Clamping type integral shrinking and overturning climbing robot

A clamping and robotic technology, which is applied in the field of climbing robots, can solve the problems of high labor intensity, high degree of danger, and difficulty in obtaining reliable guarantees for personal safety, etc., to achieve large clamping force, reduce power loss, reduce Effect of Small Longitudinal Displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

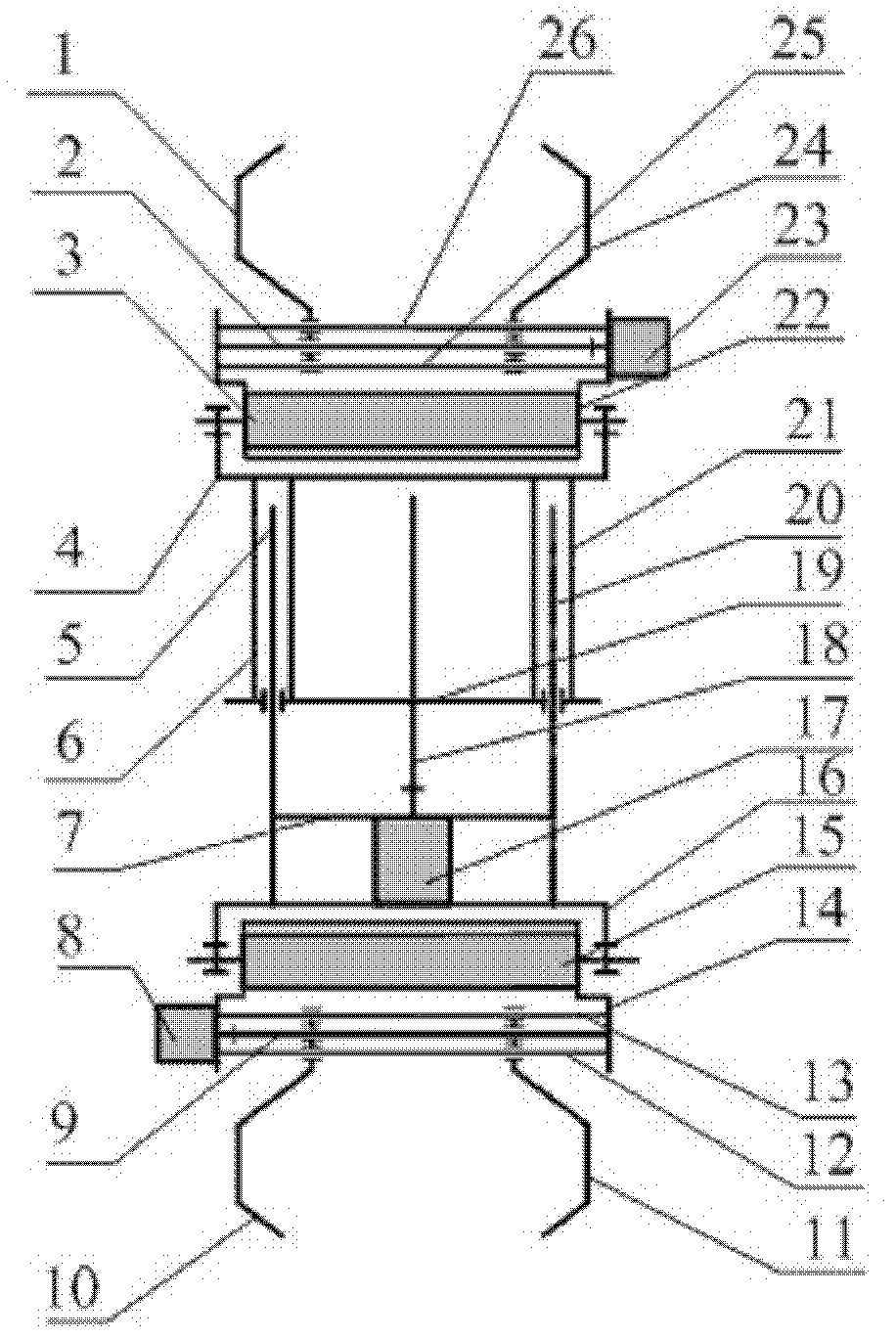

[0021] The present invention is described in more detail below in conjunction with accompanying drawing example:

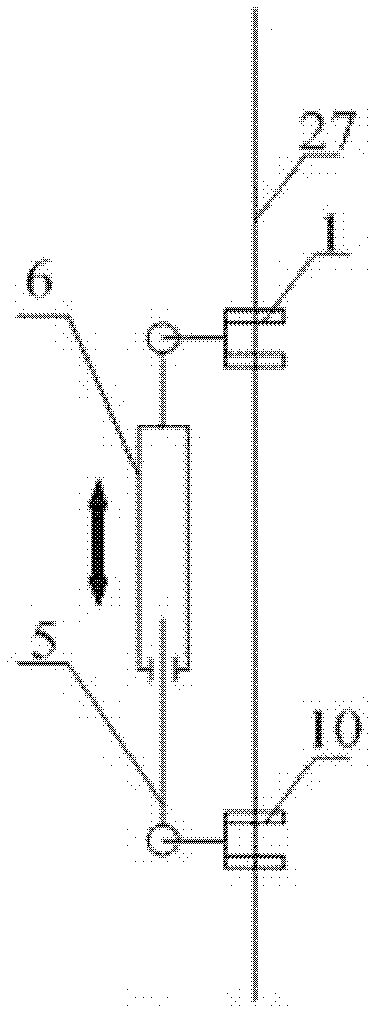

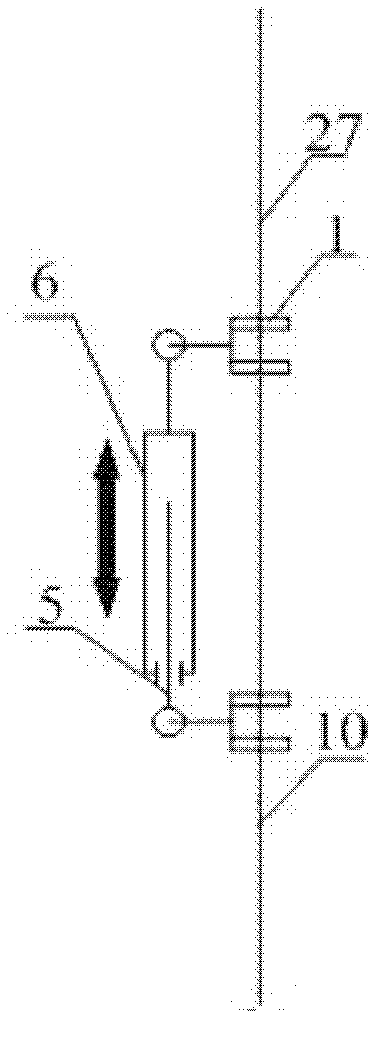

[0022] combine figure 1 ~6, the parts that the present invention comprises: robot mainly is by clamping claw 1,10,11,24, telescoping motor 17, overturning motor 3,15, claw clamping motor 8,23, claw lead screw 2, 9, leading screw 18, overturn frame 4,16, telescoping mechanism 5,6,20,21 form.

[0023] The present invention adopts the following technical scheme: the clamping part is composed of the clamping claw I1, the clamping claw IV22, the claw screw I2 and the clamping motor II21. Clamping jaw I1 and clamping jaw IV24 adopt sliding fit installation method with guide shaft III25 and guide shaft IV26, see figure 1 . The clamping motor frame II22 is fixedly connected with the overturning motor I3. The clamping motor II23 is installed at the center of the clamping motor frame II22 see figure 1 And it is fixedly connected with the claw lead screw I2 through a sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com