Tool for deburring orifice of small hole communicated with inner wall of deep hole

A deburring knife and deburring technology, which is applied in the field of tool devices, can solve the problems of uneven deburring, easy to bruise the hole wall, poor effect, etc., and achieve uniform chamfering of the orifice, stable contact stress, and accurate centering Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Describe the present invention in detail below in conjunction with accompanying drawing:

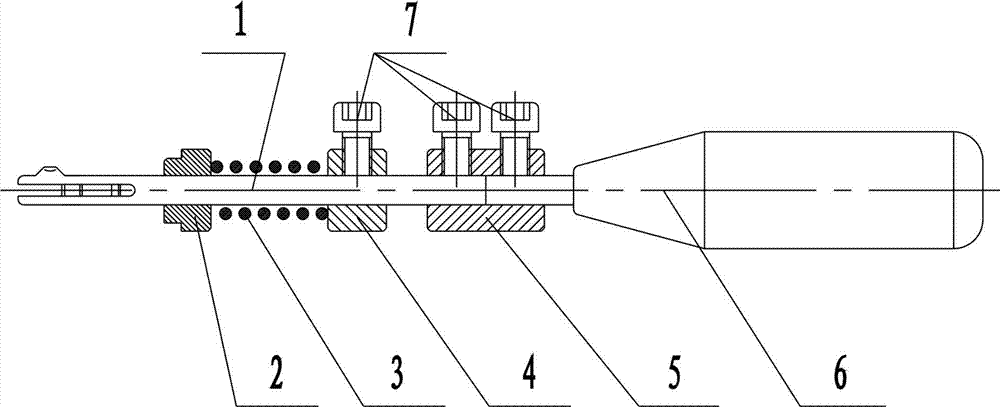

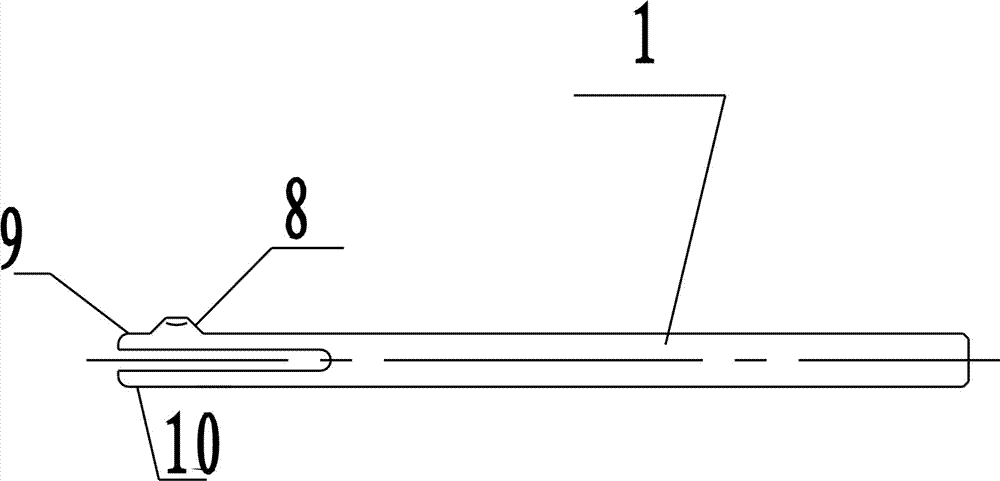

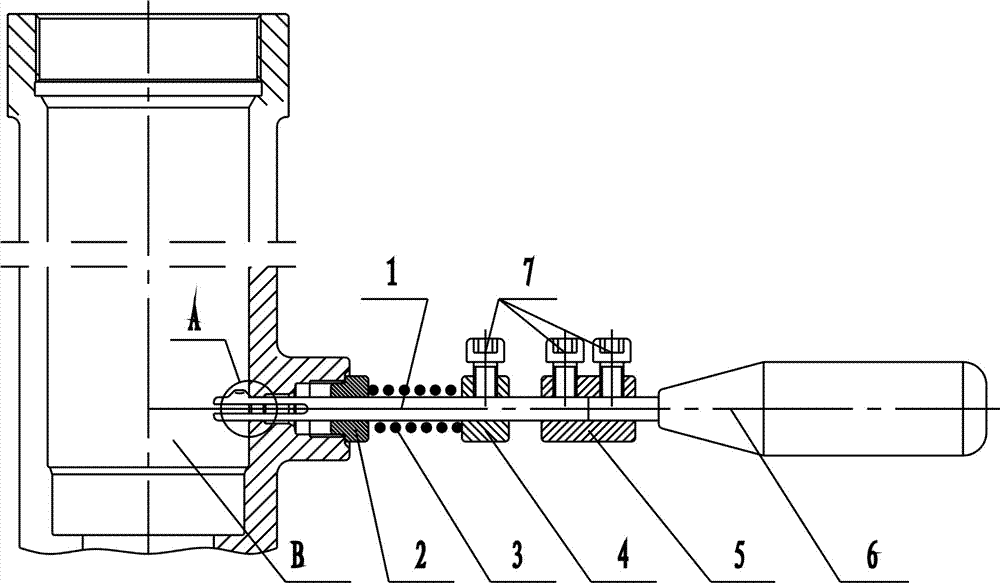

[0014] like figure 1 and figure 2 As shown, a tool for deburring the inner wall of a deep hole intersecting small holes, including a deburring knife 1 and a handle 6 . like figure 2 As shown, the deburring knife 1 includes a knife shaft and a blade portion, the blade portion is in the shape of a fork, and the fork portion has two fork branches 9 and 10 . The forks 9 and 10 are elastic forks, that is, the distance between the two forks can be slightly changed with the action of external force. And the outer side of the fork branch 9 is provided with a cutting edge 8 . like figure 1 As shown, handle 6 can directly adopt screwdriver handle. But described screwdriver shank needs the screwdriver head to be cut off. One end of the burr knife bar is connected with the end of the handle through the connecting sleeve 5, and is fixed with a stop screw 7. like figure 1 As shown, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com