Ball screw axial runout rapid detection device

A technology for axial runout and detection devices, applied in measuring devices, mechanical measuring devices, mechanical devices, etc., can solve the problems of low accuracy, complicated operation, unfavorable installation, fixation and operation, etc., and achieve strong practicability and easy operation Simple, fast detection of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

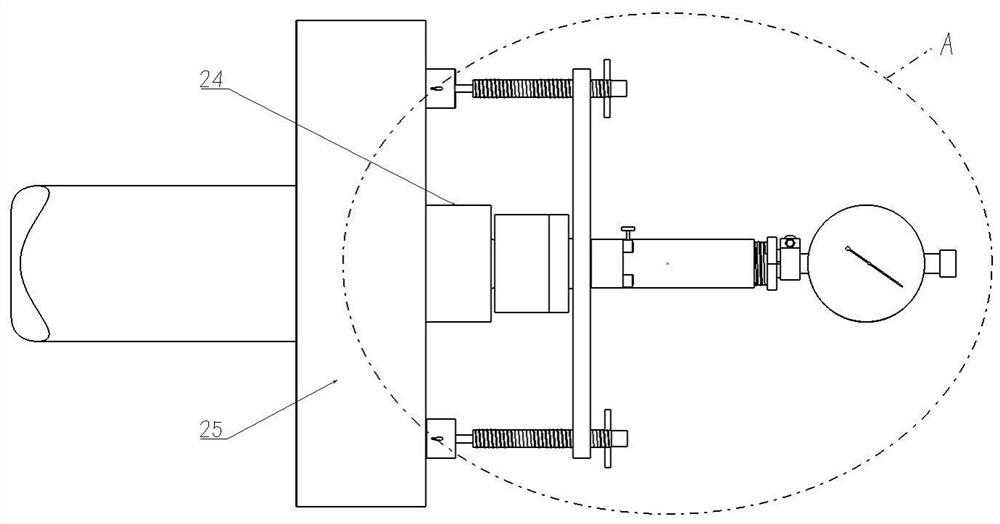

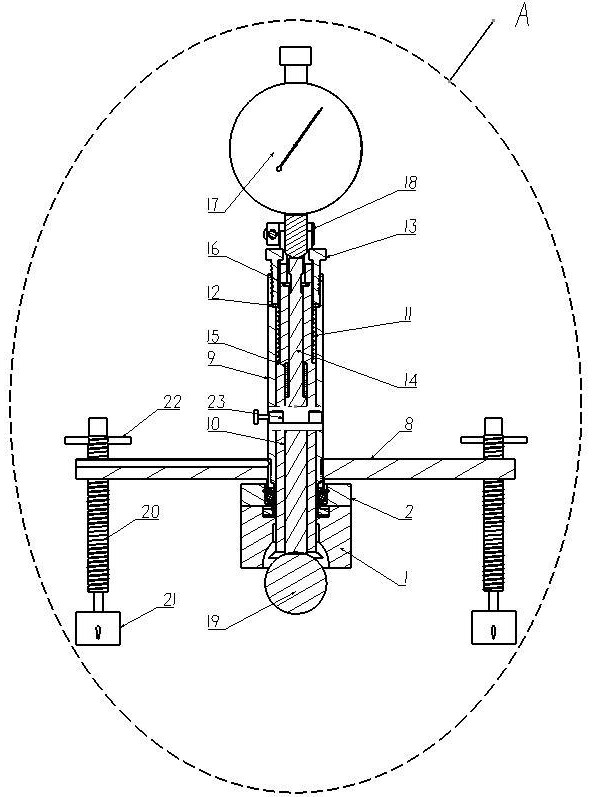

[0054] A quick detection device for the axial runout of a ball screw, such as figure 1 As shown, it includes a high-precision sphere 19, a rotating and separating mechanism installed on the end surface of the screw 24 for separating circular motion, a preload adjustment mechanism for pre-tightening the high-precision sphere 19 to fit the center hole wall of the screw 24, and precision measurement. Mechanism and support assembly, the preload adjustment mechanism is installed on the end face of the lead screw 24 through the support assembly, the preload adjustment mechanism is connected to the rotation separation mechanism; touch.

[0055] It should be noted that during assembly, the support assembly is first installed on the preload adjustment mechanism, and then the preload adjustment mechanism is connected with the rotary separation mechanism, and then the precision measuring mechanism is installed into the preload adjustment mechanism. The sphere 19 and the dial indicator 1...

Embodiment 2

[0057] This embodiment is optimized on the basis of embodiment 1, such as figure 1 , figure 2 As shown, the precision measuring mechanism includes a mandrel 14 and a dial indicator 17, and the preload adjustment mechanism is set in the rotation separation mechanism and fits with the high-precision sphere 19 through the rotation separation mechanism; the preload adjustment mechanism There is a mandrel 14 slidingly sleeved in the mechanism, and one end of the mandrel 14 protrudes and contacts with a high-precision sphere 19. The dial indicator 17 is installed in the inner cavity of the upper end surface of the pre-tightening adjustment mechanism, and the measuring head and the core The other end of the shaft 14 is in contact.

[0058] During the use of the present invention, the detection device is installed on the end face of the lead screw 24. The device uses a powerful magnetic base 1 to quickly fix the end face of the lead screw 24, and the rotation of the lead screw 24 is...

Embodiment 3

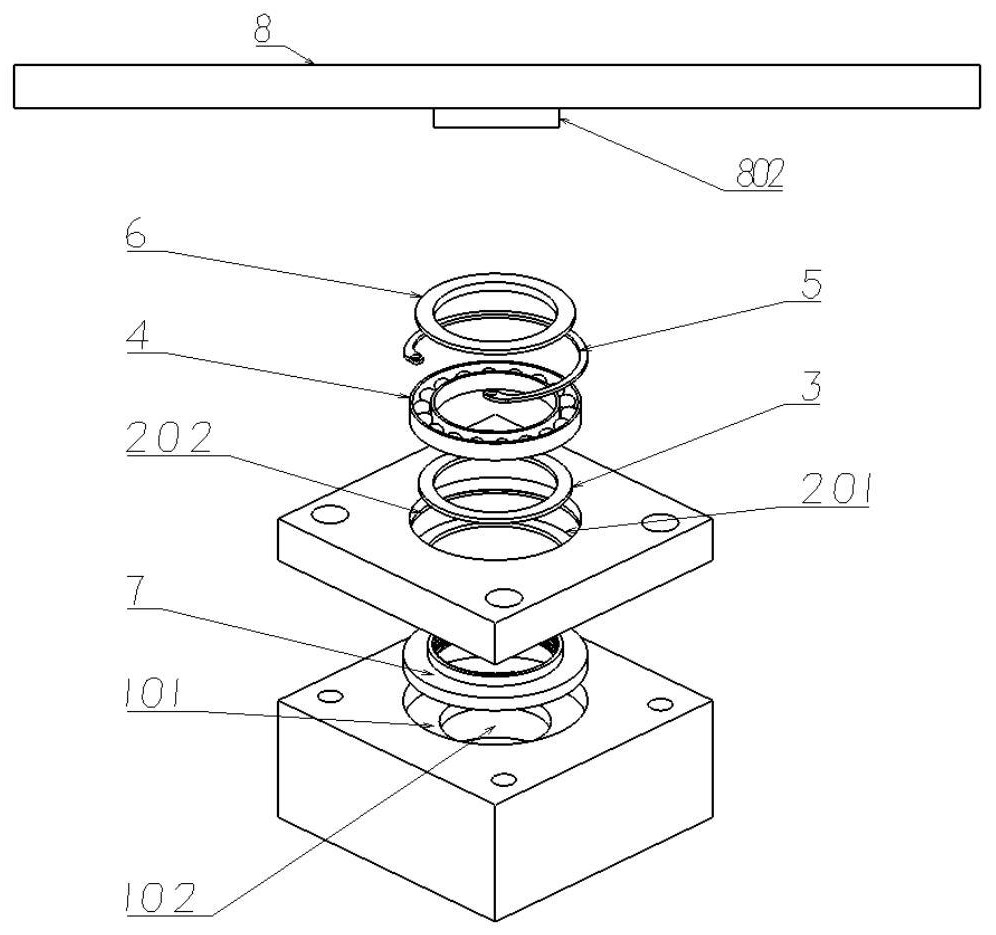

[0061] This embodiment is optimized on the basis of embodiment 1 or 2, as image 3 As shown, the rotating separation mechanism includes a strong magnetic base 1, a bearing base 2, a bearing 4, and a sleeve lock nut 7; Nut 7, the powerful magnetic seat 1 is threadedly connected with the bearing base 2, and the preload adjustment mechanism passes through the support assembly, the bearing 4 and extends into the bearing base 2 and is threadedly connected with the sleeve lock nut 7; the bearing 4 is installed in the bearing base 2, the inner ring of the bearing 4 fits with the preload adjustment mechanism, and the outer ring is fixedly connected with the inner cavity of the bearing base 2, and the support assembly is provided with a device to limit the rotation of the preload adjustment mechanism Limit screw.

[0062] Further, the cavity of the bearing base 2 is provided with a boss 201 for installing the bearing washer 3 and a limit groove 202 for installing the limit ring 5, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com