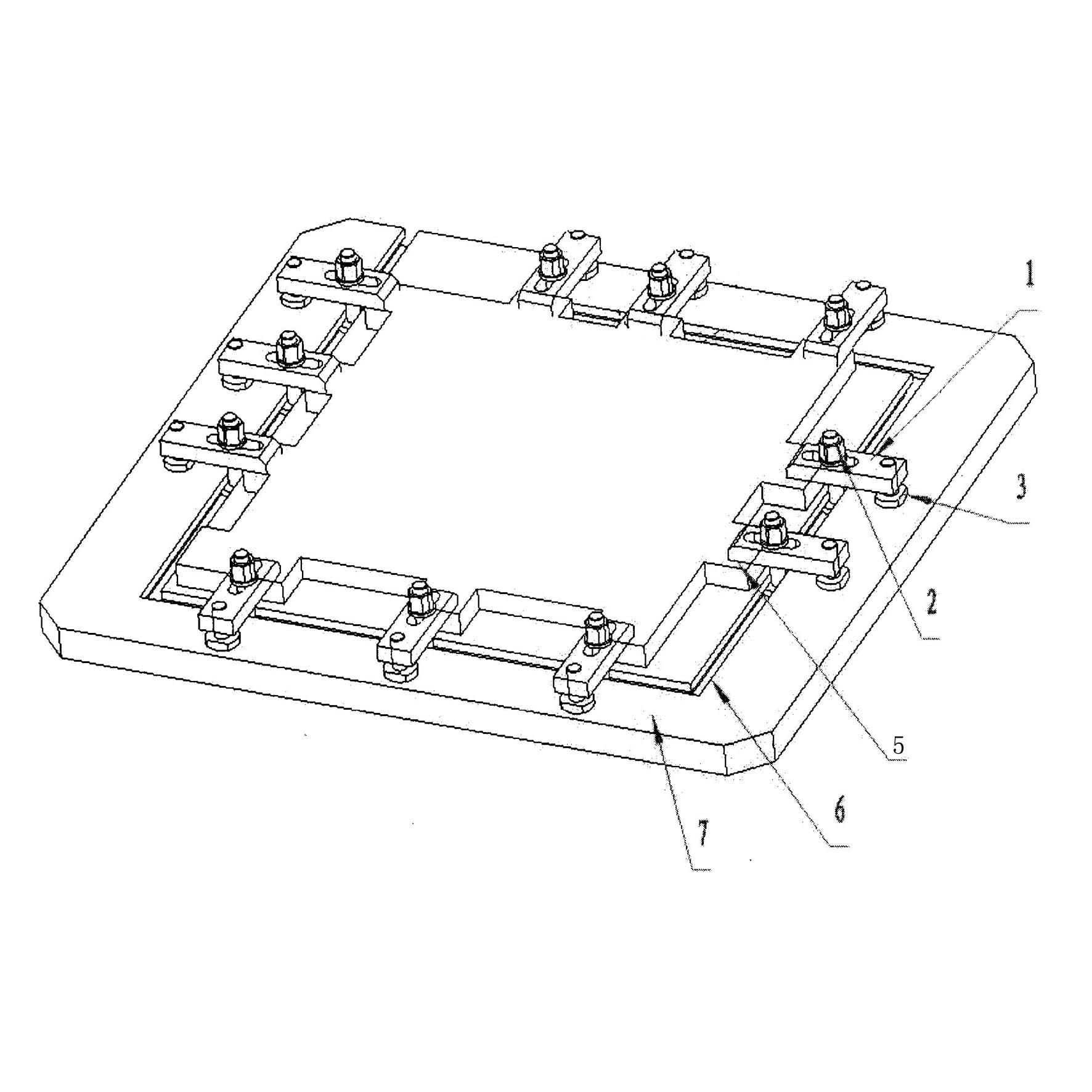

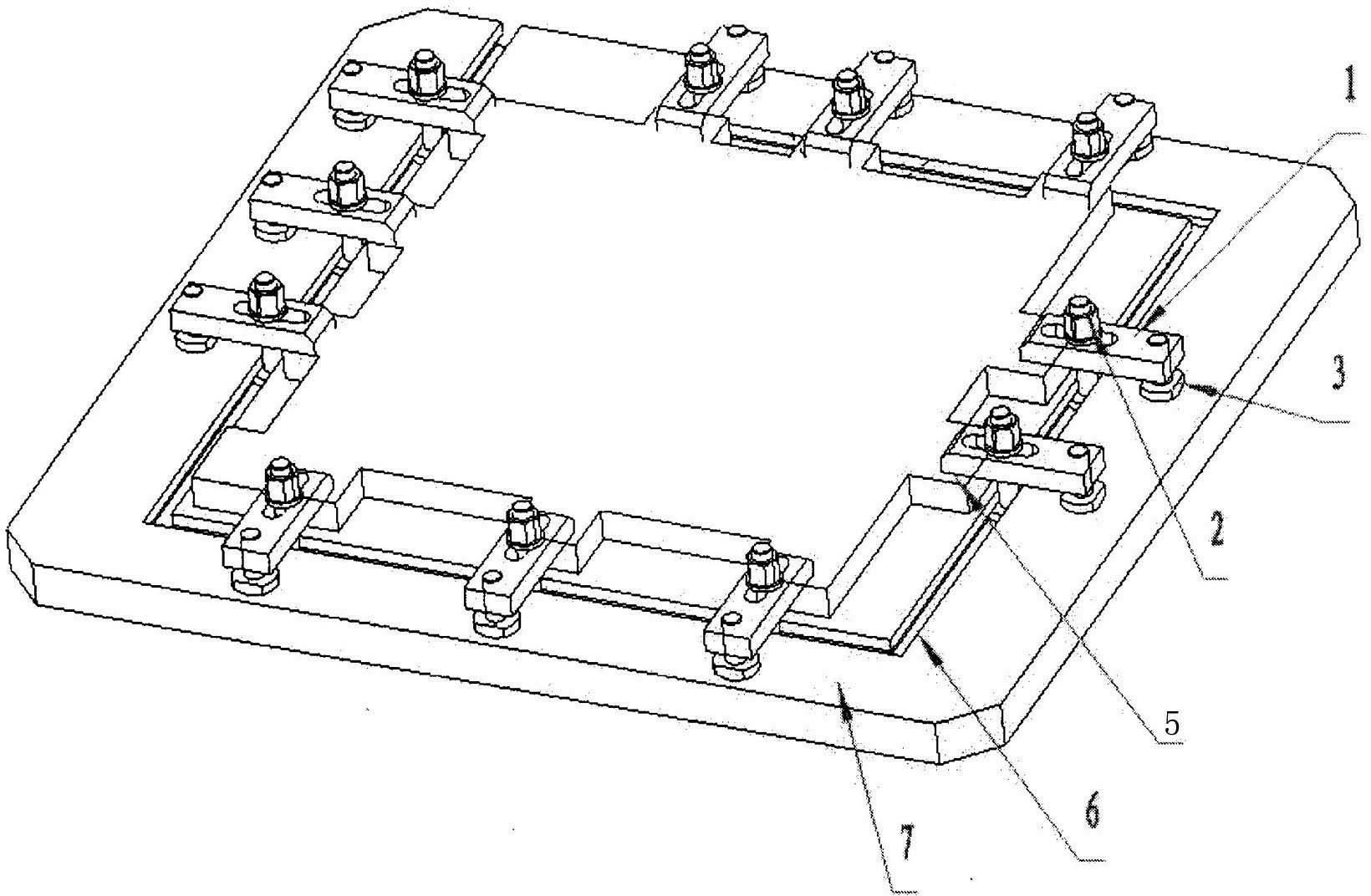

[0014] like figure 1 As shown, a size correction device in the processing of large-scale hyperboloid plate parts is provided with a rectangular T-slot 6 on the upper surface of the milling machine table 7, and a plurality of connecting bolts 2 are arranged in the T-slot 6; One end of the pressing plate 1 is provided with a long hole, and the other end is provided with an inverted support bolt 3, wherein the long hole is connected with the connecting bolt 2, and the bottom surface of the support bolt 3 is in contact with the surface of the milling machine table 7.

[0015] The calibration method using the dimension calibration device in the processing of large-scale hyperboloid plate parts includes the following steps:

[0016] 1) Multiple process bosses 5 are milled around the outer edge of the large hyperboloid plate parts to be processed, and the spacing between each adjacent process boss is 200~300mm;

[0017] 2) Place the processed large-scale hyperboloid plate parts with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com