Method and apparatus for centering lens aligner

A centering device and lens technology, which is applied to the grinding drive device, the components of the grinding machine, the control of the workpiece feed movement, etc. and other problems, to achieve the effect of high centering accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

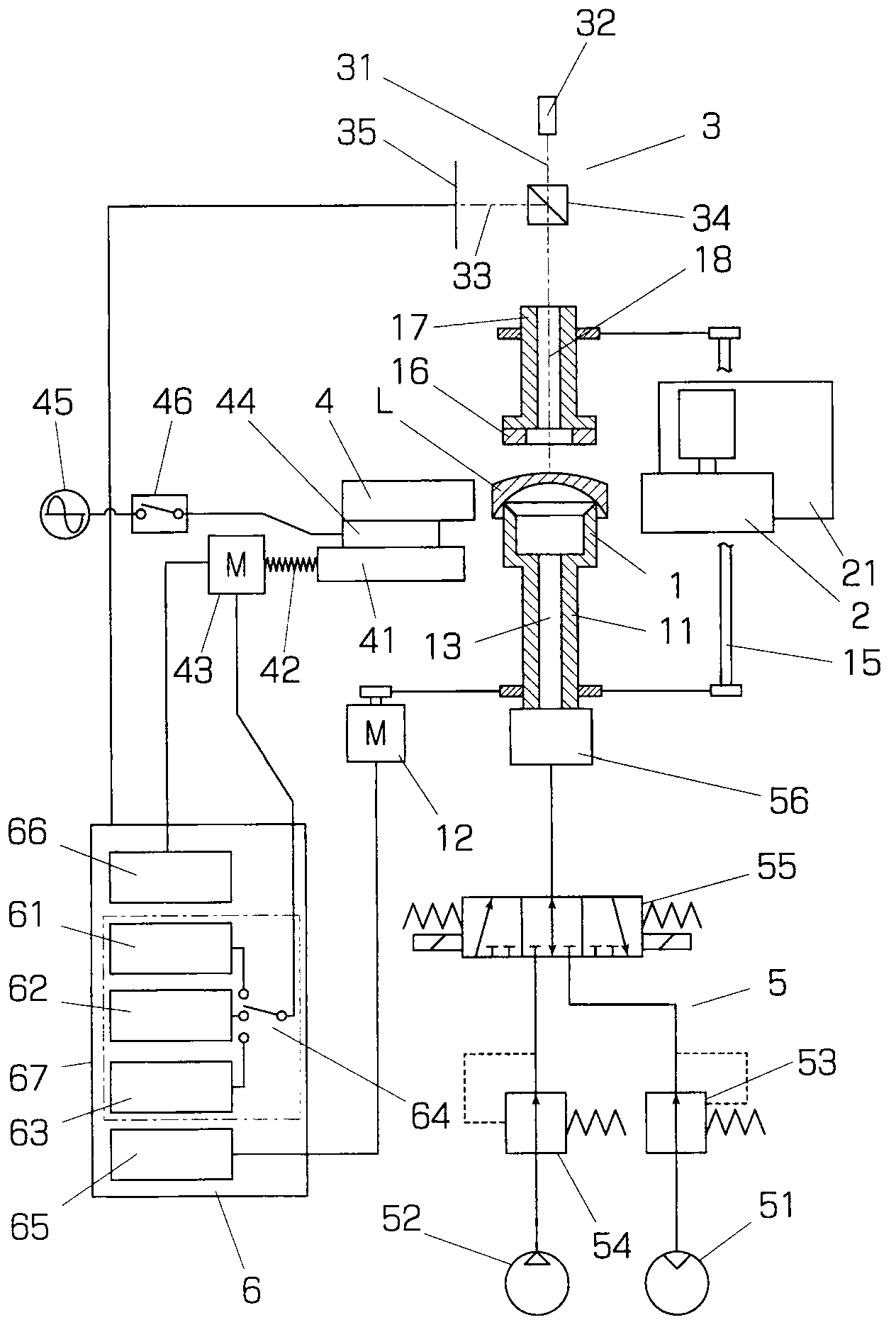

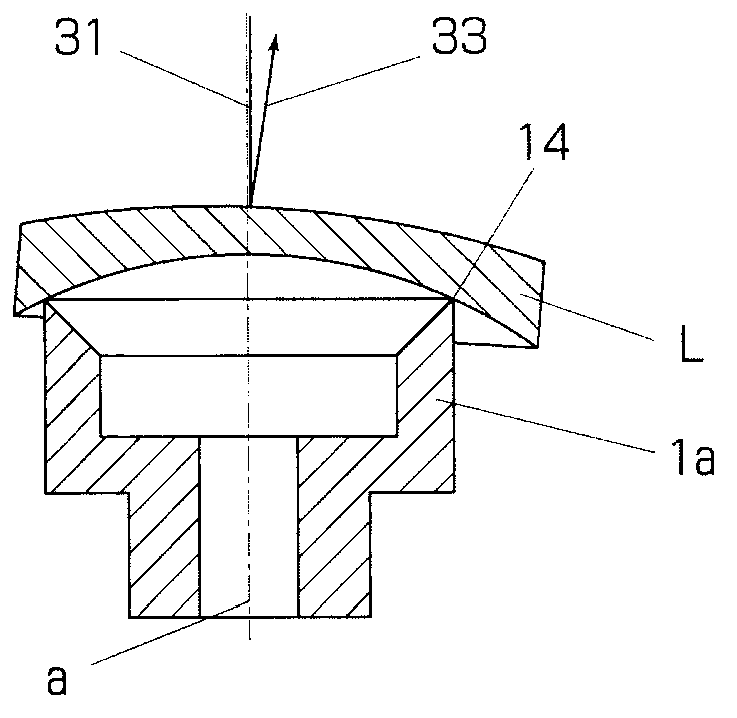

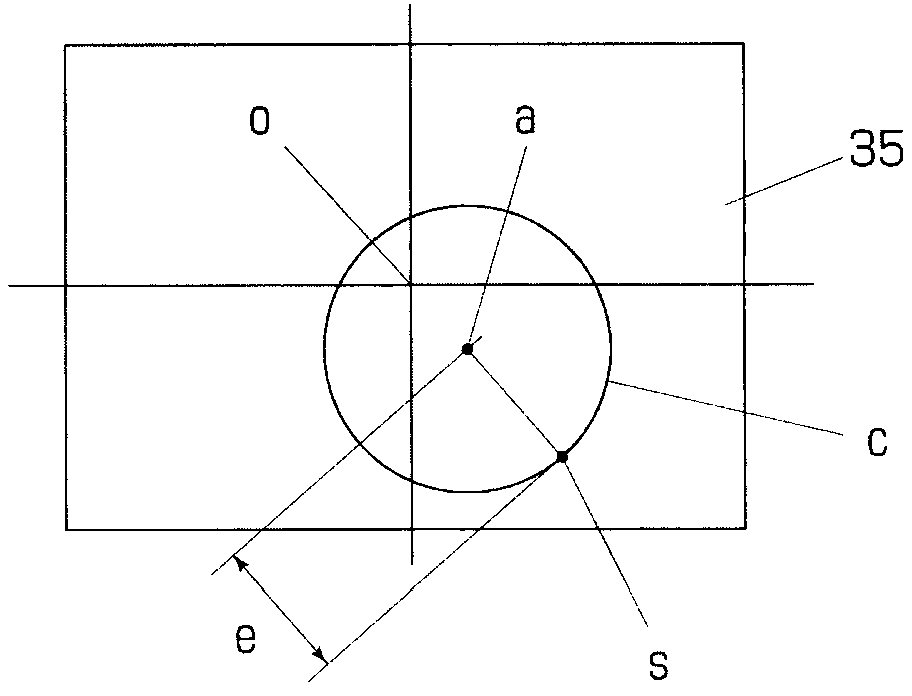

[0030] Hereinafter, embodiments of the invention will be described with reference to examples shown in the drawings. The aligning machine of the illustrated embodiment has: the main shaft 11, which is equipped with an upward cup-shaped cage 1 (corresponding to Figure 10 , 11The component of the cage 1a in the existing structure); the upper shaft 17, which is equipped with an annular pressing pad 16 opposite to the cage 1 at the lower end; The outer periphery of the lens L held by clamping is processed. The main shaft 11 and the upper shaft 17 are arranged on the main shaft axis a in the vertical direction, and are synchronously driven by the main shaft motor 12 and the connecting shaft 15 that rotatably connects the main shaft 11 and the upper shaft 17 . Therefore, the cage 1 and the pad 16 rotate synchronously around the axis a. The upper shaft 17 can be raised and lowered by an elevating device not shown, and the lens L is loaded on the holder 1 in the state where the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com