Three elastic band rail gun barrel type launching mechanism

A launching mechanism and cannon-barrel technology, which is applied to the field of three-rubber rail cannon-barrel launching mechanisms, can solve the problems of inability to achieve the purpose, not to mention application, and inaccurate investment and installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing, structure and working principle of the present invention will be further described:

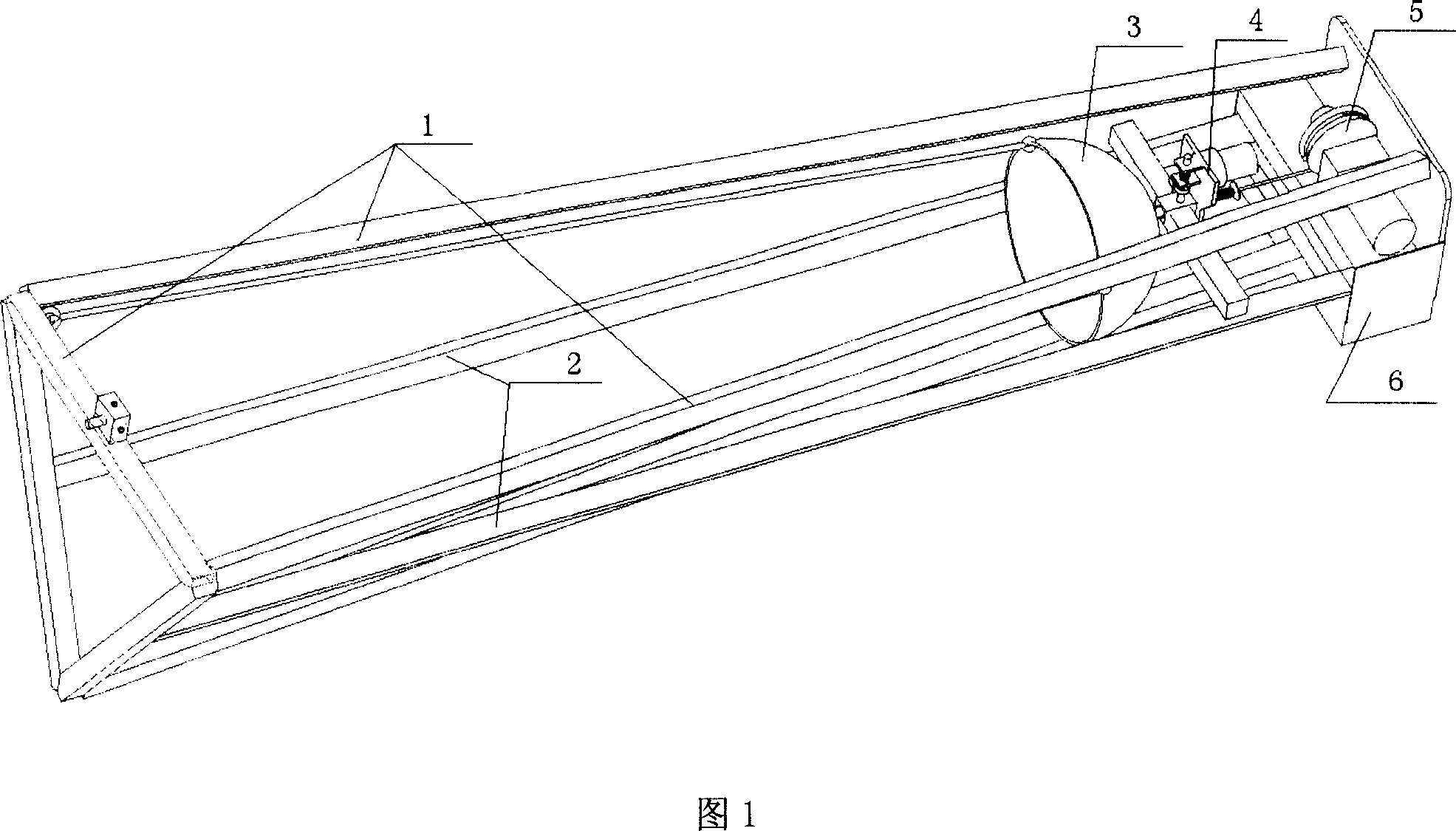

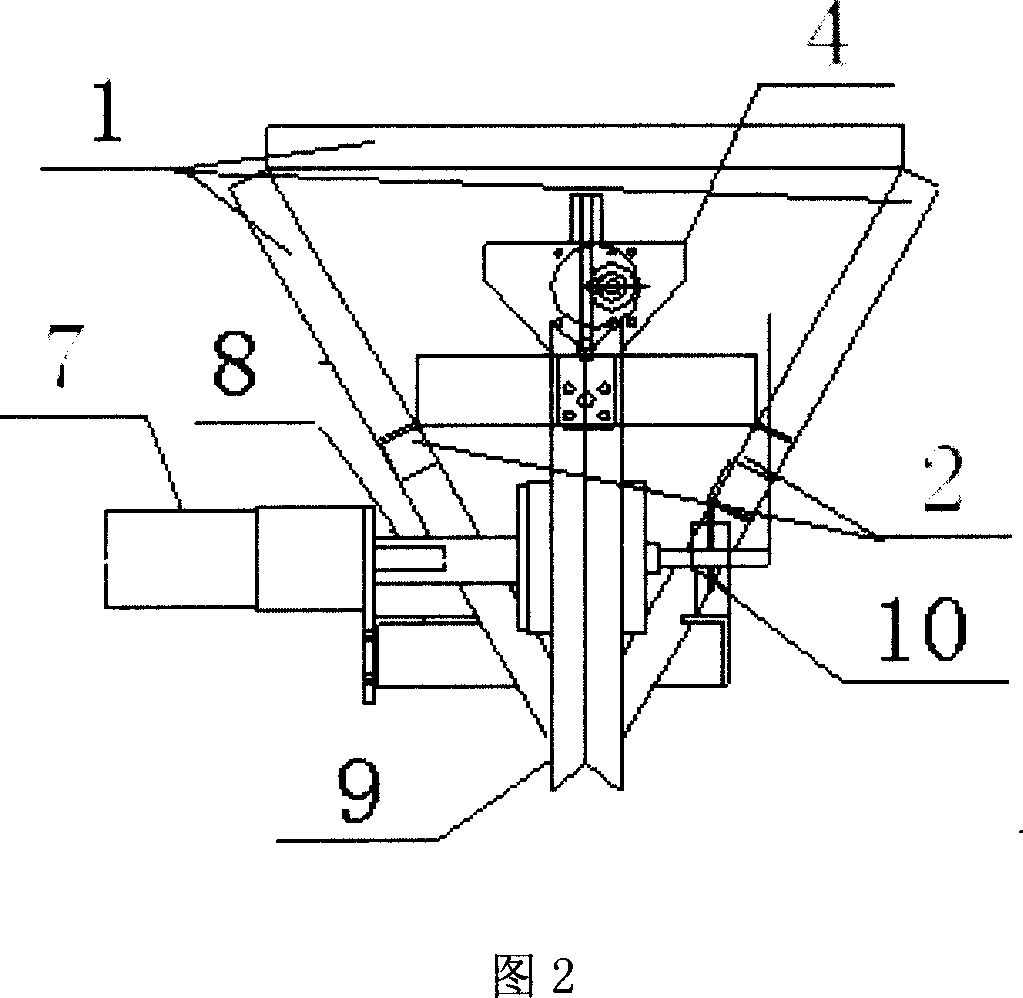

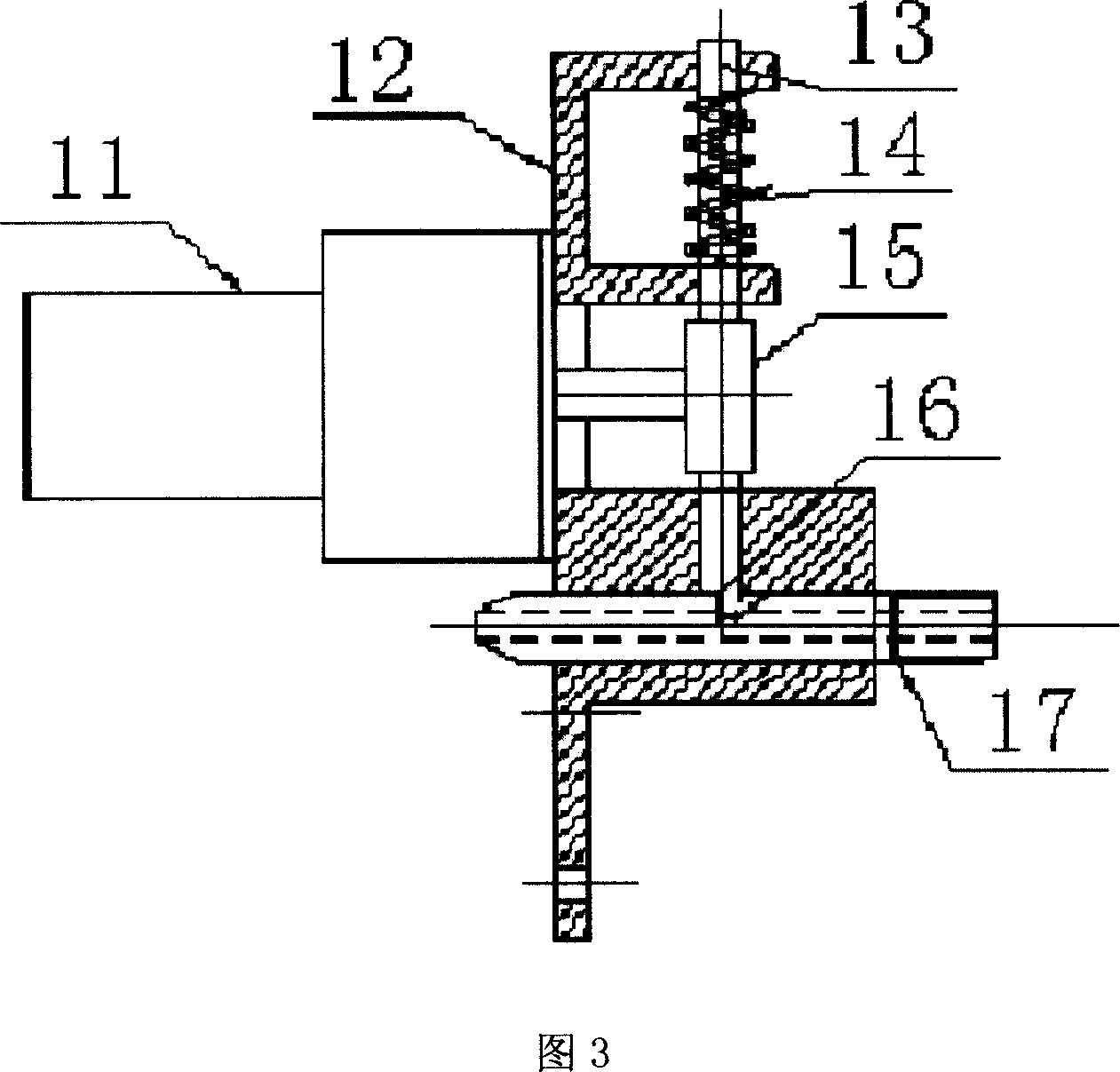

[0028] The present invention comprises a frame 1 and an ejection track 2, a reel and pay-off mechanism 5, a trigger mechanism 4 and a ball loading mechanism 3, the motor 7 of the reel and pay-off mechanism 5 is connected to the reel 9 through a coupling 8, and the reel 9 Both ends are fixed on the base 6, one end of the ball-loading mechanism 3 is connected to the wrapping rod 17 of the trigger mechanism 4, the wrapping rod 17 is connected to the steel wire 18 and the reel and pay-off mechanism 5 is connected, and the other end is passed through three rubber bands 21, 22 , 23 are connected with the front end of the frame 1, and the motor 11 of the trigger mechanism 4 is connected to the cam 20 and fixed on the support 12. Wherein, the frame 1 and the ejection track 2 are triangular, one side of the reel 9 is provided with a small pull str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com