Large bar chamfering machine tool

A machine tool and chamfering technology, which is applied to turning equipment, turning equipment, metal processing equipment, etc., can solve the problems of high labor intensity, high cost of labor, low production efficiency, etc., and achieve compact structure, good safety performance, Adjust the effect of fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following descriptions are only preferred embodiments of the present invention, and do not limit the scope of the present invention.

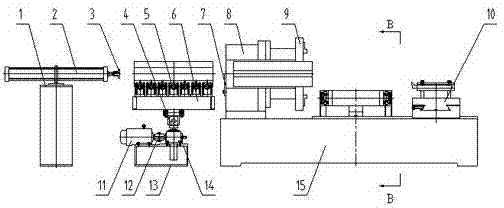

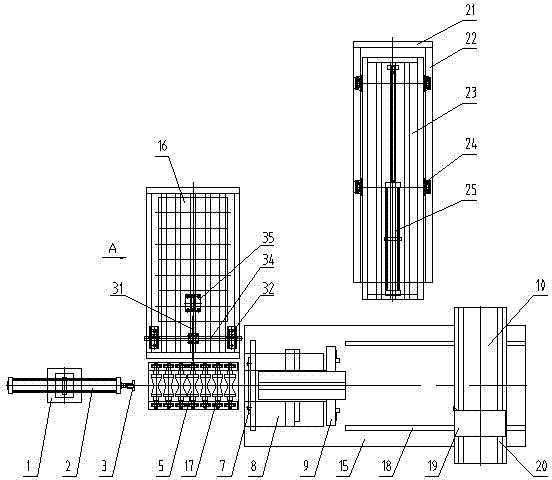

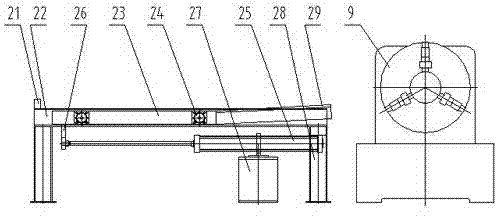

[0039] example, see attached figure 1 , 2 , 3, 4, 5, 6, 7, a large bar chamfering machine tool, including a bed 15, a machine tool headstock 8 mounted on the front end of the bed 15, mounted on the machine tool headstock 8 The three-jaw chuck 9, the headstock of the machine tool 8 is provided with a main shaft through hole, and a semicircular die seat is installed inside the main shaft through hole. The semicircular die seat 7 has various specifications according to the needs of production. 7 corresponds to a blank bar of a certain diameter, and the semi-circular die base 7 with a smaller radius can be set inside the semi-circular die base 7 with a larger radius, layer by layer, and the three-jaw chuck 9 is used to clamp the large bar. When processing a bar of different diameters, first install the corresponding semicircular die se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com