Aligning station device

A station and clamping block technology, applied in the field of normalization station devices, can solve the problems of broken vacuum, products cannot be firmly sucked, and adsorbed to the edge of the carrier, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, specific implementations are now described in detail.

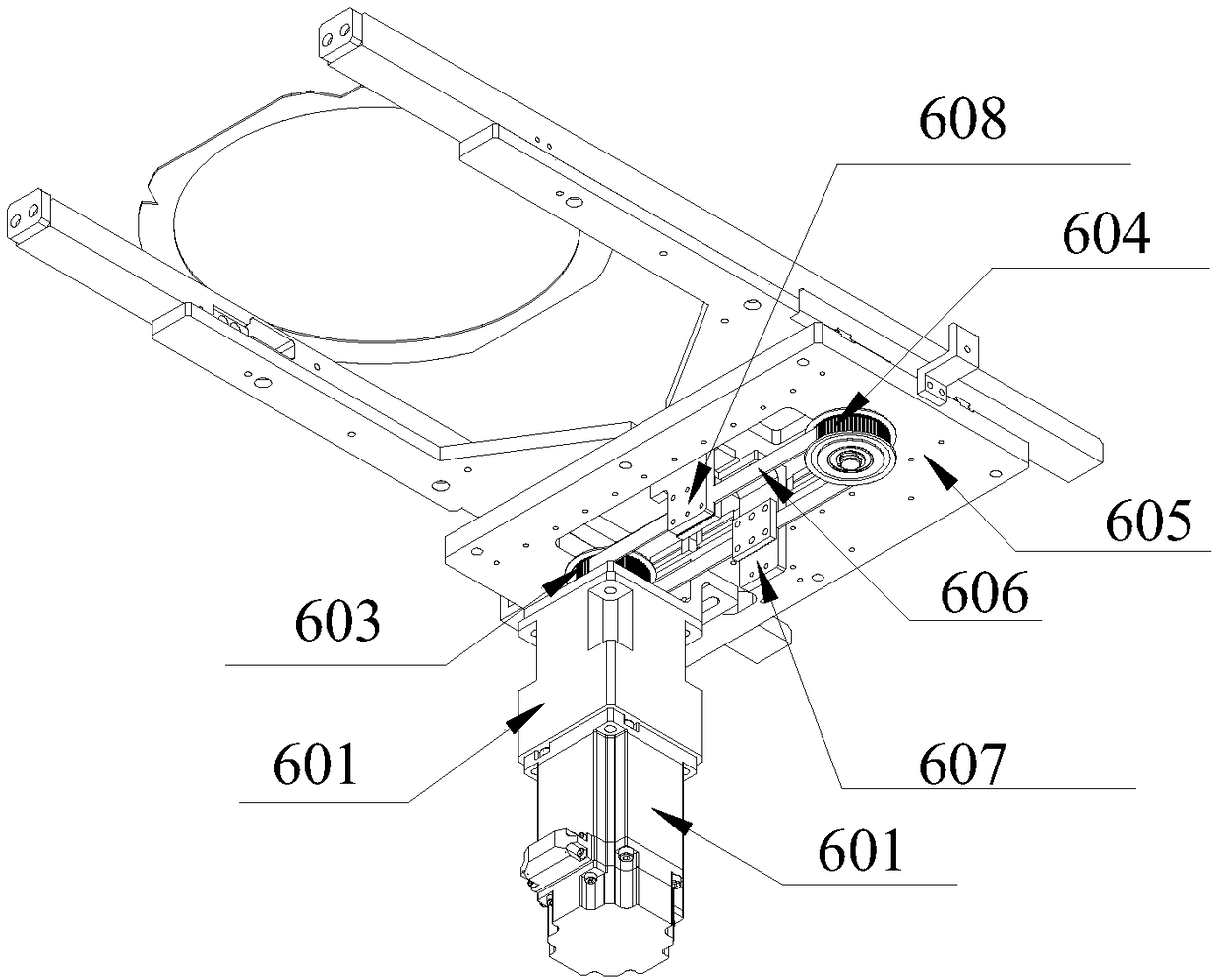

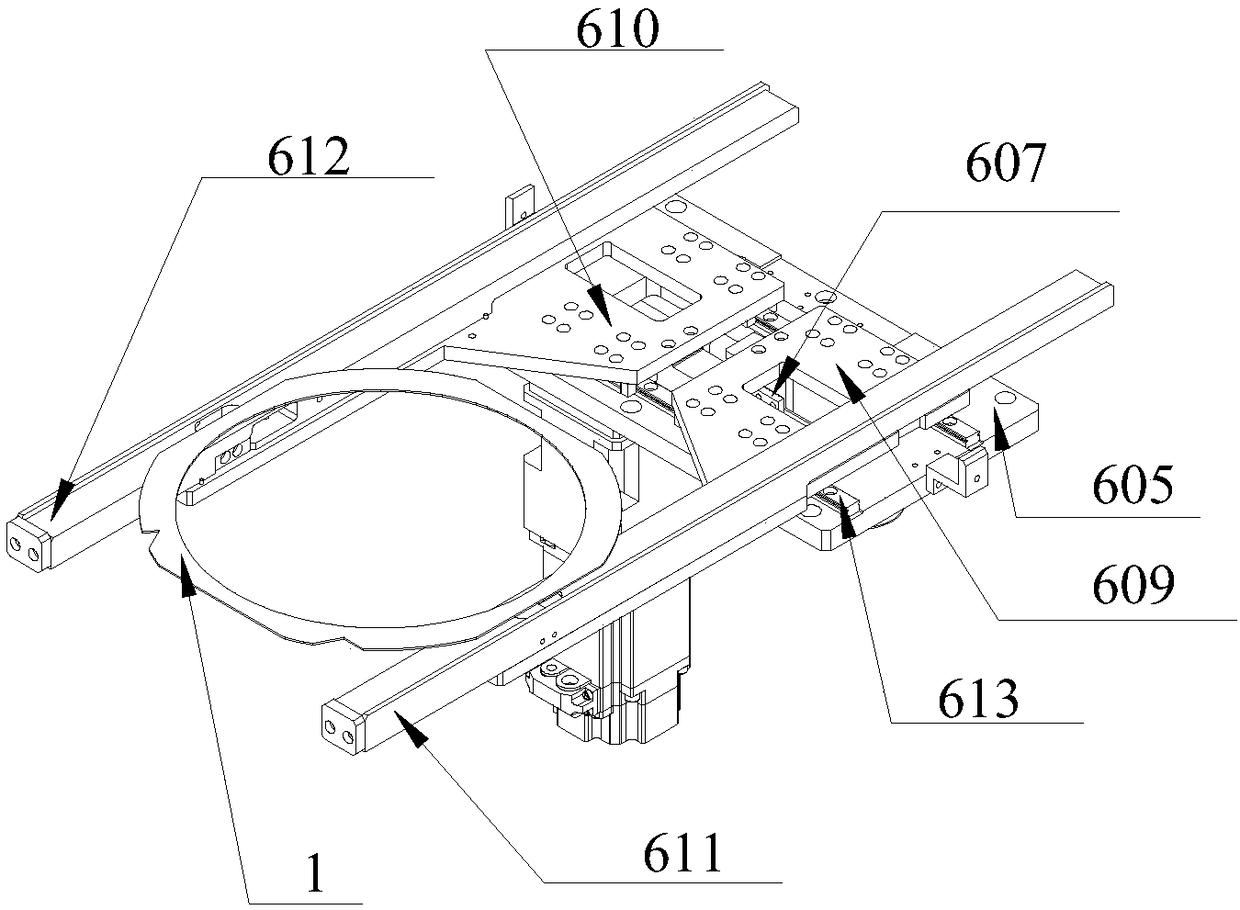

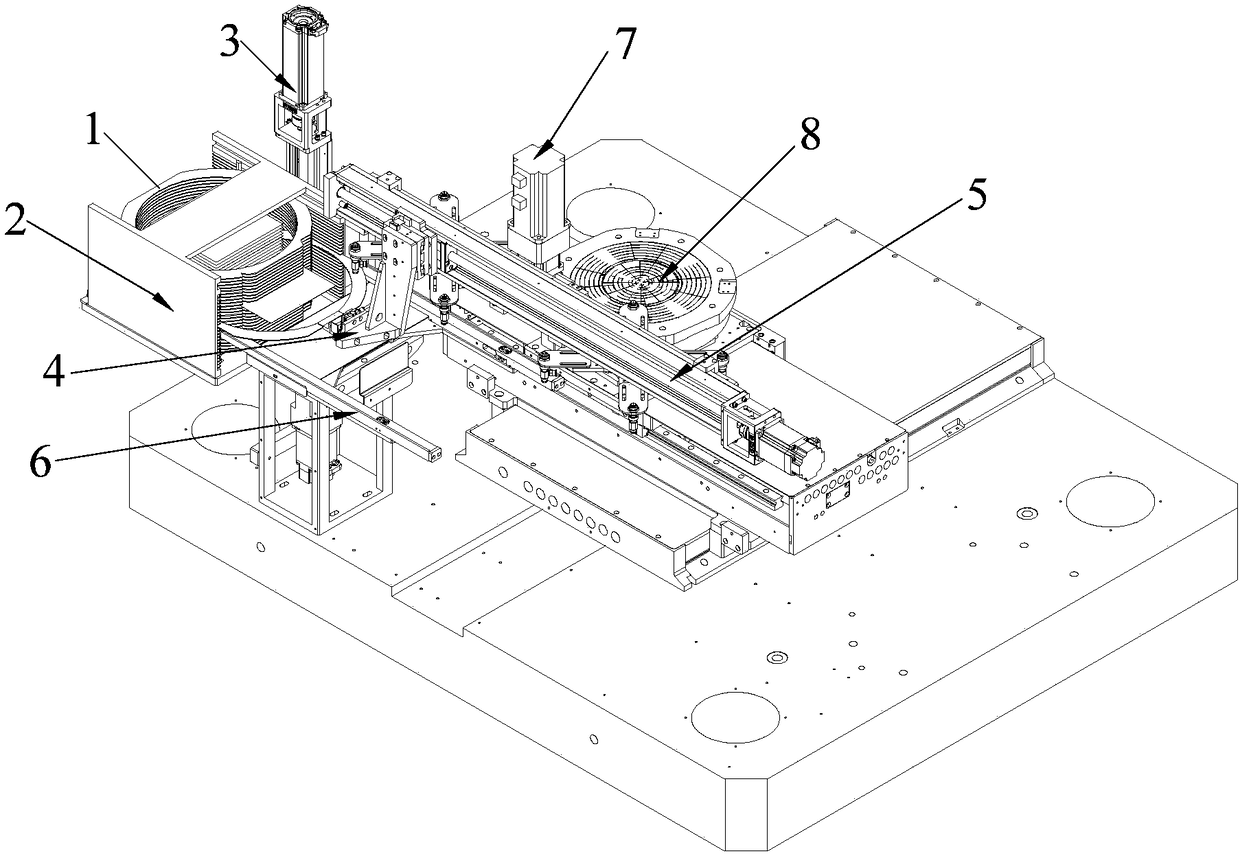

[0032] like figure 1 , figure 2 As shown, the normalizing station device includes a driving wheel 603, a driven wheel 604, a synchronous belt 606, a first clamping block 607, a second clamping block 608, a left sliding plate 610, a right sliding plate 609, a normalizing left retaining strip 612, a normalizing The right bar 611 and the base plate 605, the driving wheel 603 and the driven wheel 604 are all rotatably supported on the bearing seat, the bearing seat is installed on the base plate 605, the timing belt 606 is set on the driving wheel 603 and the driven wheel 604, and the timing belt One side of 606 installs the first clamping block 607, and the other side of synchronous belt 606 installs the second clamping block 608, and the first clamping block 607 and the second clamping block 608 are me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com