Device and method for automatically stacking and packaging bricks

A technology of bricks and device groups, applied in packaging, building materials packaging, transportation and packaging, etc., can solve the problems of closed factories, low willingness to cooperate with people, and high wages, so as to reduce the waste of human resources and increase the value of industrial use. , The effect of improving the molding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

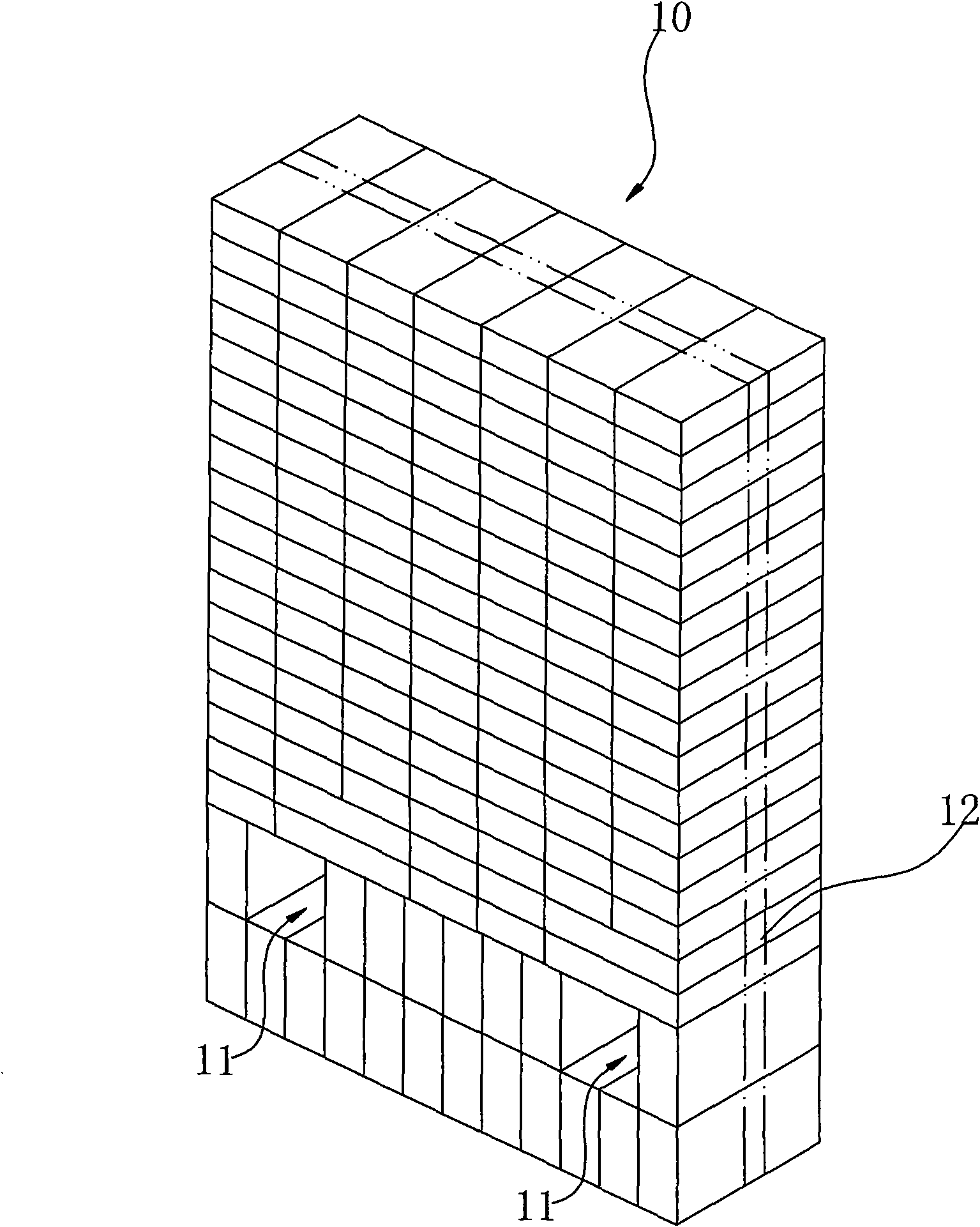

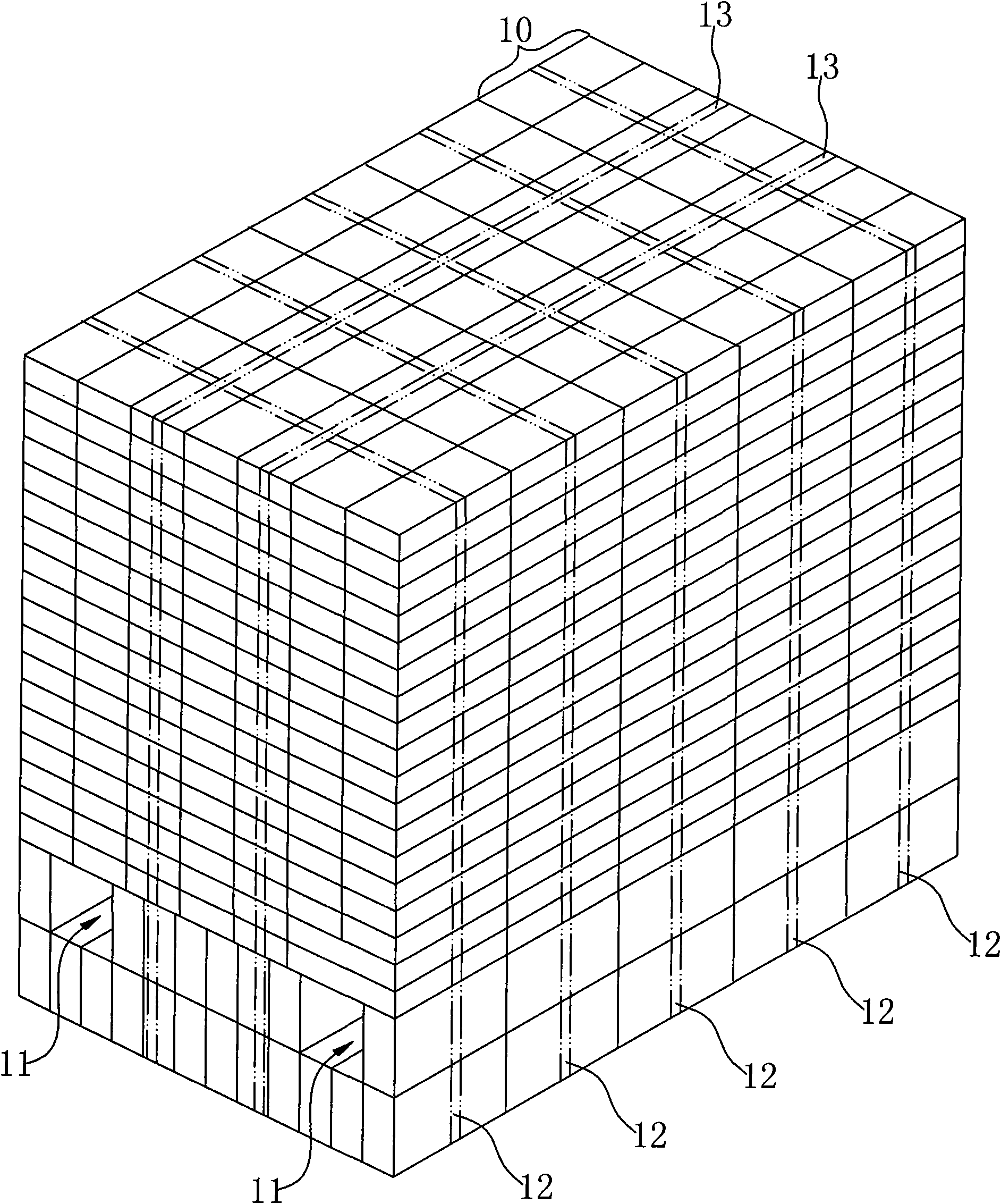

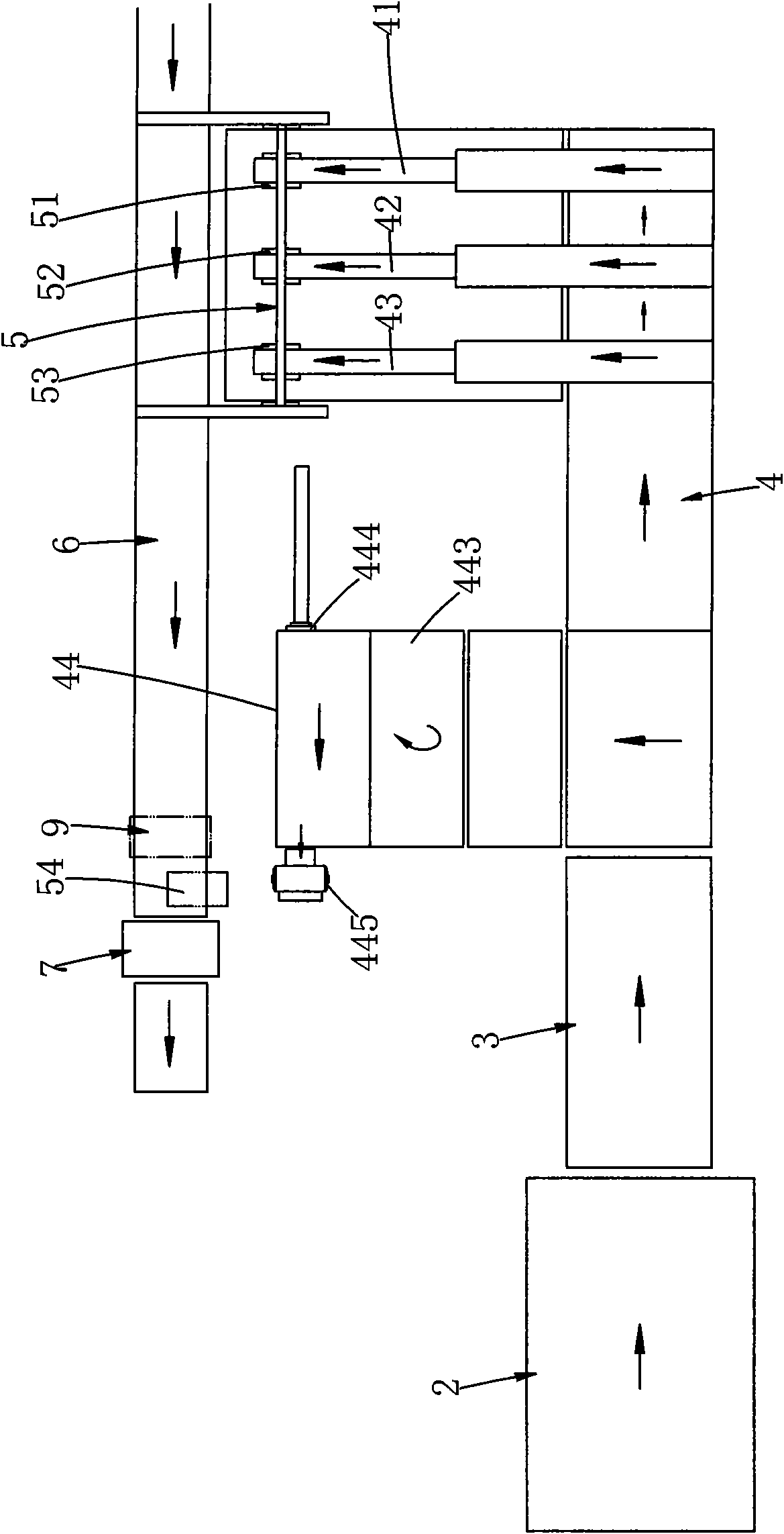

[0073] First, see image 3 As shown, the present invention mainly includes: a tray receiving device 2, an alignment device 3, a separate conveying and stacking device group 4, a suspension hook device group 5, a conveyor belt 6 and other devices, wherein:

[0074] Connecting device 2, please refer to Figure 4 As shown, one side thereof is provided with a driving roller 21, and the two ends of the driving roller 21 are fixedly provided with a driving gear 211, and a driving motor 212 is established in the center of the driving roller 21, and the lower edge of the driving roller 21 is fixed in parallel. A clamping plate 213 is provided, and the upper edge of the two ends of the clamping plate 213 is connected to the driving oil pressure rod 214; the other side of the connecting plate device 2 is provided with a driving roller 22, and the two ends of the driving roller 22 are fixed with a driving gear 221 , and a driving motor 222 is set in the center of the driving roller 22, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com