Pneumatic clamping mechanism

A clamping mechanism and pneumatic technology, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems of complicated production and complex overall structure, and achieve the effect of large clamping range, simple overall structure and simple mechanical movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

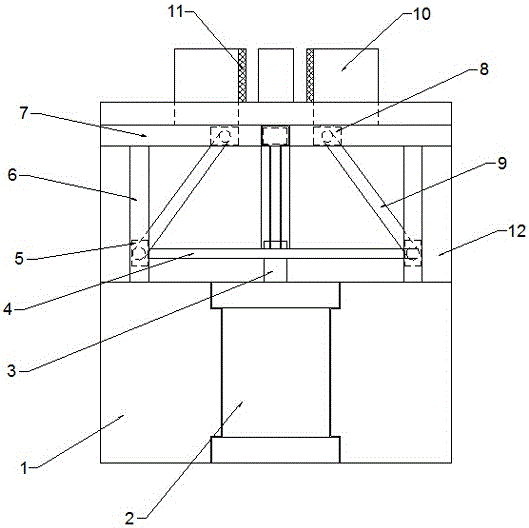

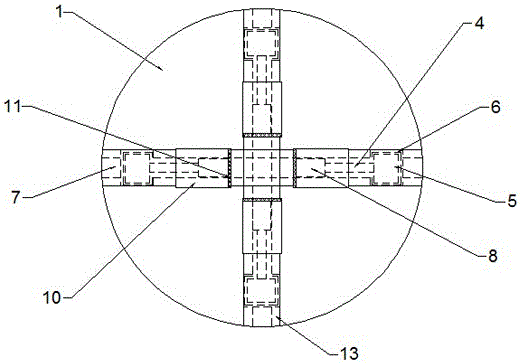

[0017] Such as figure 1 with figure 2 As shown, the present invention discloses a pneumatic clamping mechanism, which includes a chuck body 1, a cylinder 2 arranged inside the chuck body 1, a clamping mechanism and a guiding mechanism.

[0018] The chuck body 1 is in the shape of a circular column, with a cavity 12 for the guide mechanism on one side, a through hole for the cylinder 2 in the middle of the other side, and four chutes for the clamping mechanism at the end 13, the chute 13 communicates with the cavity 12.

[0019] The cylinder 2 is arranged in the through hole of the chuck body 1, the piston rod 3 points to one side of the cavity 12, two push rods 4 are connected to the piston rod 3, and a slider group A5 is respectively arranged at both ends of the push rod 4.

[0020] The clamping mechanism includes clamping blocks 10 nestedly fitted in the chute 13 , each clamping end of the clamping blocks 10 is provided with a rubber anti-skid pad 11 , and the bottom end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com